Advancements in High-Frequency PCBs Drive Innovation in the Electronics Industry

Introduction:

The rapid evolution of technology has led to increased demand for high-frequency printed circuit boards (PCBs) in various applications such as telecommunications, aerospace, defense, and wireless communication systems. High-frequency PCBs play a crucial role in enabling the transmission of high-speed and high-frequency signals with minimal losses. In recent years, significant advancements in high-frequency PCB manufacturing techniques, materials, and design practices have been driving innovation and pushing the boundaries of what is possible in the electronics industry.

Material Innovations:

One of the key factors influencing the performance of high-frequency PCBs is the choice of materials. Traditional PCB materials such as FR-4 have limitations when it comes to high-frequency applications due to their relatively high dielectric constant and loss tangent. To overcome these limitations, new materials with improved electrical properties have been developed. For instance, specialized materials like Rogers material, Teflon, and polyimide offer low dielectric loss, low moisture absorption, and excellent dimensional stability, making them ideal choices for high-frequency PCBs.

Design Techniques:

Designing a high-frequency PCB requires careful consideration of various factors such as trace widths, spacing, and impedance matching. Advances in design software and simulation tools have made it easier for engineers to optimize their high-frequency PCB designs. With the help of electromagnetic simulation software, designers can predict and mitigate signal integrity issues, reduce electromagnetic interference (EMI), and optimize the performance of their high-frequency circuits. Techniques like controlled impedance routing, differential signaling, and microstrip/stripline configurations are commonly employed to achieve high-frequency performance.

Miniaturization and Integration:

The demand for smaller and more compact electronic devices has driven the need for miniaturization and integration of components. High-frequency PCBs have played a significant role in enabling this trend. With advancements in manufacturing processes, it is now possible to print finer lines and spaces, allowing for denser component placement and reduced signal propagation lengths. This, in turn, leads to improved signal integrity, reduced EMI, and increased overall performance of high-frequency circuits.

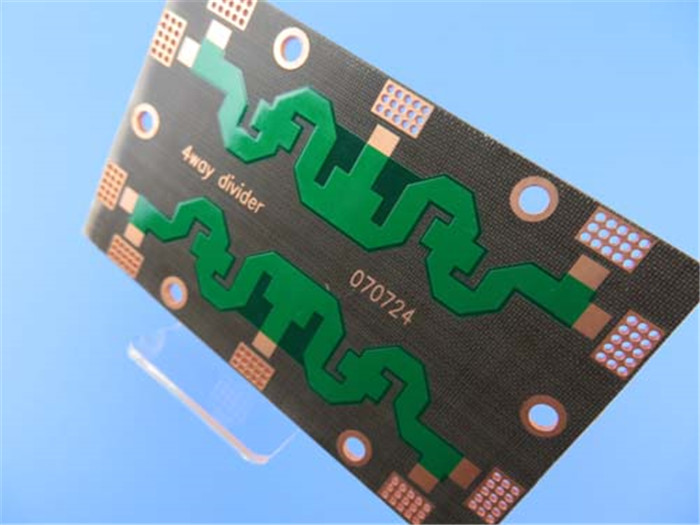

RF and Microwave Applications:

High-frequency PCBs find extensive use in RF and microwave applications, where the ability to transmit and receive signals accurately at high frequencies is critical. These PCBs are used in radar systems, satellite communication, wireless networks, and cellular base stations, among other applications. The advancements in high-frequency PCB technology have enabled the development of advanced RF and microwave systems with enhanced performance, improved signal quality, and higher data rates.

Automotive Industry:

The automotive industry is another sector that has greatly benefited from the advancements in high-frequency PCBs. With the rise of electric and autonomous vehicles, the demand for high-frequency communication systems has grown. High-frequency PCBs are an integral part of these systems, enabling functions such as collision detection, advanced driver-assistance systems (ADAS), vehicle-to-vehicle communication, and infotainment systems. The ability of high-frequency PCBs to transmit large amounts of data quickly and reliably is crucial for the safe and efficient operation of modern vehicles.

Conclusion:

The continuous advancements in high-frequency PCB technology have revolutionized the electronics industry, enabling the development of cutting-edge devices and systems. From aerospace to telecommunications and automotive applications, high-frequency PCBs are crucial for achieving high-speed, high-frequency signal transmission with minimal losses. Material innovations, design techniques, miniaturization, and integration have collectively contributed to improved performance, reduced EMI, and increased functionality in high-frequency PCBs. As technology continues to evolve, we can expect further innovations in high-frequency PCBs, paving the way for even more advanced and sophisticated electronics in future.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com