BASE MATERIALS OF PCB

The insulation, material makeup, and fire-retardant properties of the base materials are frequently used to classify substrates. Bakelite, fiberglass, and various plastics are common PCB base materials. Manufacturers of

PCB substrates typically combine insulating prepreg materials made of glass-fiber non-woven material and epoxy resin laminated to copper foil to create copper foil substrates.

The common types of PCB substrates are as follows :

FR-4: Fiberglass + Epoxy Resin. This is the most common type of PCB substrate. As Tg is only about 130°C, the

High Tg FR-4 is recommended for products requiring processing or operating at high temperatures.

High Tg FR-4: Fiberglass + Epoxy Resin. This is the second common type of PCB substrates after the FR-4 PCB substrates with a glass transition temperature (Tg) over 150°C is called High Tg substrates.

CEM-1: Fiberglass Fabric + Epoxy Resin coated on cotton.

CEM-3: Fiberglass Fabric + Epoxy Resin coated on fiberglass non-woven fabrics.

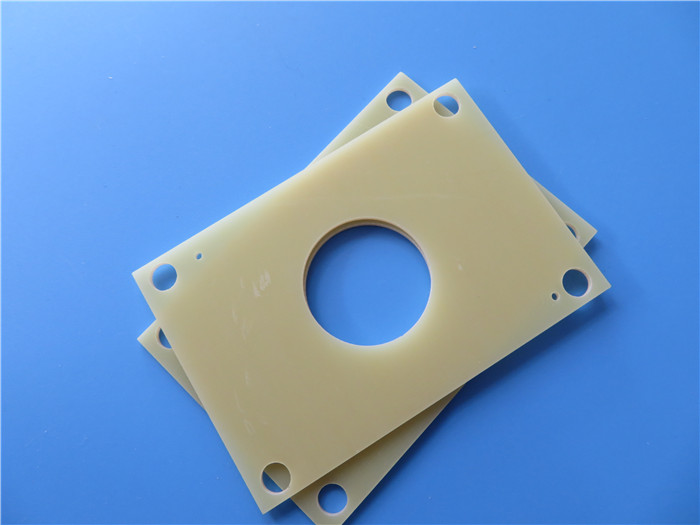

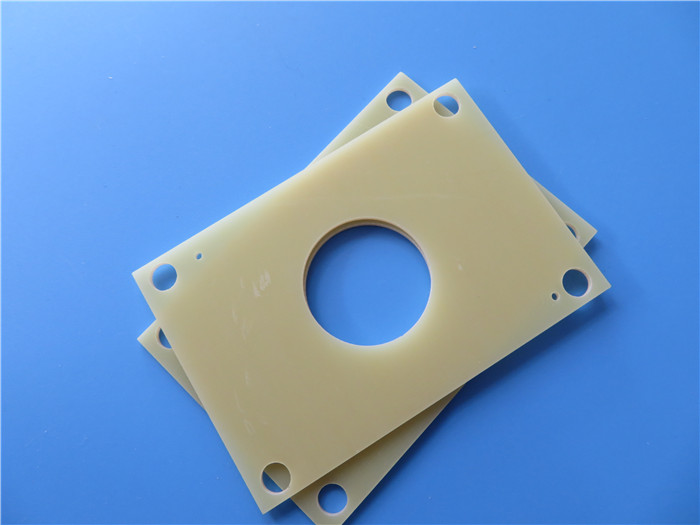

Ceramic PCB: Powder Ceramics + Fiberglass

Surface treatment of PCB:

Due to the PCB's copper surface's propensity for oxidization in the presence of oxygen, exposed regions that aren't covered by the solder mask are given a surface coating to prevent oxidation. Surface finishes of diverse materials, costs, and protection capabilities are produced to fulfill the requirements of various ways of post-processing.

These are the typical PCB surface finishes:

Surface treatments include immersion silver, gold plating, HAL, LF-HASL, ENIG, and bare copper. To examine a comparison of several PCB surface finishes.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com