High-Frequency PCB Industry Sees Explosive Growth Driven by 5G and Satellite Internet

The global digital transformation is accelerating, and high-frequency printed circuit boards (PCBs), serving as the core carriers for wireless communication, high-speed transmission, and signal processing, have become one of the most dynamic growth areas in the electronics information industry. With the comprehensive commercialization of 5G, large-scale deployment of low-earth orbit (LEO) satellite internet constellations, and the proliferation of automotive millimeter-wave radar, the demand for high-frequency, low-loss, and high-reliability PCBs is growing exponentially. This trend is also driving rapid iterations in upstream materials, processes, and manufacturing technologies.

5G-Advanced and 6G R&D Drive Upgrades in High-Frequency Materials

The construction of 5G networks is transitioning from widespread coverage to precise optimization and performance enhancement. 5G-Advanced technology is further upgrading base station antennas and radio frequency front-ends. The continuous increase in Massive MIMO antenna channels demands higher integration, better heat dissipation, and improved signal integrity from base station PCBs. Meanwhile, 6G research and development has commenced globally, with the terahertz (THz) frequency band becoming a key focus. This implies thathigh-frequency PCBsmust evolve toward higher frequency bands and lower transmission losses.

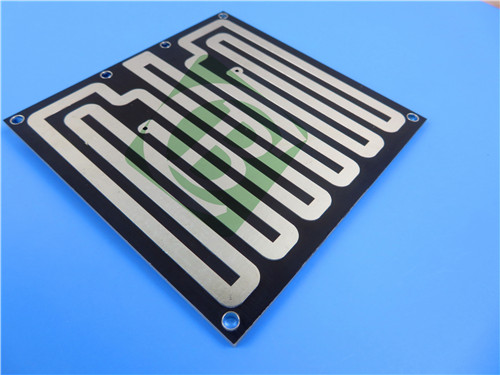

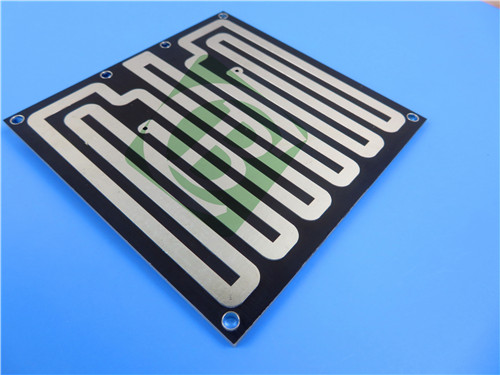

In response to this trend, traditional hydrocarbon and PTFE (polytetrafluoroethylene) substrates can no longer fully meet future requirements. Ceramic-filled modified PTFE composite materials, with their adjustable dielectric properties, stable temperature coefficients, and excellent high-frequency characteristics, are gradually becoming the industry’s mainstream choice. For example, the F4BTME series high-frequency laminates achieve a stable dielectric constant (Dk) of 3.2±0.06 and a loss factor (Df) as low as 0.002 at 10GHz through a scientific formulation of nano-ceramic fillers and PTFE. Its Z-axis coefficient of thermal expansion (CTE) is as low as 58 ppm/°C, significantly improving the reliability of metallized hole interconnections, making it highly suitable for high-frequency multilayer board structures.

LEO Satellite Constellation Development Fuels Demand for Aerospace-Grade High-Frequency PCBs

Companies such as SpaceX, OneWeb, and China SatNet are fiercely competing in the LEO satellite internet sector. Plans to manufacture tens of thousands of satellites are creating a massive incremental market for high-frequency PCBs. Satellite communication payloads and phased array antennas need to operate in high-frequency bands such as Ka and Ku, requiring PCB materials with extremely low loss, excellent passive intermodulation (PIM) performance, and resistance to radiation and extreme temperature variations.

For aerospace applications, high-frequency PCB materials must maintain performance stability in vacuum environments, suppress outgassing, and withstand intense vibrations during launch. Materials such as ceramic-reinforced PTFE substrates likeF4BTME, with a PIM rating below -160 dBc, a temperature coefficient of dielectric constant as low as -75 ppm/°C, and a low moisture absorption rate of 0.05%, have become the ideal choice for onboard communication equipment, feed networks, and beamforming antennas. These properties ensure long-term stable signal transmission in complex space environments.

Proliferation of Automotive Millimeter-Wave Radar Drives Demand for High-Frequency PCBs

As the level of autonomous driving increases, automotive millimeter-wave radar is penetrating from high-end vehicles to mainstream models. It is expected that 77GHz radar will become the standard for future ADAS systems. The shorter wavelength of 77GHz radar imposes strict requirements on PCB precision and material consistency, as even minor dielectric fluctuations can affect detection accuracy.

This poses challenges for PCB processing: dielectric layer thickness uniformity must be controlled, copper foil surface roughness consistency must be maintained, and finer line width and spacing designs must be adopted. Materials that offer stable Dk/Df values, low copper loss, and good thermal management performance—such as PTFE-based materials with specific ceramic filling systems—are critical for achieving high-yield automotive radar PCB manufacturing. These materials exhibit stable electrical performance within a temperature range of -55°C to 150°C, ensuring radar reliability in extreme weather conditions.

Technical Challenges and Industry Collaboration Key to Breakthroughs

Despite the broad market prospects, large-scale manufacturing of high-frequency PCBs still faces several technical bottlenecks: processability of high-frequency materials (e.g., hole metallization bonding strength), stability of multilayer board lamination processes, and cost control issues require collaborative efforts across the industry chain.

PCB manufacturers are closely collaborating with material suppliers such as Panasonic, Rogers, and Shengyi Technology to develop more cost-effective ceramic-based PTFE hybrid dielectric materials. Meanwhile, to enhance product consistency, the adoption of laser direct imaging (LDI), plasma processing systems, and automated optical inspection (AOI) has become standard in high-frequency PCB production lines.

Conclusion: New Materials and Applications Shape the Industry’s Future

High-frequency PCBs have entered a critical phase where technology drives application. 5G/6G communication, satellite internet, and autonomous driving are not only current hotspots but also core engines for industry growth over the next decade. The ability to master the process adaptability of advanced high-frequency materials and improve the design and manufacturing capabilities of multilayer high-precision circuits will be decisive for companies seeking to win in the next-generation communication and smart device markets. In this round of industry upgrading, material platforms that combine high performance, high reliability, and excellent processability will become important pillars of innovation for the entire electronics industry.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com