What exactly is PCB Substrate Material?

PCB substrate material is the primary material used in the construction of a circuit board. This material also ensures that the circuit uses the least amount of electricity. A good example of a PCB substrate material is FR4. Epoxy resin is used to reinforce the majority of these materials. Furthermore, these substrate materials are widely used in the manufacture of printed circuit boards.

Substrate Material Varieties

There are various substrate materials. Each of these PCB substrate materials has unique properties. These materials are also suitable for a variety of applications. The type of substrate used will be determined by the application of these boards.

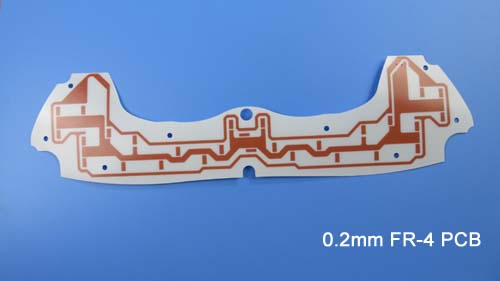

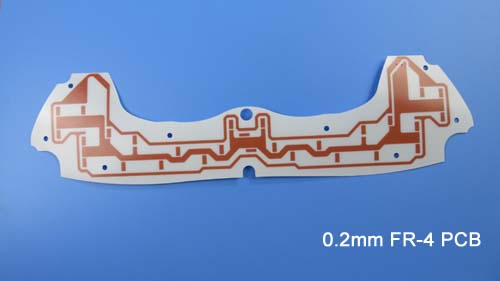

FR4 is a widely used PCB substrate material. It is a glass fabric reinforced laminate impregnated with flame-resistant epoxy resin. Prepreg sheets are used to create this versatile material. Furthermore, in terms of metallization and ease of drilling, FR4 is the industry standard. The "FR4" designates a material class that meets the NEMA LI 1-1998 standards.

The mechanical, thermal, and electrical properties of this substrate material. FR4 has a glass transition temperature of 135 Celsius. This material is therefore perfect for use in high-density applications. Moreover, the strength-to-weight ratio of this substrate material is high. Yet there are certain restrictions on this information. Its significant dielectric loss prevents it from being used in high-speed digital circuits.

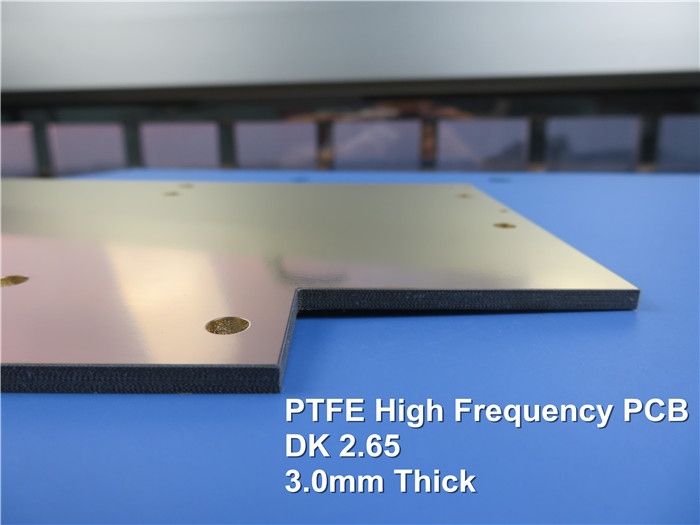

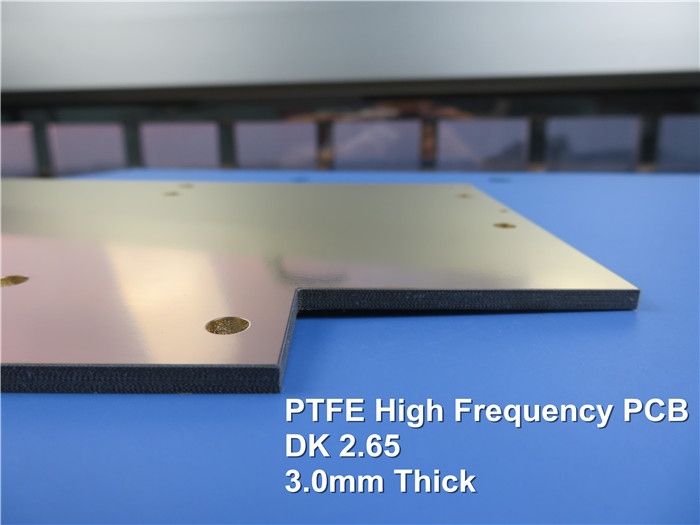

One of the best PCB substrate materials is PTFE, commonly known as polytetrafluoroethylene. It is the best option for microwave and high power Boards. Moreover, PTFE has strong dielectric properties and high heat conductivity. Even at very low temperatures, it keeps up its strong flexural strength.

