Advanced High-Frequency PCBs: Paving the Way for Future Applications

The high-frequency PCB market in 2025 is a hotbed of activity, with trends and opportunities emerging at a breakneck pace. Recent market research indicates a staggering 30% year-on-year growth, driven by a confluence of factors.

One of the most significant drivers is the automotive industry's shift towards electrification and autonomous driving. High-frequency PCBs are now integral to advanced driver-assistance systems (ADAS), with radar and sensor modules relying on their precision signal handling. A case in point is the new breed of electric vehicles that use high-frequency PCBs to manage battery management systems more efficiently, optimizing charging times and extending range.

In parallel, the consumer electronics sector continues to fuel demand. Smartphones, tablets, and gaming consoles are constantly evolving, demanding higher frequencies and faster data transfer rates. Manufacturers are scrambling to meet this need, and our Bicheng company has positioned itself strategically.

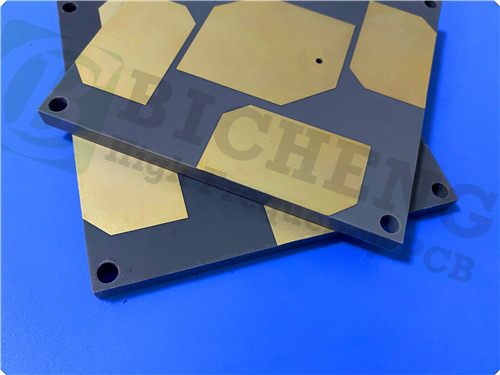

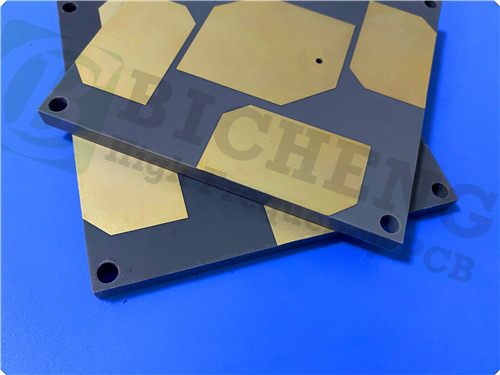

We are proud to announce our newly shipped PCB, the F4BTMS series. It is an upgraded version of the F4BTM series and has achieved remarkable technological breakthroughs. The material is enhanced with a significant amount of ceramics and reinforced with ultra-thin and ultra-fine glass fiber cloth. This results in outstanding material performance and a broader range of dielectric constants, making it highly reliable and suitable for aerospace applications, capable of replacing similar foreign products.

By cleverly incorporating a small amount of ultra-thin and ultra-fine glass fiber cloth and a large amount of uniformly distributed special nano-ceramics mixed with polytetrafluoroethylene resin, we have minimized the negative effects of glass fiber on electromagnetic wave propagation. This leads to reduced dielectric loss, enhanced dimensional stability, and decreased X/Y/Z anisotropy of the material. It also broadens the usable frequency range, boosts electrical strength, and improves thermal conductivity. Moreover, the material shows excellent low thermal expansion coefficient and stable dielectric temperature characteristics.

The F4BTMS series laminates comes with RTF low roughness copper foil as a standard feature, reducing conductor loss and providing excellent peel strength. It can be used with either copper or aluminum bases. For example, the F4BTMS615 PCB has a dielectric constant (Dk) of 6.15 at 10GHz, a dissipation factor of.0020 at 10GHz and 0.0023 at 20GHz. It features a CTE x-axis of 10 ppm/°C, CTE y-axis of 12 ppm/°C, CTE z-axis of 40 ppm/°C within the temperature range of -55°C to 288°C. It also has a low thermal coefficient of Dk at -96 ppm/°C from -55°C to 150°C, a high thermal conductivity of 0.67 W/mk, and a moisture absorption of 0.1%.

Our new product is a 2-layer rigid PCB with a stackup of Copper_layer_1 - 35μm, F4BTMS615 Core - 5.08 mm (200mil), and Copper_layer_2 - 35μm. The type of artwork supplied is Gerber RS-274-X, and it adheres to the IPC-Class-2 quality standard. It is available worldwide and finds typical applications in aerospace equipment, space and cabin equipment, microwave, RF, radar, military radar, feed networks, phase-sensitive antennas, phased array antennas, satellite communications, and more.

Looking ahead, industry analysts predict that as the Internet of Things (IoT) expands, connecting billions of devices, the demand for reliable and affordable high-frequency PCBs will skyrocket. With the innovative F4BTMS series, it is well-positioned to thrive in this exciting industry landscape.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com