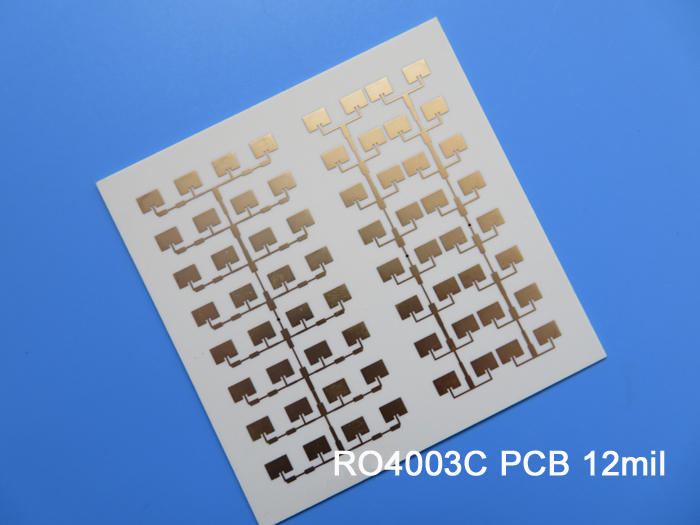

RO4003C Rogers 12mil High Frequency PCB-PCB Industry Experiences Rapid Growth in High-Frequency Applications Demand

With the continuous advancement of technology, the demand for high-frequency applications has rapidly expanded across various industries. This unprecedented growth presents significant opportunities for the Printed Circuit Board (PCB) industry. High-frequency applications have become crucial technological requirements in fields such as communication, electronics, automotive, aerospace, and more, driving the rapid rise of the PCB industry.

Meeting the demands of high-frequency applications requires PCB design, manufacturing, and performance to meet higher standards. Consequently, many PCB suppliers and technology providers have introduced solutions tailored for high-frequency applications.In order to change this situation, BICHENG also provide a new shipped 12mil Rogers RO4003C PCB Material for High-Frequency Applications.

Here is our new shipped 12mil RO4003C PCB detailed information:

Material Advancements:

Rogers RO4003C stands out as a highly regarded Rogers PCB material for high-frequency applications. It utilizes woven glass reinforced hydrocarbon ceramic material, offering excellent signal integrity and low loss coefficients. With a dielectric constant of 3.38 at 10 GHz/23°C and a loss factor of just 0.0027, it effectively reduces signal attenuation. Additionally, RO4003C exhibits exceptional high-temperature resistance, ensuring stable operation across a wide temperature range.

Rogers RO4003C PCB 12mil Material for High-Frequency Applications:

Experience superior performance with our hydrocarbon ceramic woven glass material

Processed with DK 3.38 at 10 GHz/23°C, ensuring optimal signal integrity

Low dissipation factor of 0.0027 at 10 GHz/23°C for minimal signal loss

Withstands high temperatures, boasting a Tg >280°C and Td >425°C

Suitable for operation in a wide temperature range of -40℃ to +85℃

Boost Your RF Design with our12mil RO4003C2-layer Rigid PCB Stackup

Utilizes Rogers 4003C substrate with a thickness of 0.305mm

Copper layer thickness of 35μm on both the top and bottom layers

Achieve precise trace and space requirements with a minimum of 4/4 mils

Accommodates 0.25mm minimum hole size for various component needs

Finished board thickness of 0.43mm for compact and lightweight designs

Unveiling the Construction Details of our High-Quality PCB

Board dimensions of 170.53mm x 180.35mm, offering flexibility for different applications

A total of 115 components and 217 pads for comprehensive functionality

Includes 112 through-hole pads and 105 top SMT pads for versatile component placement

Vias totaling 168 for efficient signal routing and connection

Adheres to IPC-Class-2 standard to ensure reliable and consistent quality

Trustworthy Quality and Global Availability

Each board undergoes a 100% electrical test before shipment, ensuring reliability

Supplied with Gerber RS-274-X artwork for seamless manufacturing integration

Accepted standard of IPC-Class-2 guarantees high-quality production

Available for purchase worldwide, facilitating easy access for all customers

To meet the design requirements of high-frequency applications, manufacturers have introduced a 2-layer rigid PCB stack-up solution. By utilizing Rogers 4003C 12mil substrate and a 35μm copper layer thickness, this solution enables precise circuit layout and spatial requirements. Furthermore, the design accommodates minimum hole sizes of 0.25mm to meet various component needs. With a board thickness of 0.43mm, it achieves compact and lightweight designs.

In addition to material and design innovations, manufacturers also prioritize the quality and reliability of PCBs. Adopting IPC-Class-2 standards ensures high-quality production processes and consistency. Each PCB undergoes 100% electrical testing before shipping to ensure reliability.

The rapid growth of high-frequency applications has garnered attention from the global PCB industry. Whether it's communication equipment manufacturers or satellite technology companies, they can easily access high-frequency PCB products that meet their specific needs.

Conclusion:

The PCB industry is experiencing rapid growth, driven by the escalating demand for high-frequency applications. From wireless communication and radar systems to satellite communications, the introduction of high-frequency PCB products will further propel the industry's development. With continuous technological advancements, we can expect the PCB industry to bring more innovation and breakthroughs in the field of high-frequency applications, providing robust support for the growth of various industries.

For any technical inquiries or further information, please reach out to Jane at sales20@bichengpcb.com. We are here to support your PCB needs and deliver exceptional performance for your high-frequency applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com