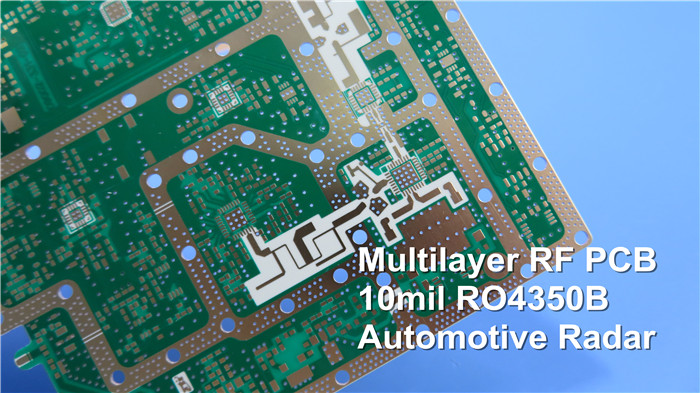

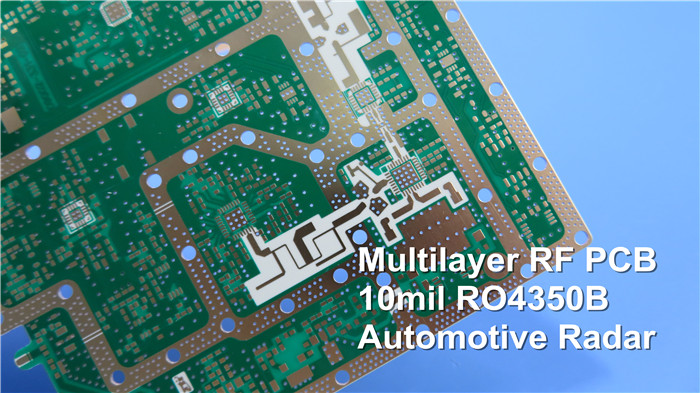

What is Rogers PCB?

Rogers PCB is a type of high-frequency board that raw material is produced by Rogers company. Epoxy resin distinguishes it from traditional PCB boards (FR4). It uses a ceramic base as the high-frequency material and lacks a glass fiber in the middle. The thermal stability and dielectric constant of Rogers are superior. It can be utilized to address the shortcomings of

PTFE substrates since copper foil and its dielectric constant thermal expansion coefficient have very similar properties. It is excellent for commercial microwave, radio frequency, and high-speed electronic design applications. Due to its low water absorption, it is perfect for high-humidity applications, giving clients in the

high-frequency board sector access to the best raw materials and resources that fundamentally improve the quality of the finished product.

Once they are aware of FR4's subpar performance at microwave frequencies, many PCB designers see Rogers as a need for high-frequency PCB materials.

PCBs using the

Rogers laminates are called

Rogers PCB.

A company called Rogers creates laminate materials that are utilized to create PCBs. PCBs are often constructed using the FR4 material, which is a glass fiber and epoxy resin hybrid. The

FR4 laminates that Rogers supplies have stronger high-frequency characteristics. The primary materials they offer have high-frequency characteristics similar to Teflon.

Rogers offers a wide variety of materials used for high-frequency PCBs with a relative permittivity ranging from 2.3 to 10.2 and low dielectric losses:

-

Fluoroplastics RT/duroid series (RT500, RT600);

-

Reinforced fluoroplastics RO3000 and RO4000 series;

-

Hydrocarbon ceramics TMM;

-

Reinforced laminates ULTRALAM 2000.

All materials have a standard range of thicknesses and can have one- or two-sided metallization from electrodeposited or rolled foil (copper, brass, aluminum) of a given thickness.

Rogers materials can be combined with FR4 to create printed circuit boards because they both have high properties (loss tangent, dielectric constant, etc.).

The following beneficial qualities are offered by Rogers PCBs:

-

Throughout the performance, they have the least amount of electrical signal loss.

-

They also have the lowest dielectric losses.

-

They offer efficient thermal function management.

-

They have a wide variety of dielectric constant values.

-

They offer the minimal outgassing capability, which is crucial for applications in space.

-

Additionally, they feature effective impedance control.

The ceramic hydrocarbon lamination of the Rogers PCBs is combined with an insulating dielectric layer. For electrical connections and changes, this layer functions as a poor conductor. In this case, good insulating materials include the oxides of metals and other substances like mica and porcelain. The special qualities of the insulating substance are enhanced by this use.

This insulating layer significantly lowers the loss of signals on PCBs. Additionally, it aids in preserving the dielectric constant within a specific range. Rogers PCBs can therefore be used in a variety of disciplines and industries. They offer crucial and distinctive qualities, performing best at high frequencies.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com