Rogers RO3003 PCB: Everything You Needed to Know

Rogers RO3003 is a

high-frequency PCB material known for its excellent electrical properties, low loss, and high thermal conductivity. It is widely used in applications such as wireless communication systems, radar systems, satellite systems, and high-speed digital circuits.

One of the significant benefits of RO3003 is its low dielectric loss, making it ideal for high-frequency applications. It also has a low dissipation factor, high thermal conductivity, and excellent dimensional stability. The material's high glass transition temperature (Tg) also ensures its stability in high-temperature environments.

Rogers RO3003 PCB board has a dielectric constant of 3.0 and a loss tangent of 0.0013 at 10 GHz, which is lower than other high-frequency PCB materials. It also has a low moisture absorption rate and excellent electrical and mechanical properties over a wide temperature range, from -55°C to 150°C.

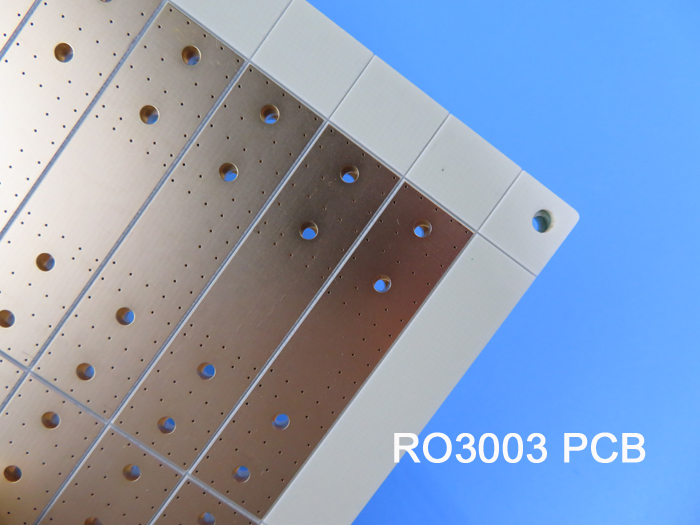

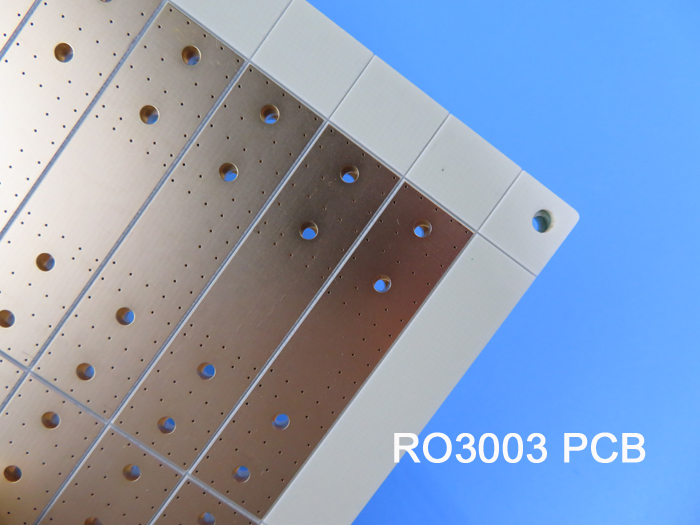

There is a 60mil Rogers RO3003 PCB for reference.

The material's excellent properties make it an ideal choice for applications that require high-frequency performance and reliability, such as high-speed digital circuits, microwave devices, power amplifiers, and antennas.

This material has several characteristics that make it suitable for high-frequency applications.

One of the key parameters of RO3003 is its dielectric constant. The dielectric constant of RO3003 is typically 3.0, with a tolerance of ±0.04. This property is measured using the IPC-TM-650 2.5.5.5 Clamped Stripline method at 10 GHz and 23℃. The dielectric constant is also measured using the Differential Phase Length method over a frequency range of 8GHz to 40 GHz.

The dissipation factor of RO3003 is typically 0.001 at 10 GHz and 23℃, as per the IPC-TM-650 2.5.5.5 test method. This parameter is an indicator of the energy loss in the dielectric material of the PCB. RO3003 has a low dissipation factor, which makes it ideal for high-frequency applications.

Another important property of RO3003 is its thermal coefficient of ε, which is -3 ppm/℃ at 10 GHz and over a temperature range of -50℃ to 150℃. This parameter indicates the change in dielectric constant with temperature. A low thermal coefficient of ε means that the material is stable over a wide temperature range.

RO3003 has good dimensional stability, with a value of 0.06-0.07 mm/m in the X and Y directions, as per IPC-TM-650 2.2.4 under Condition A. This means that the material is less likely to warp or deform during the manufacturing process.

The volume resistivity and surface resistivity of RO3003 are both 107 MΩ.cm and 107 MΩ respectively, under Condition A as per IPC 2.5.17.1. These parameters indicate the material's ability to resist the flow of electric current.

RO3003 has a high tensile modulus of 930 MPa in the X direction and 823 MPa in the Y direction at 23℃, as per ASTM D 638. This means that it has high strength and stiffness.

The material has a low moisture absorption rate of 0.04%, as per IPC-TM-650 2.6.2.1 D48/50. This property ensures that the material maintains its properties even in humid conditions.

RO3003 has a specific heat of 0.9 j/g/k, which is a measure of the material's ability to store heat. The thermal conductivity of RO3003 is 0.5 W/M/K at 50℃, as per ASTM D 5470. This parameter indicates the material's ability to conduct heat.

The coefficient of thermal expansion of RO3003 ranges from 16 to 25 ppm/℃ in the X and Y directions, and 17 ppm/℃ in the Z direction, at 23℃/50% RH, as per IPC-TM-650 2.4.4.1. This property indicates the material's ability to expand and contract with temperature changes.

RO3003 has a high temperature resistance, with a Td (decomposition temperature) of 500℃ as per ASTM D 3850. This property ensures that the material can withstand high-temperature applications.

The material has a density of 2.1 gm/cm3 at 23℃, as per ASTM D 792. This property indicates the weight of the material.

RO3003 has good copper peel strength of 12.7 Ib/in. with 1oz copper and after solder float, as per IPC-TM 2.4.

Bicheng PCB has extensive experience in manufacturing RO3003 PCBs and offers Design for Manufacturing (DFM) services to ensure the highest quality products. Their DFM capabilities include analyzing the design's manufacturability, optimizing the design for fabrication, and identifying potential issues that may affect the PCB's performance.

Bicheng PCB's DFM services also include analyzing the board's layer stackup, trace width, spacing, and via placement, ensuring that the board meets the customer's requirements and specifications. Their team of experts can provide design recommendations and modifications to optimize the board's performance and ensure its manufacturability.

In summary,

Rogers RO3003 PCB is an excellent choice for high-frequency applications that require low loss, high thermal conductivity, and excellent electrical properties. Bicheng PCB's DFM capabilities ensure that the PCB is manufactured to the highest standards and meets the customer's specifications, making them an ideal partner for RO3003 PCB manufacturing.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com