Analysis of the

High-Speed PCB Industry

Introduction:

The

high-speed PCB industry plays a pivotal role in meeting the increasing demand

for electronic devices capable of handling high-frequency signals and data

transmission. This analysis provides an in-depth exploration of the high-speed

PCB industry, including its market dynamics, technological advancements,

challenges, and future prospects.

Market Dynamics

1)Growing Demand

The

demand for high-speed PCBs is driven by various factors, including the rapid

growth of technologies such as 5G wireless communication, Internet of Things

(IoT), cloud computing, artificial intelligence (AI), and autonomous vehicles.

These applications require high-performance electronic devices that can

reliably transmit and process data at high speeds.

2)Communication Infrastructure

The

deployment of 5G networks is a significant driver for the high-speed PCB

industry. The implementation of 5G requires advanced communication

infrastructure, including base stations, antennas, and network equipment, which

heavily rely on high-speed PCBs. The demand for faster data rates, reduced

latency, and increased bandwidth necessitates the use of high-speed PCBs to

ensure reliable signal integrity.

3)Automotive Electronics

The

automotive industry is another key driver of the high-speed PCB market. The

integration of electronic systems for advanced driver assistance systems

(ADAS), infotainment systems, radar systems, and electric vehicle powertrains

requires high-speed PCBs to handle the increased data processing and

communication requirements. The shift towards electric vehicles and autonomous

driving technologies further fuels the demand for high-speed PCBs in this

sector.

4)Miniaturization and High-Density Interconnects

The

continuous drive for smaller and lighter electronic devices with increased

functionality has led to the miniaturization of components and the need for

high-density interconnects. High-speed PCBs with smaller form factors,

high-density routing, and advanced technologies like microvias and high-density

interconnect (HDI) are essential to accommodate the miniaturization trend while

maintaining signal integrity and performance.

Technological Advancements

1)Advanced Materials

High-speed

PCBs require materials with excellent electrical properties, such as low

dielectric constant and low loss tangent, to minimize signal loss and maintain

signal integrity. Materials like FR-4, PTFE (Polytetrafluoroethylene), and

specialty laminates are commonly used. The development of new materials with

improved electrical characteristics is an ongoing focus in the industry.

2)Controlled Impedance and Signal Integrity

Maintaining

controlled impedance is critical in high-speed PCB design to minimize signal

reflections, crosstalk, and electromagnetic interference (EMI). Designers

employ techniques like controlled trace widths, controlled dielectric

thickness, differential signaling, and optimized ground planes to ensure signal

integrity and reduce signal degradation.

3)Simulation and Modeling Tools

Advanced

simulation and modeling tools are instrumental in high-speed PCB design. These

tools enable designers to analyze signal behavior, identify potential issues,

and optimize the layout before fabrication. Techniques such as electromagnetic

simulation, eye diagram analysis, and time-domain reflectometry (TDR) aid in

predicting and mitigating signal integrity issues.

4)Design for Manufacturability (DFM)

Designing

high-speed PCBs requires consideration of manufacturing processes and

constraints. Collaborative efforts between design engineers and PCB

manufacturers are crucial to ensure manufacturability, optimize signal routing,

and address potential fabrication challenges. Design for Manufacturability

(DFM) guidelines and practices are employed to enhance yield and reduce

manufacturing costs.

Challenges and Considerations

1)Signal Integrity and EMI

High-speed

PCB design presents challenges related to signal integrity, including impedance

matching, signal reflections, crosstalk, and electromagnetic interference

(EMI). Designers must carefully manage trace lengths, control impedance, and

employ shielding techniques to mitigate these challenges and maintain signal

integrity.

2)Thermal Management

High-speed

electronic devices generate heat, which can impact signal integrity and

reliability. Effective thermal management techniques, such as proper heat

sinking, thermal vias, and appropriate board layouts, are essential to

dissipate heat and prevent thermal-induced issues.

