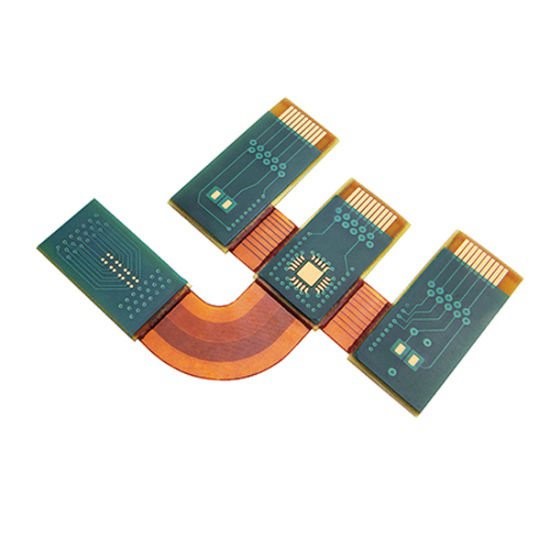

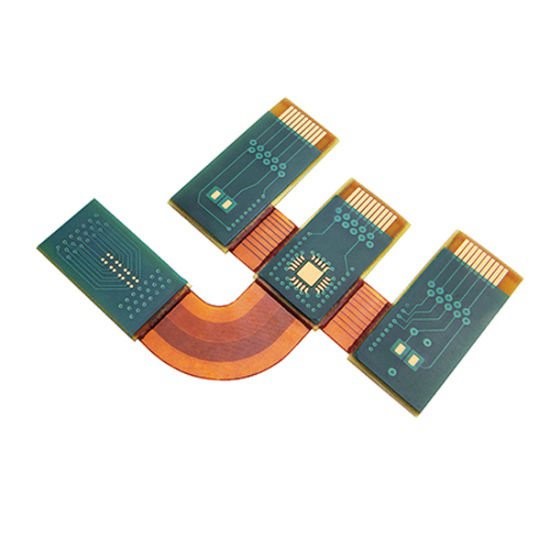

What is a flexible PCB material?

The Flex PCB board usually

consists of the following five parts.

1.Insulating Substrate

The insulating substrate is a flexible

insulating film. As the insulating carrier of the circuit board, selecting a

flexible dielectric film requires a comprehensive review of the material's heat

resistance, shape-forming properties, thickness, mechanical properties, and

electrical properties. Now flex PCB is commonly used

-

PI: Polyimide, Kapton.

-

PET: PolyeSTer, Mylar.

-

PTFE: Polytetrafluoroethylene

Generally, the thickness of the film is

selected in the range of O.0127 to O.127 mm (0.5 to 5 mil).

2.Adhesive Sheet

The function of the adhesive sheet is to

bond the film and the metal foil, or the adhesive film and the film (the cover

film). Different types of adhesive sheets can be used for different film

substrates, such as polyester adhesive sheets and polyimide adhesive sheets.

Polyimide substrate adhesive sheets are divided into epoxy and acrylic. The

choice of bonding sheet mainly examines the fluidity of the material and its

thermal expansion coefficient. There is also polyimide copper-clad sheets

without adhesive sheets, which have better chemical resistance and electrical

properties.

Due to the low glass transition temperature

of the acrylic adhesive sheet, a large amount of contamination generated during

the drilling process is not easy to remove, which affects the quality of

metalized holes and other unsatisfactory materials. Therefore, the interlayer

adhesion of multilayer flexible circuits The common polyimide material of the

sheet, because it is matched with the polyimide substrate, have the same CTE

(coefficient of thermal expansion), which overcomes the problem of dimensional

instability in multilayer flexible circuits, and other properties are

satisfactory.

3.Copper Foil

The copper foil is a conductive layer

covered on an insulating base material, and a conductive circuit is formed

after selective etching. Most of such copper foils are rolled copper foil

(Rolled Copper Foil) or electrolytic copper foil (Electrodeposited Copper

Foil).

The ductility and bending resistance of

rolled copper foil are better than that of electrolytic copper foil.

According to coating online understanding,

the elongation of rolled copper foil is 20% to 45%, and the elongation of

electrolytic copper foil is 4% to 40%. The thickness of the copper foil is most

commonly 35um (1oz), there are 18um (O.5oz) thin or 70um (2oz) thick, and even

105um (30z). Electrolytic copper foil is formed by electroplating.

The crystal state of the copper particles

is vertical needle shape, which is easy to form vertical line edges during

etching, which is beneficial to the production of precision circuits. But when

the bending radius is less than 5mm or the dynamic bending, the needle-like

structure is prone to fracture.

Therefore, most of the flexible circuit substrates are rolled copper foil, whose copper particles have

a horizontal axis structure, which can adapt to multiple windings.

4.Overlay

The cover layer is an insulating protection

layer covering the surface of the flexible printed circuit board and plays a

role in protecting the surface wires and increasing the strength of the

substrate. There are generally two types of protective materials for the outer

graphics.

-

The first type is a dry film type (cover film). Polyimide material

is used, which is laminated directly to the circuit board to be protected

after etching without an adhesive. This cover film is required to be

pre-formed before pressing to expose the parts to be welded, so it cannot

meet the requirements of finer assembly.

-

The second type is the photosensitive development type. The

first type of photosensitive development is to solve the problem of

high-density assembly by exposing the welded parts through photosensitive

development after laminating the dry film with a laminator. The second

type is a liquid screen printing type covering material. Commonly used are

Thermosetting polyimide materials, and solder resist inks for

photosensitive development type flexible circuit boards.

This type of material can better meet the

requirements of flexible boards with fine pitch and high-density assembly.

5.Flex Stiffener

The reinforcing plate is bonded to the

local plate of the flexible plate, which strengthens the flexible film

substrate to support it and facilitates the connection, fixing or other

functions of the printed circuit board. The material of the reinforcing plate

is selected according to different uses. Commonly used are polyester, polyimide

sheet, epoxy glass fiber cloth board, phenolic paper board, steel plate, aluminum

plate, etc.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com