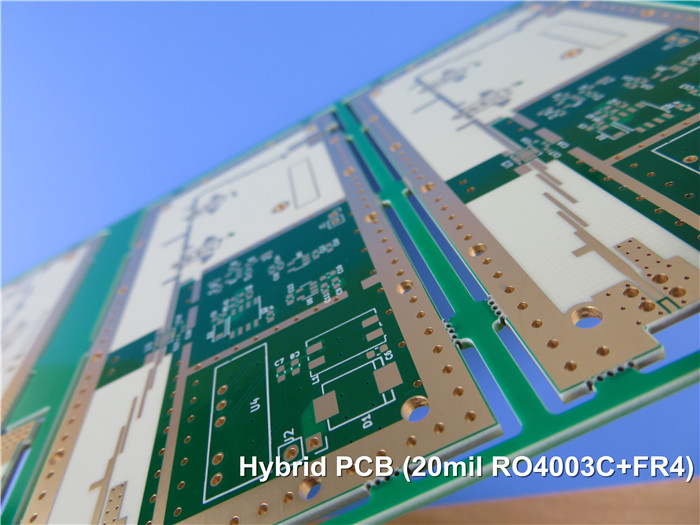

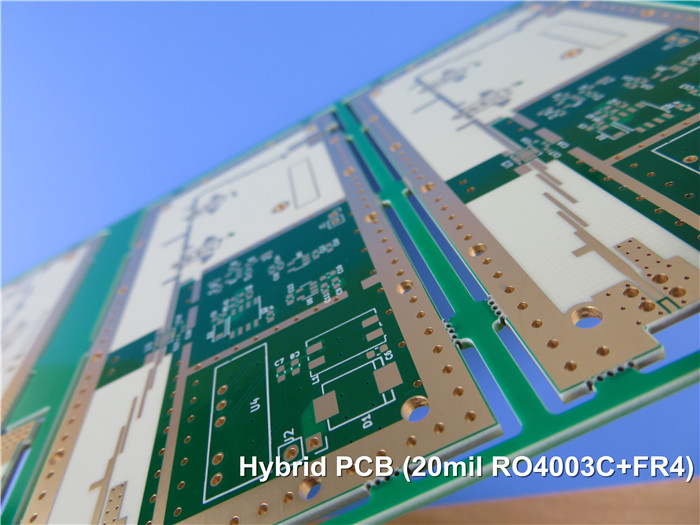

Hybrid PCBs: Bridging the Gap Between High-Frequency Materials and FR4 in the PCB Industry

Introduction:

In the fast-paced world of electronics, the demand for high-performance printed circuit boards (PCBs) continues to rise. Engineers and manufacturers are constantly seeking innovative solutions to meet the requirements of cutting-edge technologies. One such emerging trend is the use of hybrid PCBs, which combine high-frequency materials with traditional FR4 substrates. This article delves into the world of hybrid PCBs, exploring their benefits, applications, and the impact they have on the PCB industry.

Understanding Hybrid PCBs:

Hybrid PCBs are a blend of different materials within a single circuit board. These boards typically incorporate high-frequency materials, such as polytetrafluoroethylene (PTFE), alongside the commonly used FR4 substrate. The combination aims to capitalize on the advantages of both materials, addressing the need for high-frequency performance while maintaining cost-effectiveness and ease of manufacturing.

Benefits of Hybrid PCBs:

a. Enhanced High-Frequency Performance: The integration of high-frequency materials allows hybrid PCBs to deliver excellent signal integrity, reduced transmission losses, and improved impedance control. This capability is crucial for applications involving high-speed data transfer, wireless communication, and RF devices.

b.Cost-Effectiveness: Hybrid PCBs strike a balance between high-performance materials and cost efficiency. By selectively using high-frequency materials only where necessary, manufacturers can optimize the board's performance while minimizing costs associated with producing an entire board from costly materials.

c.Manufacturing Simplicity: Hybrid PCBs offer a practical solution for manufacturers with existing FR4 production capabilities. By incorporating high-frequency layers only where required, manufacturers can leverage their existing processes and infrastructure, reducing the need for significant investment in new equipment or training.

Applications of Hybrid PCBs:

Hybrid PCBs find applications in various industries that require reliable high-frequency performance, such as:

a. Telecommunications: Hybrid PCBs enable the development of advanced wireless communication systems, including 5G infrastructure, satellite communication, and IoT devices.

b. Aerospace and Defense: The demanding requirements of aerospace and defense applications, such as radar systems, satellite communication, and avionics, can benefit from the performance and cost advantages offered by hybrid PCBs.

c. Automotive: Hybrid PCBs in automotive applications handle data communication, radar systems, and high-speed electronic control units (ECUs), contributing to advanced driver assistance systems (ADAS) and autonomous vehicles.

Impact on the PCB Industry:

The emergence and adoption of hybrid PCBs have significant implications for the PCB industry:

a. Technological Advancement: Hybrid PCBs push the boundaries of high-frequency performance, enabling the development of next-generation electronics that demand exceptional signal integrity.

b. Market Growth and Diversification: By incorporating high-frequency materials into traditional FR4 designs, manufacturers can cater to a broader range of applications, expanding their customer base and driving market growth.

c. Collaboration and Knowledge Exchange: Hybrid PCBs require collaboration between traditional PCB manufacturers and high-frequency material experts. This collaboration fosters knowledge exchange and expertise sharing, fueling innovation in both fields.

Conclusion:

Hybrid PCBs represent a promising solution in the PCB industry, offering the best of both worlds by combining the high-frequency performance of specialized materials with the cost-effectiveness and ease of manufacturing associated with FR4 substrates. As technology continues to advance, the demand for high-performance PCBs will only increase. Hybrid PCB provide a versatile platform for engineers to meet the evolving demands of modern electronics, driving innovation and propelling the industry forward.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com