3)Design Constraints

High-speed

PCB design requires careful consideration of design constraints, such as

controlled impedance, tight tolerances, and design rules specific to high-speed

applications. Compliance with industry standards and design guidelines, such as

those provided by the Institute of Electrical and Electronics Engineers (IEEE)

and the IPC (Association Connecting Electronics Industries), is necessary to

ensure interoperability and compatibility.

Future Prospects

1)Emerging Technologies

The

high-speed PCB industry is expected to benefit from emerging technologies like

5G, mmWave communication, and optical interconnects. These technologies will

drive the need for even higher data rates, improved signal integrity, and

advanced PCB designs capable of handling the increasing demands of future

applications.

2)Industry Collaboration and Expertise

Collaboration

between PCB manufacturers, design engineers, and semiconductor companies will

be crucial for addressing the evolving challenges of high-speed PCB design.

Expertise in high-speed design, signal integrity analysis, and manufacturing

processes will continue to be vital to meet the stringent requirements of

high-speed applications.

3)Advances in Materials and Manufacturing

Ongoing

advancements in materials, fabrication techniques, and design methodologies

will further enhance the capabilities of high-speed PCBs. The development of

new materials with improved electrical properties, advanced fabrication

techniques like additive manufacturing, and innovative design methodologies

will contribute to the continued evolution of the high-speed PCB industry.

4)Increased Focus on Signal Integrity

As

data rates and frequencies continue to rise, ensuring robust signal integrity

will remain a critical concern in high-speed PCB design. Designers will need to

adopt advanced simulation tools, modeling techniques, and signal integrity

analysis methodologies to optimize signal performance and minimize noise and

interference.

5)Sustainability and Environmental Considerations

Like

the broader electronics industry, the high-speed PCB industry is likely to face

increasing pressure to adopt sustainable practices. This includes using

eco-friendly materials, minimizing waste, and implementing recycling

initiatives to reduce the environmental impact of PCB manufacturing processes.

Conclusion:

The

high-speed PCB industry is driven by the growing demand for high-performance

electronic devices capable of handling high-frequency signals and data

transmission. With the deployment of 5G networks, advancements in automotive

electronics, and the ongoing trend towards miniaturization, the demand for

high-speed PCBs is expected to continue to rise.

