Advancements in PCB

Manufacturing Propel Industry into New Frontiers

The

PCB industry is undergoing a transformative phase, driven by groundbreaking

advancements and cutting-edge technologies that are propelling the industry

into new frontiers.

Miniaturization and High-Density Interconnects:

The

demand for smaller, lighter, and more powerful electronic devices continues to

rise. To meet these evolving needs, PCB manufacturers are pushing the

boundaries of miniaturization and high-density interconnects. Advanced

fabrication techniques such as microvias, blind vias, and buried vias, along

with finer trace and space requirements, enable the creation of compact PCB

designs with enhanced functionality, enabling the next generation of consumer

electronics, wearable devices, and IoT applications.

Flexible and Rigid-Flex PCBs:

Flexible

and rigid-flex PCBs are witnessing a surge in popularity due to their ability

to conform to complex shapes and provide greater design flexibility. With the

advent of flexible substrates and advanced assembly techniques, PCB

manufacturers are delivering innovative solutions for applications in

industries such as automotive, aerospace, medical, and consumer electronics.

The integration of flexible and rigid sections eliminates the need for

connectors, reducing assembly time, improving reliability, and enabling new

product form factors.

High-Speed and High-Frequency PCBs:

The

relentless pursuit of faster data transfer rates and increased signal integrity

has spurred advancements in high-speed PCB and high-frequency PCB technologies.

Designers and engineers are leveraging specialized materials, controlled

impedance routing, and advanced signal integrity analysis to achieve optimal

performance in applications such as telecommunications, data centers,

automotive radar systems, and 5G infrastructure. These advancements enable the

efficient transmission of high-speed digital signals and the handling of

ever-increasing frequencies.

Advanced Materials and Substrates:

The

availability of advanced materials and substrates is revolutionizing the PCB

industry. Next-generation materials, such as high-frequency laminates,

high-speed digital materials, and thermally conductive substrates, offer

improved electrical performance, signal integrity, thermal management, and

reliability. These materials enable the design and manufacture of PCBs that can

withstand demanding operating conditions, including high temperatures,

high-frequency signals, and power dissipation requirements.

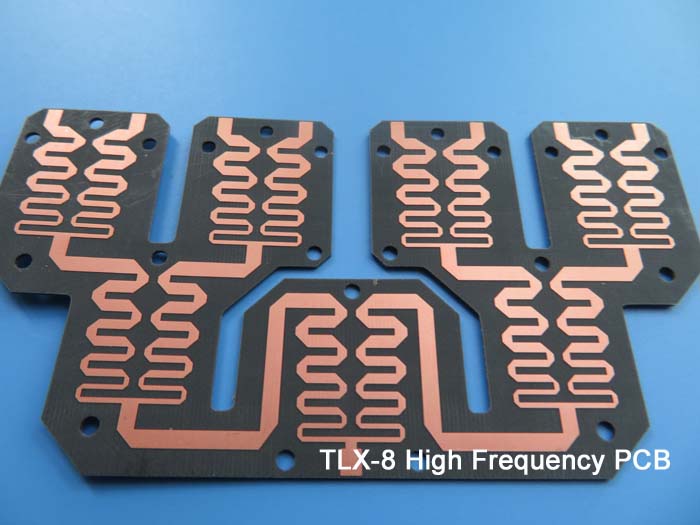

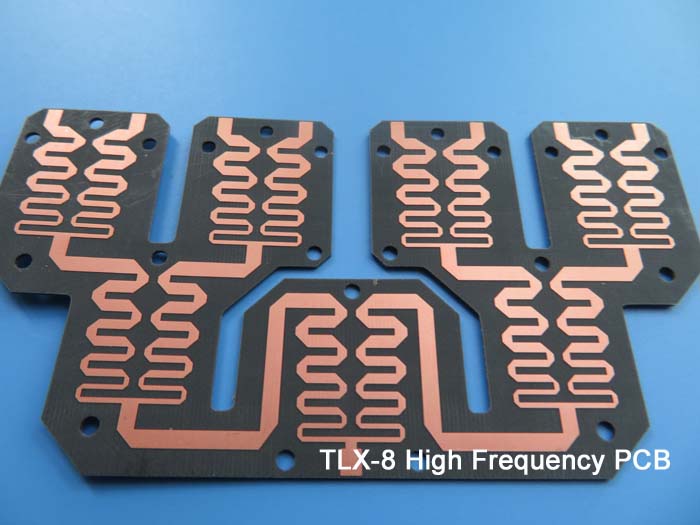

We

are thrilled to announce the global availability of 31mil TLX-8 PCB, a

PTFE fiberglass laminate renowned for its unrivaled reliability and

versatility.

