How to Make a High Tg PCB and What Materials Should Be Used

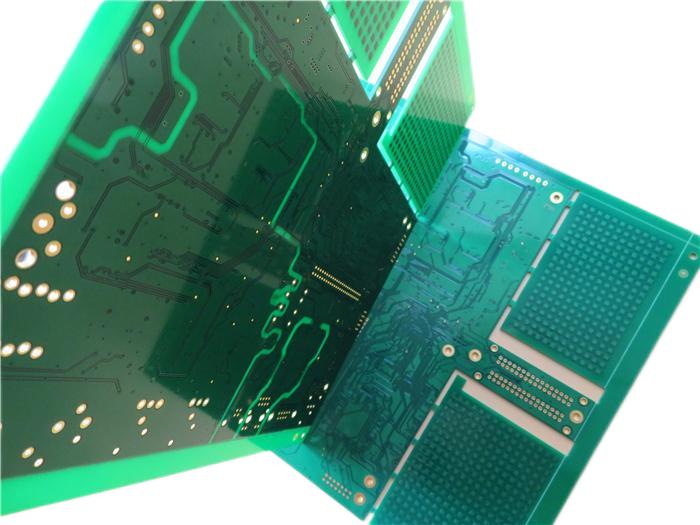

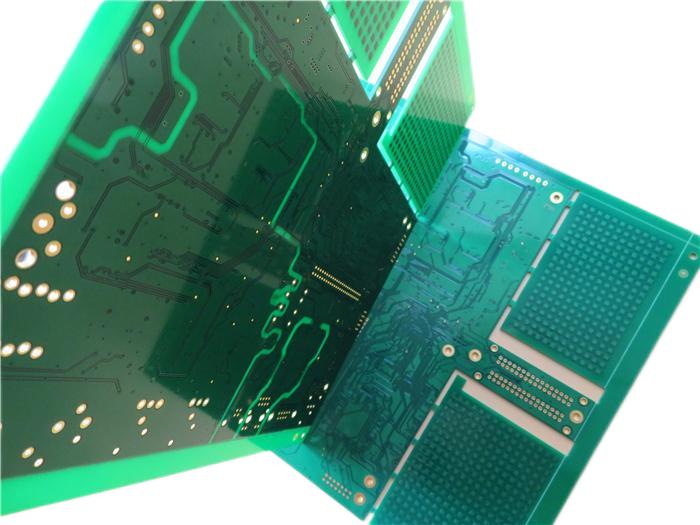

With the rapid development of the electronics sector, particularly electronic devices, better heat resistance of PCB substrate materials is becoming a crucial assurance.

Because of the advent and development of high-density mounting technologies like as SMT (surface mount technology) and CMT, PCB has become inextricably linked to high heat resistance capabilities in terms of small aperture, fine line, and thinning. That is why

high Tg PCB is becoming more popular. In this post, we will look at how high Tg PCBs are made and what materials should be utilized to make them.

What do we know about high Tg PCB?

When electricity travels across circuit boards, heat is generated. Heat resistance is essential for circuit boards to function properly. Circuit boards can fail due to excessive heat from the circuit board and high ambient temperatures. As a result, they must be heat resistant.

In PCBs, TG stands for heat resistance. The raw materials used in the manufacture of PCBs affect how much heat a circuit board can withstand before failing. This page covers all you need to know about high TG PCBs.

What materials are suitable for high Tg PCB?