PTFE is a flexible fluoropolymer of plastic that can be used in a variety of applications. It is frequently employed in the aerospace and defense industries. PTFE has a melting point at 327 degrees Celsius. This substance is also thermally stable and chemically inert. The substrate of a PCB made of PTFE will be corrosion-resistant. This is due to the material's ability to ward against water and grease. Also, this material is friendly to the environment.

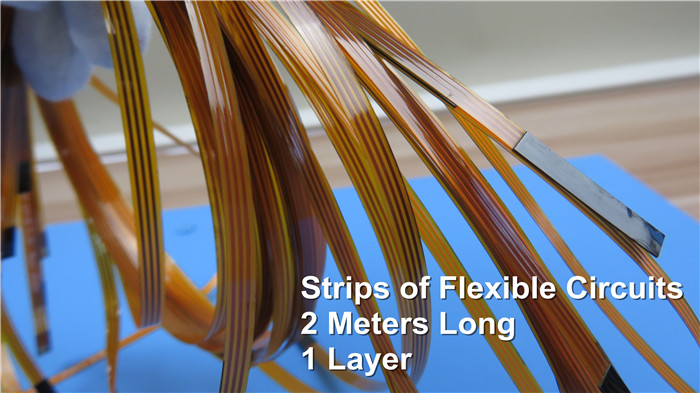

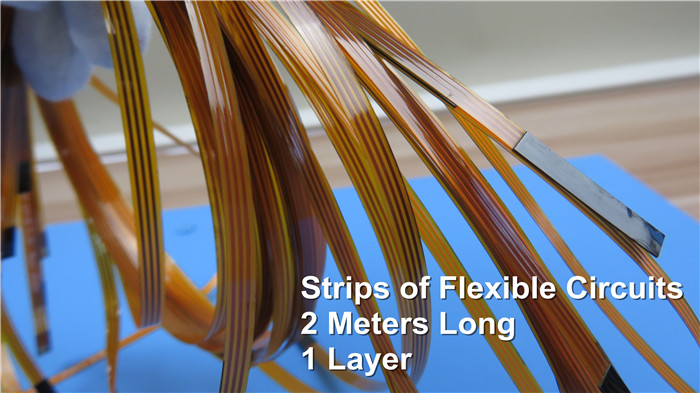

This substrate material performs better at higher temperatures. Compared to FR4, polyimide materials are more expensive. This material offers improved resistance to abrasive temperature situations. Moreover, they have less expansion qualities. They are therefore perfect for building higher layer PCB because of this. Moreover, polyimide is chemically resistant. Polyimide PCBs are capable of operating under corrosive conditions.

Due to its strength and flexibility, polyimide material is frequently employed. Moreover, this PCB substrate has great flexibility and thermal stability. The fabrication of rigid-flexible and flexible PCBs frequently uses it. Despite its suppleness, this material is resistant to warping. It is also the best option for applications that require physical durability. Polyimide can withstand thermal abrasion during production.

CEM

In comparison to FR-4 material, this is less expensive. CEM is an acronym for composite epoxy material. There are various categories of CEM material. They consist of CEMs 1, 2, and more. Only single-sided boards can be made using CEM 1. Paper, phenolic chemicals, and woven glass epoxy are also used to make CEM. For making double-sided boards, CEM 3 is the best material. A glass temperature of 122 degrees Celsius is seen in CEM 1. Moreover, CEM 2 has a 125 degree Celsius glass temperature. A glass temperature of 125 degrees Celsius is seen in CEM 3.

Alumina

This substrate material, which is based on ceramics, is excellent for usage in high frequency applications. It is the best substrate material for PCBs made of ceramic. This substance has excellent heat conductivity. Also, it is economical. As a result, it is frequently utilized in PCB construction. Heat from vital parts can be transmitted through alumina. It is therefore perfect for high-power boards.

Conclusion

A circuit board's functionality and performance are influenced by the PCB substrate materials. Knowing the different sorts and what they offer is crucial. Information on the various substrate materials is provided in this article. Also, it offered crucial guidance on how to pick these materials. These substrate materials all have various advantages.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com