Enhancing Industry Independence with Cutting-Edge PCB Technology

Focusing on high-end and automation

PCBs (printed circuit boards) are to the electronics industry what steel is to real estate and asphalt is to roads and bridges.

At the beginning of the 21st century, the dawn of China's electronics industry sounded in Shenzhen. Japanese, Korean, and Taiwanese companies expanded their territories in South China, pressing the accelerator for China's electronic manufacturing industry. At that time, the most fundamental part of the industry chain and the demand for massive PCBs made it the first entry point for Chinese electronic industry practitioners to start their own businesses.

Focusing on high-end PCBs and serving display panel companies became the path to success for Li Xiaohua in their uninterrupted 20-year entrepreneurial journey.

Targeting the high-end market

"Printed circuit boards are the most fundamental components of the electronic manufacturing industry, known as the 'mother of electronic products.' Mobile phones, tablets, and other electronic consumer goods, as well as various other industries such as artificial satellites, spacecraft, airplanes, ships, and even the current new energy vehicles, cannot do without the application of electronic products. Circuit boards are the carriers for all electronic product applications. Therefore, when we chose to enter this industry, we believed that it had broad future applications and significant development potential," explained Li Xiaohua, Chairman.

At the beginning of the 21st century, lightweight electronic products such as smart wearable devices began to gain popularity, and the demand for PCBs shifted towards lighter and more flexible directions. At that time, multi-touch screens represented by the Nintendo NDS game console became a global sensation. In 2004, Apple internally initiated the "Purple2" project, shifting the company's focus from iPods and iPads to large-screen touch smartphones. The "Purple2" project eventually led to the creation of the iPhone series.

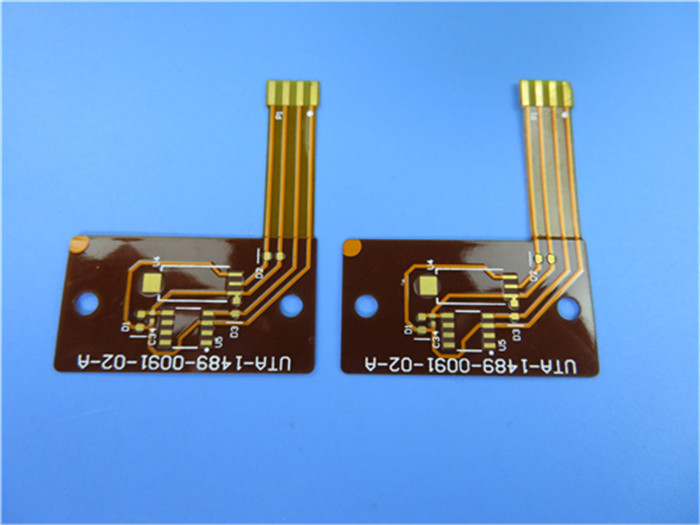

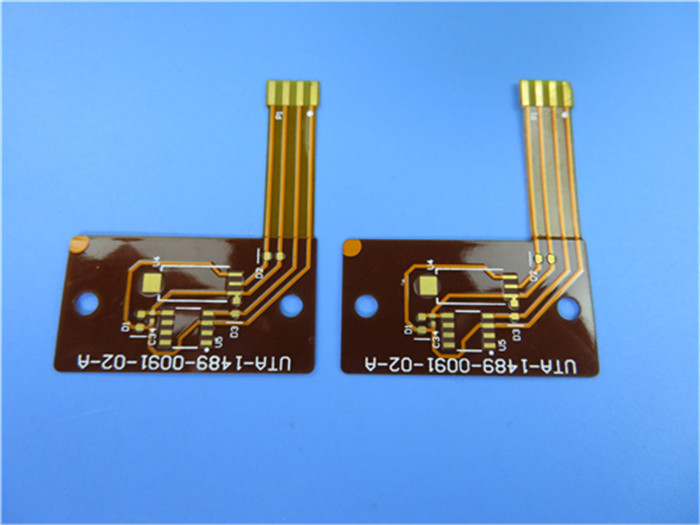

Manufacturing smartphones is like "building a dojo inside a snail's shell," and circuit boards, as basic electronic components, also started to require lightweight, flexible designs while overcoming various extreme conditions. Li Xiaohua noticed this trend and ultimately decided to focus on Flexible Printed Circuit (FPC) as PCB supplier' entrepreneurial direction.

