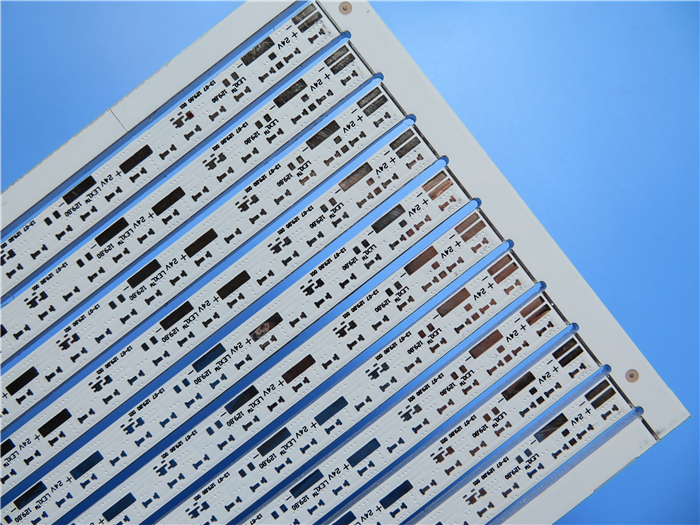

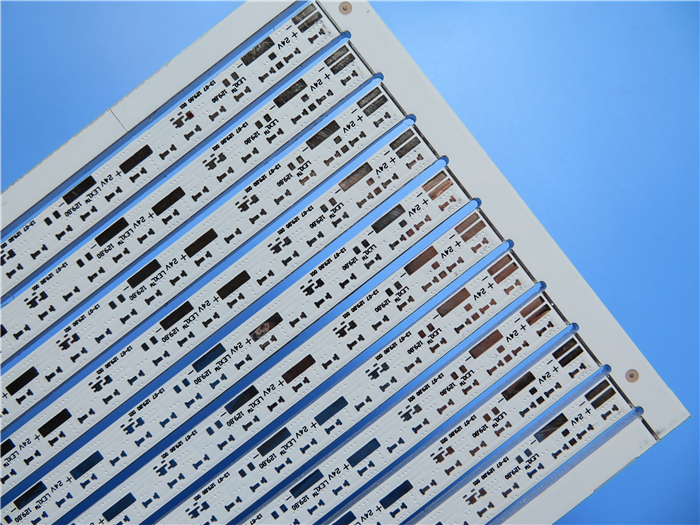

Aluminum Circuit Board Manufacturing and What Manufacturing Difficulties & Matters Needing Attention

As the substrate material of

PCB aluminum substrate manufacturing, aluminum clad plate mainly plays the role of interconnecting conduction, insulation and support to aluminum PCB substrate, and has great influence on signal transmission speed, energy loss and characteristic impedance in circuit. The performance, quality, manufacturability, manufacturing level, manufacturing cost, and long-term reliability and stability of PCB aluminum substrate are largely determined by aluminum clad copper plate. Aluminum based circuit boards have excellent electrical performance, heat dissipation, electromagnetic shielding, high dielectric strength and bending resistance. As a metal core PCB, whether it is single,

double-side aluminum pcb or

multi-layer aluminum circuit board, they have many similarities with FR4 circuit board in the manufacturing process, such as etching thick copper foil, aluminum surface etching protection, aluminum plate manufacturing and solder blocking printing. However, as a kind of advanced PCB, aluminum base PCB still has special aspects of manufacturing process, which requires strict and effective management and control. So, what are the precautions and manufacturing difficulties in aluminum based circuit board production?

Machining: Drilling aluminum substrate can be done, but the inner edge of the drilled hole should not have any burrs, which will affect the pressure test. Milling the profile is very difficult. And the shape, the need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After the shape is flushed, the edge is required to be very neat, without any burr, and does not touch the welding resistance layer of the plate edge. Usually use the soldier die, hole from the line, shape from the aluminum surface, circuit board when the force is on the shear pull, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

The whole production process is not allowed to wipe the aluminum base surface: the aluminum base surface by hand touch, or by some chemicals will produce surface discoloration and blackening, which is absolutely unacceptable. Some customers do not accept the re-polishing of the aluminum base surface, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base circuit board. Some enterprises use passivation process, some in hot air leveling (tin spraying) before and after each affixed with a protective film many small skills, the eight imfairy across the sea, each brilliant.

Over high voltage test: aluminum base plate of communication power supply requires 100% high voltage test. Some customers require DIRECT current, and some require alternating current. The voltage is 1500V and 1600V, and the time is 5 seconds and 10 seconds. Dirt, holes, aluminum edge burrs, line serrations, and any damage to the insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board layer, bubble, are rejected.

Thick copper foil etching

Aluminum based circuit boards are commonly used in power equipment with high power density, so the copper foil is relatively thick. When copper foil thickness is 3oz or greater, etching copper foil requires trace width compensation. Otherwise, the line width after etching will be outside the tolerance range. Therefore, in order to ensure that the best wiring width/spacing and impedance control can meet the design requirements, the work that must be completed in advance should be properly designed for wiring width compensation; The influence of wiring manufacture on wiring width/spacing should be eliminated. Etching factors and reagent parameters should be strictly controlled.

Solder resist printing

Due to the role of thick copper foil, solder blocking printing is considered to be difficult to manufacture aluminum based circuit boards. If the copper thickness of the wire after the image etching is too large, there will be a large difference between the wire surface and the substrate, and the solder resistance layer will become difficult. In order to ensure smooth welding printing, welding oil should be absorbed with high quality performance, and welding printing can be used twice. If necessary, the manufacturing method of first filling resin and then printing welding can be used.

Machinery manufacturing

Mechanical manufacturing of aluminum-based circuit boards or

2 layer aluminum pcb involves mechanical drilling, milling and molding, as well as v-cutting, which often leaves burrs in the internal through-holes that reduce electrical strength. Therefore, in order to ensure high quality mechanical manufacturing, small batch production, should choose electric milling cutter and professional milling cutter, in the process of molding should pay attention to the control technology and pattern, should be in the thick copper aluminum based circuit board on the appropriate adjustment of drilling parameters, in order to prevent burrs. Bicheng can batch produce 4-46 layer PCB board, circuit board,

wholesale aluminum pcb, high frequency board, high speed board,HDI board, PCB board, high frequency high speed board, double-sided, multi-layer PCB board,HDI board, mixed pressure circuit board, high frequency circuit board, hybrid board and so on

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com