The penetration rate of Mini-LEDs continues to increase, placing higher demands on PCBs

1. Mini-LED has excellent performance and broad market scale

The overall performance of Mini-LED is excellent, and the backlight market is the first to open a breakthrough. Generally speaking, Mini-LED 100-300μm LED chips, chip spacing between 0.1-1mm, using SMD, COB or IMD package form of micro LED device modules, are often used in RGB display or LCD backlight, current backlight solutions As the mainstream solution in the market, Zhixian's penetration rate is still low. Mini-LED inherits the high efficiency, high brightness, high reliability and fast response time of inorganic LEDs. Compared with traditional backlight design, Mini-LED has better brightness uniformity and higher contrast. Compared with OLED, Mini-LED has the advantages of longer life and higher brightness. At the same time, Mini-LED has obvious price advantages, especially 8K and super large size (75 inches and above).

The Mini-LED market is developing rapidly, and the market size is expected to exceed US$2 billion. Apple's new iPad pro launched at the April 2021 conference is equipped with a Mini-LED screen, uses more than 10,000 lamp beads, and more than 2,500 local dimming zones. Samsung also launched TVs equipped with Mini-LED screens in China in March. Under the leadership of Apple and Samsung, major manufacturers have suit, and the Mini-LED market has rapidly expanded. According to Arizton's prediction, the global Mini LED market size is expected to increase from US$150 million to US$2.32 billion from 2021 to 2024, with a compound annual growth rate of up to 149%. The Mini-LED market is the first to explode in the large-size field. With the gradual decline in cost, Mini-LED will accelerate the penetration of medium-size, and the market size will further increase.

2. Mini-LED puts forward higher requirements on the backplane, and the current PCB is the mainstream solution

Mini-LEDs have higher requirements on the substrate due to the reduction of chip size and pitch. Mini-LED substrate solutions currently mainly include PCB, FPC and glass, among which PCB and glass substrates are more popular. The difference between PCB substrate and glass substrate is mainly reflected in the following aspects: The cost of PCB materials is significantly higher than that of glass materials. Due to the complex process of glass substrates and high overall costs, glass substrates will still be subject to low yield and large-scale in the short term. The degree is not high. The PCB substrate has high structural strength and relatively mature technology, but the process accuracy is low, the glass substrate has high thermal conductivity and other properties, and the cost is low, but the substrate process is immature and easy to break. Under the current technological conditions, the PCB solution is the mainstream solution for Mini-LED substrates.

The area of the LED chip is reduced, and the spacing is reduced, and the requirements for PCB manufacturing are getting higher and higher. Common substrates are PCB, FPC and BT-FPC. PCB made of flame-retardant 4 (FR-4) material is the most widely used material among LED materials for LCD backlights. With the substantial increase in the luminous efficiency of LEDs, FR-4 PCBs have gradually replaced metal PCBs. At present, Mini-LEDs FR-4 is commonly used as a backlight. In order to reduce the thickness of the backlight, some manufacturers have also introduced FPC and BT-FPC solutions. With the size and spacing of the chips, the requirements for the PCB board are different. The smaller the spacing, the higher the performance requirements of the PCB. At present, the commonly used PCB substrates are generally 6-layer 2-stage and 8-layer 3-stage. In the future, as the distance between Mini-LEDs is further reduced, the requirements for PCB boards will be higher. (Report source: Future Think Tank)

Mini-LED penetration and rapid growth of the PCB market

TV manufacturers are actively launching Mini-LED products, and large-size fields are gradually replacing OLED. In the field of large sizes, the cost of Mini-LEDs is lower than that of OLED screens. When the display effect is comparable to that of OLEDs, Mini-LEDs also have a longer service life. Since 2021, Samsung, Skyworth, LG, TCL, Konka and other manufacturers have released TVs equipped with Mini-LED technology. In the field of high-end large-screen TVs, the replacement of OLED TVs has begun. With the continuous upgrading of Mini-LED technology and the improvement of yield rate, the cost of Mini-LED will be further reduced and will gradually penetrate the mid-to-high-end TV field. According to our research, the cost price of a 65-inch Mini-LED TV panel in 2019 will be around US$700, and the cost in 2021 has dropped to around US$300-400. At present, TV manufacturers are actively promoting Mini-LED TVs. According to the online data of 618 this year, Mini-LED TVs accounted for 0.2%, OLEDs accounted for 0.4%, and Mini-LED TVs have a tendency to surpass OLEDs. According to Luotu Technology's forecast, the market sales of Mini-LED TVs in 2021 will be 3 million units, and this number will reach 18 million units in 2025, and the CAGR for 2021-2025 will be as high as 56.5%.

The medium-size market is expected to gradually penetrate, and the small-size market is difficult to start in the short term. According to Nikkei News and Fomalhaut Techno, the cost of Apple's iPad Pro in 2021 is estimated to be US$510, which is 30% higher than the previous generation. The cost of Mini-LED backlight module is estimated to be US$90, which is still at a relatively high level. However, due to the advantages of high image quality and low power consumption, the performance is still better than that of OLED. In the future, as the cost further drops, the penetration rate of the mid-size market will further increase. In the field of small size, due to the needs of fingerprint recognition, folding screens and thinness under the screen of mobile phones, it is difficult for Mini-LED to penetrate in the field of small size in the short term, and OLED will still be the mainstream high-end mobile phone screen.

