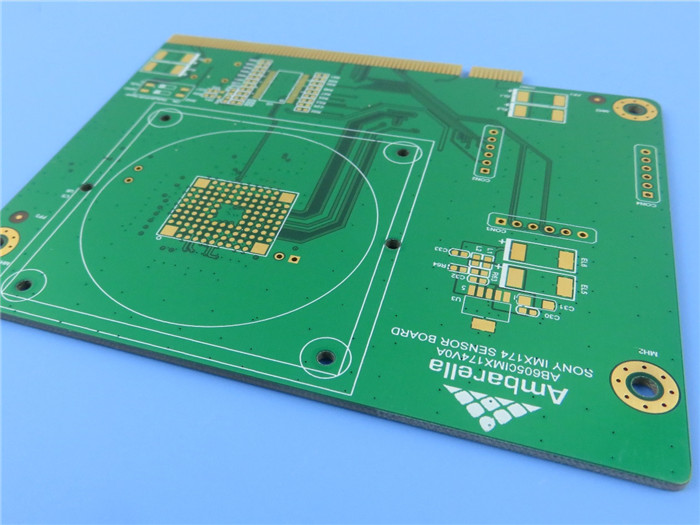

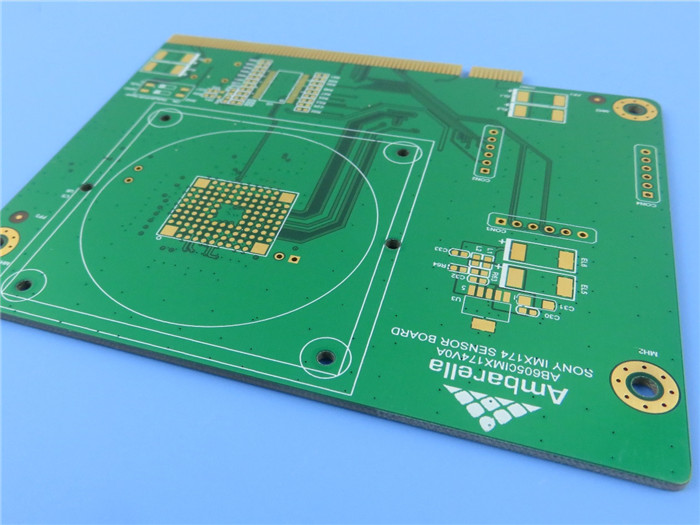

What Makes the HDI PCB Different?

The advantages of HDI PCBs over ordinary PCBs are listed below, demonstrating how they differ from other kinds of PCBs.

1. Enhanced Thermal Efficiency

Due to the use of copper foil rather than aluminum foil in

FR4s,

HDI PCBs have higher thermal performance. In comparison to aluminum, copper is a far superior heat conductor and can dissipate heat much more effectively. Less power is wasted as a result, which is crucial when working with high-power circuits like motor drivers or power supplies.

2. Improved Signal Integrity

Because signal traces from multiple layers can be routed closer together on the same plane,

HDI pcb boards are able to retain signal integrity over longer distances than conventional

single-layer boards. Additionally, due to capacitance effects, signal traces on one layer can be routed over other traces on another without degrading the quality of the signal.

3. Increasing Reliability

By enhancing the insulation between conductors and circuits, lowering crosstalk, and preventing short circuits between signals moving on neighboring planes, HDI pcb boards improve system dependability. Additionally, they improve mechanical strength by lowering stress concentrations brought on by densely packed components in high numbers.

4. Greater Density

Compared to conventional single-layer boards, HDI pcb boards support more electrical connections per unit space. The usage of several layers in the stackup and blind vias as layer interconnects are mostly to blame for this.

5. More Compact Size

HDI PCBs are more compact than conventional PCBs because of the enhanced trace density. As a result, they take up less space on one board, making them perfect for portable gadgets like laptops, tablets, and smartphones. Additionally, because of their reduced size, they are simpler to manufacture on a single assembly line without the need for special tools for each product's various sizes.

6. Mechanical Power

Standard PCBs cannot sustain the amount of stress that HDI PCBs. This is a result of their construction, which consists of several sheets of thin plastic linked together with an epoxy adhesive. Depending on the kind of resin used in construction, each layer's strength varies.

7. Lower Price

HDI pcb boards can be less expensive than other kinds of

multilayer boards and other kinds of boards produced from copper-clad laminate because they are easier to make and less expensive to create than single-sided boards (CCL). Both low-volume production runs and high-volume production runs are compatible with them.

HDI PCBs for a Variety of Applications

Where reliability is crucial, HDI PCBs are frequently utilized in avionics, military, and aerospace applications. A typical airplane requires hundreds of microcircuits, sensors, and other electronic parts, all of which must be wired together. The conventional method calls for all of these wires to be soldered directly on top of one another, which frequently results in a number of issues. For example, connections between devices may weaken over time due to thermal stress or vibration; wires may become loosened during flight due to vibrations; or cracks may form between different layers of the board due to problems with thermal expansion.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com