What is the difference between PCB and metal core PCB?

One important difference to understand between

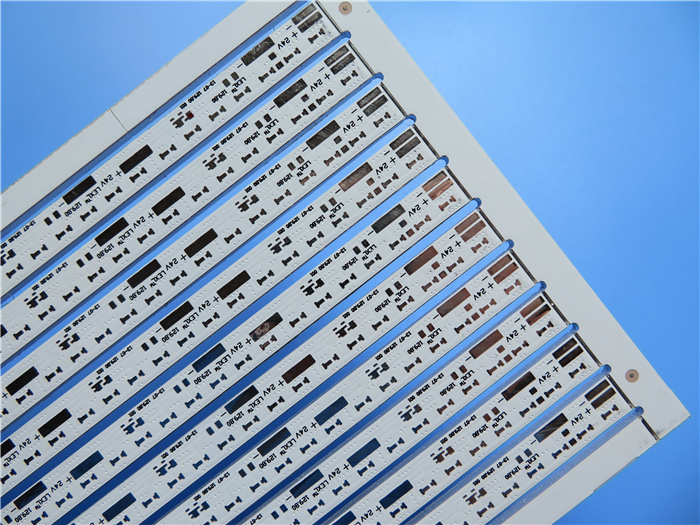

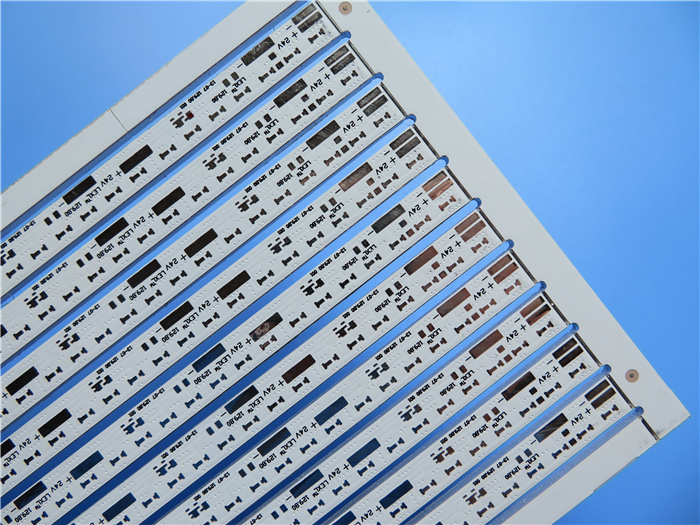

metal core PCB and standard PCB is how the materials work together to create the necessary result. In metal core PCB, there is a single layer of copper with is bonded to a layer of conductive dielectric material, which is further bonded to a thick metal layer (typically Aluminum 5052, Aluminum 6061, or Copper C1100). The dielectric used is approximately 6-7 times as thermally conductive as FR4. The dielectric is to be kept as thin as possible. This reduces the distance from the heat source to the metal plate which is more conductive than the dielectric.

As you know, the metal plate on the bottom side is the thickest element in the structure. It is available in several different thicknesses, however, there are three most common thickness, such as 1.0mm, 1.5mm, and 3.2mm as they are the easiest to purchase. The metal also gives the PCB rigidity and does not require any surface finish or solder mask.

FR-4 PCB Vs. Metal core PCB comparison

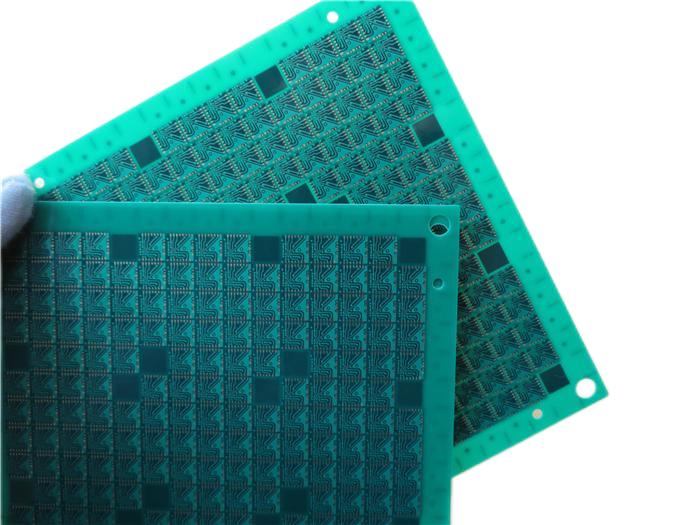

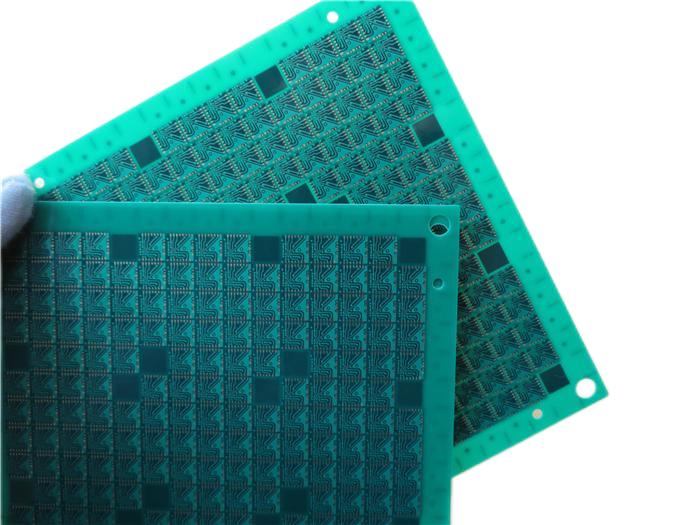

Plated through holes: in general, plated through holes are used in

FR-4 PCB. It can be through hole components if required. In metal core PCB, plated through holes are not available for 1-layer PCB. All components are surface-mounted.

Conductivity: FR-4 PCB has low thermal conductivity, in general about 0.3W, however, MCPCB has a higher thermal conductivity between 1.0W and 4.0W, most commonly about 2.0W.

Thickness: FR-4 PCB has a wide range of thickness, also uses many material combinations and layers. Metal core PCB has a limited thickness variation.

Thermal relief: as usual, Thermal relief in FR4 PCB involves vias for heat transfer. And it has a longer drilling processing cycle. Metal core PCBs don’t require via as their own thermal dissipation. Consequently, they do not require drilling, deposition and plating processes.

Solder mask: FR-4 PCB solder mask is dark colors such as green, red, black and so on, which usually applied on top and bottom. For LED boards, metal core PCB solder mask are almost exclusively white and they are only applied to the top.

Machining process: FR-4 PCB uses standard processing such as drilling, routing, v-scoring, countersink, counterbore and so on. whereas in metal core PCBs, there is a distinctive difference in the v-scoring process i.e. diamond-coated saw blades are used for the added strain from cutting into metal.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com