The supply chain gradually matures, and the TV, laptop, and tablet sectors will become the main downstream applications of Mini-LED, and the PCB substrate market may reach 10 billion yuan. At present, the domestic Mini-LED supply chain is basically mature, and manufacturing costs are also significantly reduced. Mini-LED backlight displays are showing explosive growth. CINNO Research predicts that by 2025, the annual shipments of Mini LED backlight modules will reach about 170 million, of which small and medium-sized consumer applications such as displays, notebooks, and tablets will account for about 65%, and the substrate area will reach about 41 million. ㎡, 75% of which are TV backlight substrates. According to our research, the price of a single-chip Mini-LED PCB substrate is about US$20. In 2025, the market size of Mini-LED PCB will be close to 20 billion yuan. Considering the future price drop, the market of Mini-LED PCB substrate It will still be close to 10 billion yuan.

Domestic PCB-related manufacturers have advanced layout and usher in a new wave of development opportunities

The large-scale commercial use of Mini-LEDs has benefited PCB manufacturers significantly. PCB substrates account for the largest proportion of the cost of Mini-LED backlight modules. According to our estimation, it is about 40%. The threshold of Mini-LED PCB is mainly reflected in the large-scale mass production capacity and yield. Many domestic manufacturers have developed Mini-LED PCB substrates. We believe that rapid mass production capacity and improved yield are the current competitive standards for measuring PCB manufacturers. With the increase in the level of PCB mass production and the increase in yield, the production cost of Mini-LED PCB substrates has a large room for reduction, and the decrease in PCB cost will promote the increase in the penetration rate of Mini-LED. It is expected to form a virtuous circle.

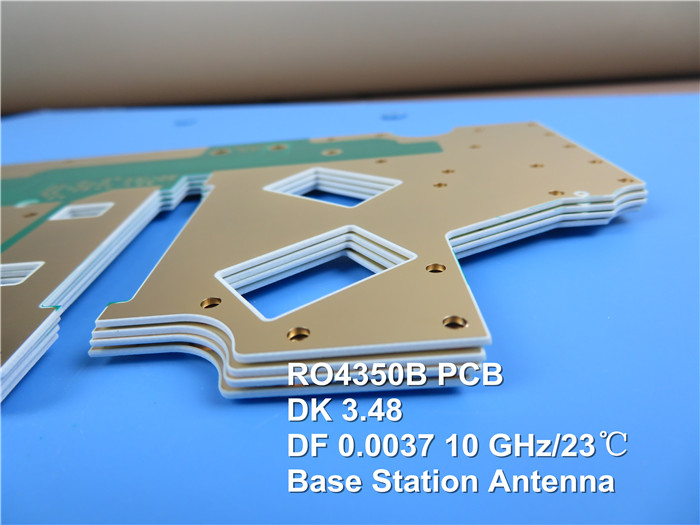

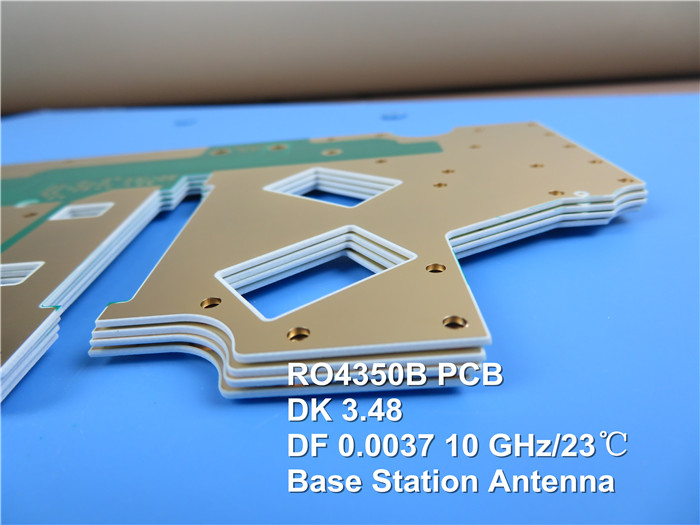

picture

PCB manufacturers increase investment in Mini-LED substrates, and domestic manufacturers are ushering in opportunities. From a global perspective, there are currently many manufacturers that have developed Mini-LED PCB substrates, including Taiwanese companies Xinxing, Trident, Tongtai, South Korea Yongfeng, mainland companies Pengding Holdings, Zhongjing Electronics, Shenghong Technology, Aoshikang et al. Fast market response capabilities, large-scale mass production capabilities, and product yield have become the core competitiveness of various manufacturers. The domestic Mini-LED industry chain is relatively mature. From the chip end to the package and display end, the country has basically achieved a complete Mini-LED industry chain, which brings opportunities for the development of domestic PCB manufacturers.

Pengding Holdings began to increase the volume of ultra-thin HDI for Mini-LED, and its supply capacity is leading in the world. The company’s initial investment in the construction of two production lines have already been mass-produced, and major customer A has successively launched mini-led iPadPro and mini-led MacBook Pro. In the first half of the year, the profitability has not been reflected due to the increase in production capacity and yield. The yield rate has been greatly improved, and the profitability has been greatly improved. At the same time, the company will continue to increase the size of mini-led boards and continue to expand the third production line on the basis of the existing monthly production capacity of 90,000 square meters.

Mini-LED penetration rate increase + domestic industrial chain support, domestic PCB manufacturers have a lot to do. We believe that under the current background of accelerated penetration of Mini-LEDs, the yield and scale of glass substrates are still far behind that of PCBs, and PCBs will be the main stream choice for Mini-LED backplanes in the short term. The domestic Mini-LED industry chain has complete upstream and downstream supporting facilities, and the industry chain has achieved independent controllability. With the continuous improvement of domestic PCB manufacturers' yield rate and declining costs, domestic Mini-LED manufacturers will give priority to domestic PCB companies as suppliers. At the same time, after recent years of industrial transfer, my country is the world's largest producer of PCBs. As domestic manufacturers continue to increase the penetration rate of Mini-LEDs, domestic manufacturers will usher in a new wave of development opportunities.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com