"Flexible circuit boards are used in scenarios like phone screens, laptop screens, and tablet screens. So, at that time, we conducted a detailed market analysis and ultimately determined to serve the entire display panel industry," said Li Xiaohua.

Entering the Chip-on-Film (COF) industry marked the beginning ofPCB supplier' foray into the high-end market.

"Starting in 2016, FPC began to develop towards lighter, thinner, and finer lines. The flexible narrow board for driving display panels became representative of these fine lines. This product was largely a blank space in China and mainly supplied by Korean, Japanese, and Taiwanese companies, with only five such suppliers globally. The line width of COF products is only 8 to 10 micrometers, while the line width of ordinary FPCs at that time was still around 50 to 60 micrometers. Therefore, COF products represent the ceiling for fine-line flexible circuit boards.

With this in mind,PCB suppliers, with its new direction, began actively seeking change. In 2016, high frequency PCB suppliers acquired the Japanese company Flexceed, successfully entering the COF product field.

Focusing on raw materials and enhancing industry independence

Different from traditional PCBs that use epoxy resin as the conventional material, FPC and COF use high-end electronic-grade Polyimide (PI) as the raw material. However, electronic-grade PI, as a raw material, has high technological difficulties, and its sources are monopolized by overseas manufacturers.

Recognizing this issue, Li Xiaohua started to layout the company's PI business.

"PI is an insulating material used in both FPC and COF. In fact, PI is the most challenging material to develop," pointed out Li Xiaohua. "Flexible circuit boards have very high requirements for material expansion and contraction rates, especially for COF. Due to its fine lines, COF has extremely strict dimensional requirements, with an expansion and contraction rate below 0.0002."

Currently,some PCB suppliers are cooperating with research institutes affiliated with the Chinese Academy of Sciences to develop PI material formulas and achieve industrialization.PCB industry is expected to help domestic flexible circuit board companies, includingBicheng, steadily improve their self-sufficiency in PI demand.

"The overall level of our country's electronic manufacturing industry, including the entire industrial sector, actually lags behind foreign countries not in the processing link but in equipment and upstream raw materials. We are not in the equipment business, but as a processing industry, we believe that developing widely used materials in the upstream should also be our responsibility," emphasized Li Xiaohua.