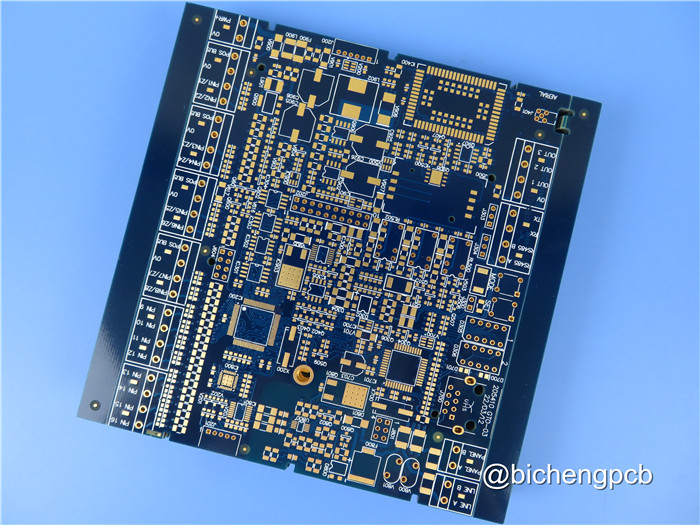

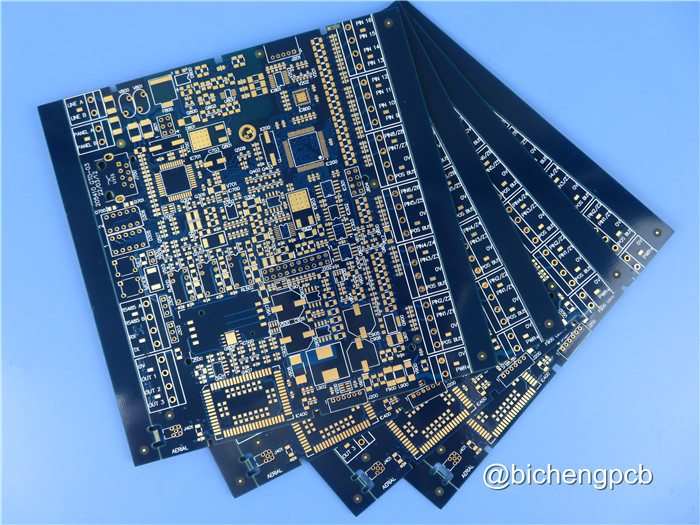

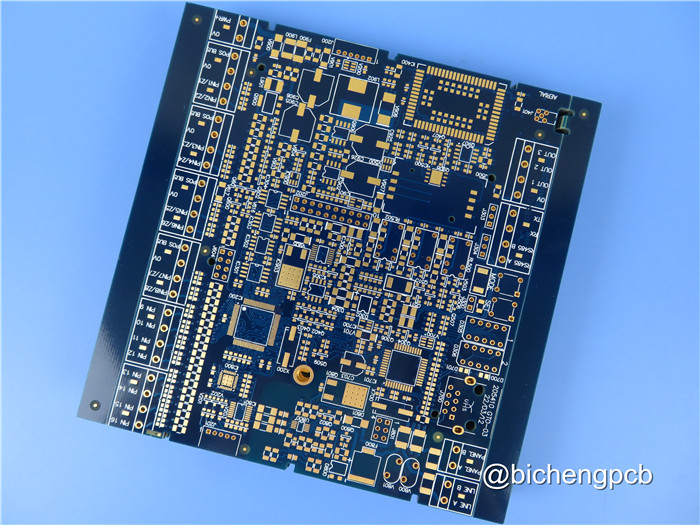

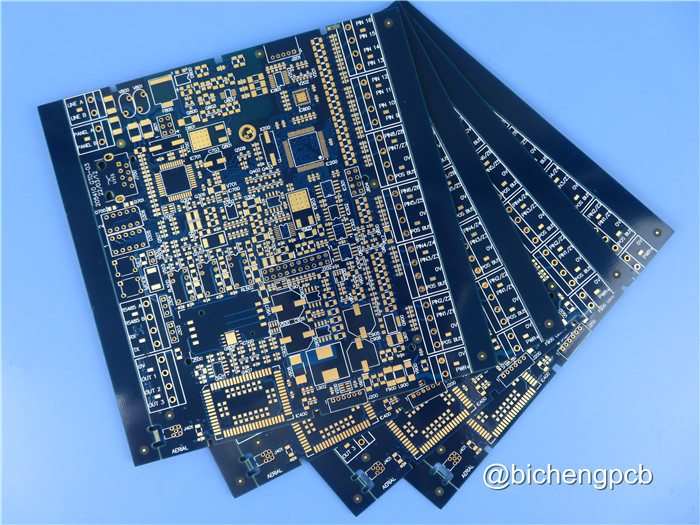

Technological

advancements in materials, simulation tools, and manufacturing processes will

enable the development of high-speed PCBs with improved signal integrity,

reduced signal loss, and increased reliability. However, challenges related to

signal integrity, thermal management, and design constraints must be carefully

addressed to ensure optimal performance, such as M6 high speed PCB.

Collaboration

between industry stakeholders and the adoption of best practices, such as

design for manufacturability and compliance with industry standards, will be

essential for driving innovation and meeting the evolving needs of high-speed

applications.

Looking

ahead, emerging technologies, industry collaboration, and sustainability

considerations will shape the future of the high-speed PCB industry as it

continues to play a critical role in enabling the next generation of

high-performance electronic devices.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com