Taconic TLX-8 PCB as a

game-changer in the PCB industry, offering engineers and designers an

exceptional high-volume antenna material to power their RF applications. With a

wide range of available thicknesses and copper cladding options, TLX-8 high

frequency PCB proves itself indispensable in low layer count microwave designs,

where mechanical reinforcement and superior performance in extreme environments

are paramount.

One

of the standout features of TLX-8 is its resistance to creep, making it the

optimal choice for PWBs bolted to housings that encounter intense vibrations

during space launches. This characteristic ensures reliable performance and

durability, even in the harshest conditions. TLX-8's ability to withstand high

temperatures in engine modules further solidifies its position as a material of

choice for demanding applications.

Moreover, Taconic TLX-8 substrate board exhibits excellent radiation resistance, making it a preferred solution

for space applications that require low outgassing materials. Engineers seeking

reliable materials for space projects can find valuable information on NASA's

website regarding TLX-8's compatibility with radiation-resistant applications

in outer space.

TLX-8

boasts an impressive array of benefits that set it apart from conventional

materials. It delivers excellent PIM values in PCBs, surpassing industry

standards by measuring lower than -160 dBc*. This extraordinary performance

ensures superior signal integrity and minimal interference, meeting the

demanding requirements of high-frequency RF applications.

The

exceptional mechanical and thermal properties of TLX-8 make it an ideal choice

for mission-critical applications. Its low and stable dielectric constant (Dk)

enables precise control over signal propagation, ensuring reliable and

consistent performance. With low moisture absorption, tightly controlled Dk,

and a UL 94 V0 flammability rating, Taconic TLX-8 PCB circuit guarantees outstanding performance

and safety.

TLX-8's

electrical properties are equally impressive. With a dielectric constant of

2.55 ± 0.04 at 10 GHz and a dissipation factor of 0.0018 at the same frequency,

TLX-8 guarantees exceptional electrical performance. Its surface and volume

resistivity values meet stringent industry standards, ensuring consistent

performance even under elevated temperature and humidity conditions.

To

demonstrate the versatility and compatibility of TLX-8, we are excited to

unveil our latest product: a 2-layer rigid PCB constructed using TLX-8 as the

core material. This PCB configuration features copper layers on both sides,

each with a thickness of 35 μm, while the TLX-8 core measures 0.787 mm (31

mils) in thickness. This design offers excellent RF performance and enables low

layer count microwave designs, catering to the evolving needs of the industry.

To

ensure the highest quality standards, our TLX-8-based PCBs undergo rigorous

testing in line with IPC-Class-2 standards. Each board undergoes a 100%

electrical test to verify its functionality and performance before shipment,

ensuring optimal reliability and customer satisfaction.

We

are proud to make TLX-8 and its associated PCBs available to customers

worldwide. With our unwavering commitment to delivering cutting-edge solutions

and exceptional customer service, we strive to meet the diverse needs of

engineers and designers across various industries in the ever-evolving world of

PCB manufacturing.

Environmental Sustainability:

Sustainable

practices have gained significant traction in the PCB industry. Manufacturers

are adopting eco-friendly processes, materials, and waste management techniques

to reduce their environmental footprint. This includes the use of lead-free

soldering, recyclable materials, and energy-efficient production methods.

Additionally, the industry is focusing on developing PCBs that are easier to

recycle at the end of their lifecycle, contributing to a more sustainable and

environmentally conscious manufacturing ecosystem.

Industry 4.0 and Automation:

The

PCB industry is embracing the principles of Industry 4.0, leveraging

automation, artificial intelligence (AI), machine learning (ML), and data

analytics to enhance production efficiency, quality control, and supply chain

management. Automated optical inspection (AOI), robotic assembly, and

intelligent process control systems are becoming integral parts of modern PCB

manufacturing facilities, enabling faster production cycles, improved error

detection, reduced costs, and enhanced overall productivity.

Advanced Testing and Quality Assurance:

With

the increasing complexity of PCB designs and the demand for higher reliability,

advanced testing and quality assurance methods are gaining prominence.

Manufacturers are investing in state-of-the-art testing equipment, including

automated testing systems, X-ray inspection, flying probe testing, and

in-circuit testing (ICT). These technologies ensure that PCBs meet stringent

quality standards, functional requirements, and customer specifications,

minimizing the risk of failures in the field.

The

PCB industry is at the forefront of technological innovation, driving

advancements that power the digital revolution in various sectors. It is our

responsibility to stay informed about these developments, collaborate with our

customers, and provide them with cutting-edge solutions that meet their

evolving needs. By embracing emerging technologies and fostering sustainable

practices, the PCB industry is set to shape the future of electronics and

enable transformative applications across industries worldwide.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com