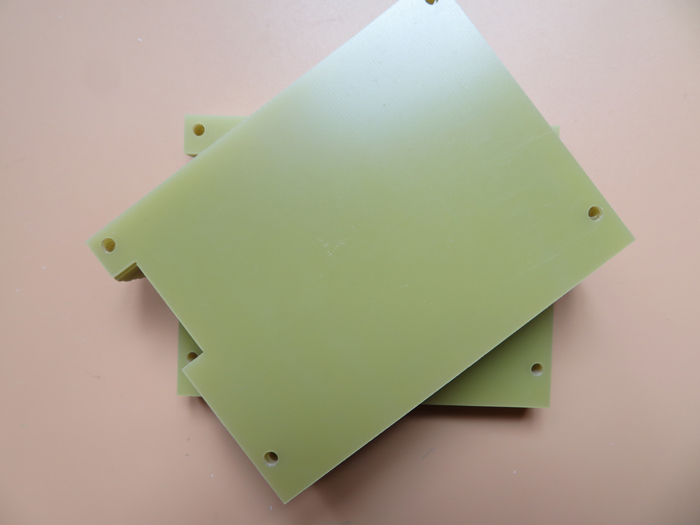

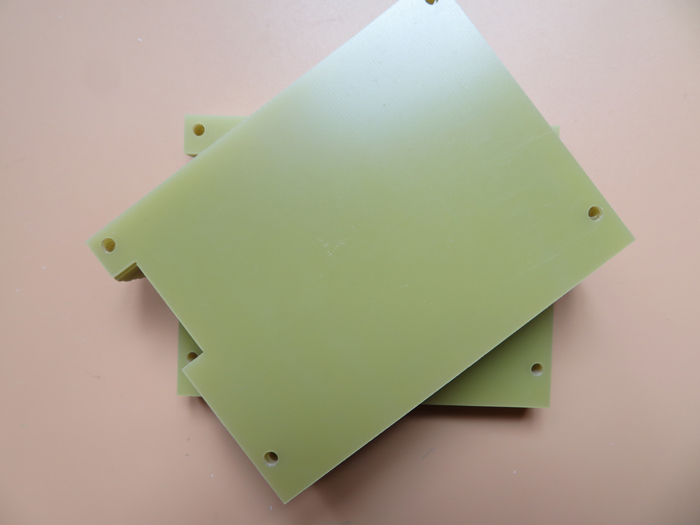

The flame resistant material should be carefully evaluated. Glass epoxy is a flame-resistant substance. As a result, polymers and composites containing or manufactured of epoxy resins become the main choice for high Tg PCB production. Here are some materials to get you started.

FR4 stands for glass fiber reinforced epoxy laminate. FR is an abbreviation for flame retardant. The FR4 material has passed the UL94V-0 flame retardant test. FR4 has electrical resistance performance in both dry and wet conditions. As a result, FR4 can better replicate heat dissipation caused by dielectrics and conductors.

Here are some common ISOLA materials used in the production of high Tg PCBs.

IS410: It can endure 180°C Tg as a FR4 laminate and prepreg material. It can also withstand several thermal excursions and passed the 6X solder test at 288°C. It is also possible to use a high tg PCB for lead-free soldering.

IS420 is a multipurpose epoxy resin with a good performance. It has greater thermal qualities and low expansion performance than typical FR4 materials, and it can block UV rays and is suitable with AOI machines. (automated optical inspection).

G200 is an epoxy resin and bismaleimide/triazine mixture. (BT). It has a strong heat resistance capacity as well as good electrical qualities.

Except the above materials, there also have other materials like S1000, ITEQ IT-180A, ARLON 85N that can also be selected for high tg PCB manufacturing.

What are the characteristics of a high Tg PCB?

A PCB with a high TG will have the following qualities and characteristics:

They have a high heat resistance and are suitable for usage in hot and humid regions such as those found in Africa, Latin America, and South Asia.

Thermal shock resistance is high on high TG boards. They can resist extremely high amounts of thermal stress without flaws or damage.

PCBs with a high TG have a low Z-axis CTE and a high level of PTH dependability.

What are pros and cons of high Tg PCB?

Advantages

1.A PCB has a high level of stability, even during severe operations.

2.High power density circuit designs can be printed on a PCB with a high TG.

3.Such PCBs are an excellent alternative for equipment with limited air flow. These settings have high ambient temperatures, which high TG PCB can withstand.

Disadvantages

1.Their manufacturing is a little complicated and costly since the maker must integrate rare raw materials.

2.High TG PCBs are difficult to find in the local market. You must make contact with a supplier.

3.Buying in small numbers will be difficult because suppliers rarely sell retail quantities at a reasonable price.

In which applications can high TG PCB be used?

Engine Control Modules

Engines generate a lot of heat, hence only a high TG PCB may be utilized to make an engine controller. Not only can these PCBs endure heat, but they can also perform well in the long run.

Metal Processing Units

Metal-processing devices, such as cutting, molding, and CNC, generate high heat levels, making a high TG PCB the best solution for creating circuit boards for these machines.

Hot Cutting Machines

Machines that employ the hot cutting technique to cut plastic sacks and other fabrics require a controller and circuit board that can operate under tremendous stress. This is where high TG PCBs can be used.

Super Computers

Super computers and severs run 24/7 without any scope of rest. Therefore, in order to ensure quality performance throughout the life of a server or a super computer, it’s safe to use a high TG PCB.

FR4 TG 150 Vs. FR4 TG 170

The numbers 150 and 170 denote ideal tolerable temperature in degrees Celsius. Any PCB marked as “

FR4 TG150” can withstand heat temperatures from 130 degrees Celsius to 150 degrees Celsius.

PCBs marked as “

FR4 TG170” have an ideal tolerable temperature range of 150 degrees Celsius to 170 degrees Celsius. Therefore, FR4 TG 170 is a superior version of FR4 TG 150.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com