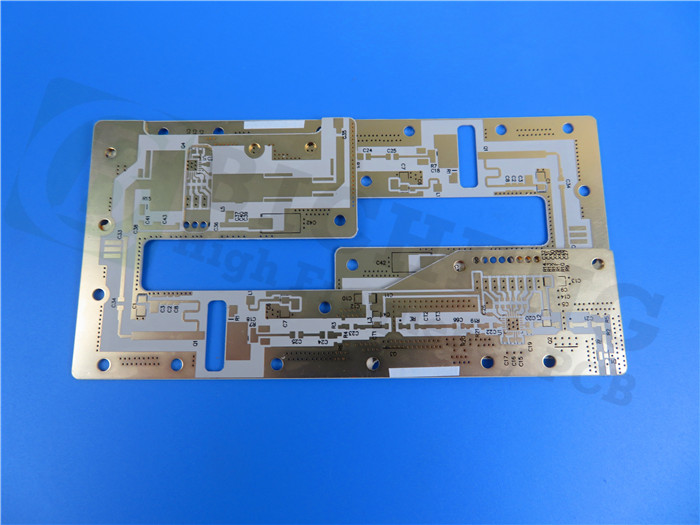

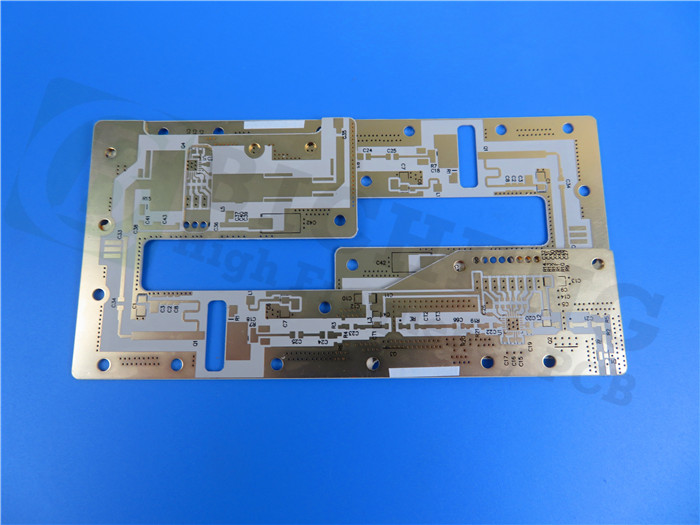

Introducing the newly shipped PCB-RT/duroid 6035HTC

In line with their commitment to providing high-quality PCB solutions,Bicheng is pleased to introduce their latest product, the RT/duroid 6035HTC 20mil PCB. This high-frequency circuit material is a ceramic-filled PTFE composite specifically designed for high-power RF and microwave applications, making it an exceptional choice for demanding high-power applications.

One of the standout features of the RT/duroid 6035HTC PCB is its impressive thermal conductivity, which is almost 2.4 times higher than standard RT/duroid 6000 products. This enhanced thermal conductivity allows for improved dielectric heat dissipation, enabling lower operating temperatures for high-power applications. Additionally, the copper foil used in the PCB has excellent long-term thermal stability, ensuring reliable performance even under challenging thermal conditions.

The RT/duroid 6035HTC boasts excellent electrical properties as well. It has a dielectric constant (DK) of 3.5 +/- 0.05 at 10 GHz/23°C, ensuring reliable signal transmission at high frequencies. With a low dissipation factor of 0.0013 at 10 GHz/23°C and a thermal coefficient of dielectric constant (TCDk) of -66 ppm/°C, this PCB material offers excellent high-frequency performance and stability over a wide temperature range.

Furthermore, the RT/duroid 6035HTC exhibits a low moisture absorption rate of just 0.06%, ensuring its reliability in humid environments. The material's thermal conductivity of 1.44 W/m/K at 80°C contributes to its excellent heat dissipation capabilities. Additionally, the coefficient of thermal expansion (CTE) values in the X, Y, and Z axes (19 ppm/°C, 19 ppm/°C, and 39 ppm/°C, respectively) provide dimensional stability and reliability for the PCB.

The advanced filler system used in the RT/duroid 6035HTC PCB offers several benefits. Firstly, it enables excellent drillability, reducing drilling costs compared to standard high thermally conductive laminates that use alumina fillers. Secondly, it extends tool life, resulting in improved efficiency and reduced manufacturing downtime.

The PCB stackup for the Rogers 6035HTC is a 2-layer rigid PCB, with copper layers of 35 μm on both sides. The RT/duroid 6035HTC layer has a thickness of 0.508 mm (20 mil), providing a robust and reliable substrate for high-power applications. The finished board has a thickness of 0.6 mm and a finished copper weight of 1 oz (1.4 mils) on the outer layers. The via plating thickness is 20 μm, ensuring excellent electrical connectivity throughout the board.

With a worldwide availability, the RT/duroid 6035HTC high frequency PCB from Bicheng is ready to meet the needs of various industries and applications. Its high thermal conductivity, low loss tangent, thermally stable copper foil, and advanced filler system make it an ideal choice for high-power RF and microwave amplifiers, power amplifiers, couplers, filters, combiners, and power dividers.

We continue to push the boundaries of PCB technology, providing reliable and high-performance solutions to their customers worldwide. With their focus on quality, innovation, and industry independence, they are poised to make a significant impact in the rapidly evolving electronics manufacturing landscape.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com