Advantages, Disadvantages and Development Trends of FPC Flexible Circuit Boards

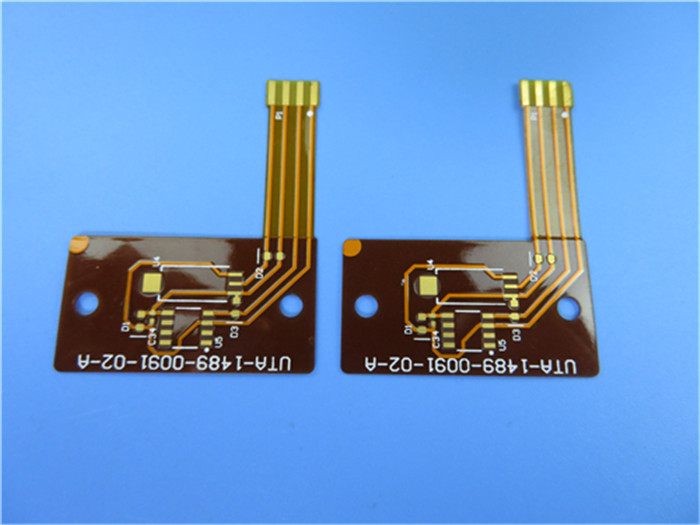

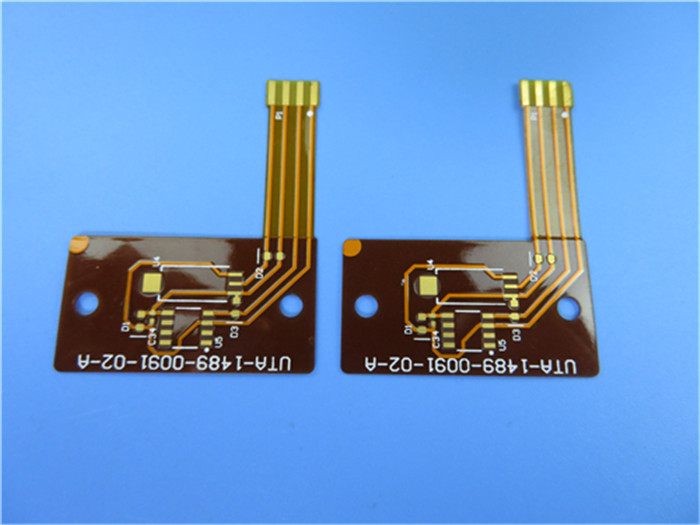

FPC flexible circuit board is a highly reliable, excellent flexible circuit board made of flexible insulating substrates such as polyimide or polyester film. Sexual printed circuit board. It has the characteristics of high wiring density, light weight, thin thickness and good bendability.

Flexible printed circuit boards are also divided into single-sided, double-sided and multi-layer boards. Flexible circuit boards are mainly used in the connection parts of electronic products. The advantage is that all lines are configured. It can improve the softness by eliminating the need for connecting workers of redundant cables. Strengthening the assembly of three-dimensional space in a limited space can effectively reduce the volume of the product. It increases the convenience of carrying and also reduces the weight of the final product.

Features of flexible circuit boards:

1. Short assembly time: all lines are configured, eliminating the need to connect redundant cables.

2. Smaller in volume than PCB: It can effectively reduce the volume of the product and increase the convenience of carrying.

3. Lighter weight than rigid PCB: It can reduce the weight of the final product.

4. The thickness is thinner than the PCB: it can improve the softness and strengthen the assembly of three-dimensional space in a limited space.

Advantages of flexible circuit boards:

Flexible printed circuit boards are printed circuit boards made of flexible insulating substrates and have many advantages that rigid printed circuit boards do not have:

1. It can be bent, wound, and folded freely, and can be arbitrarily arranged according to the spatial layout requirements, and can be moved and stretched arbitrarily in three-dimensional space, so as to achieve the integration of component assembly and wire connection.

2. The use of FPC can greatly reduce the volume and weight of electronic products, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptop computers, computer peripherals, PDA, digital cameras and other fields or products.

3. FPC also has the advantages of good heat dissipation and solderability, easy assembly and connection, and low comprehensive cost. The design of soft and hard combination also makes up for the slight deficiency of the flexible substrate in the component carrying capacity to a certain extent.

Disadvantages of flexible circuit boards:

1. High one-time initial cost: Since flexible PCBs are designed and manufactured for special applications, the initial circuit design, wiring, and photographic plates require higher costs. Unless there is a special need to apply a flexible PCB, it is usually best not to use it in a small amount of applications.

2. It is difficult to change and repair the flexible PCB: once the flexible PCB is made, it must be changed from the base map or the compiled light drawing program, so it is not easy to change. The surface is covered with a protective film, which must be removed before repairing and restored after repairing, which is a more difficult task.

3. Size is limited: Flexible PCBs are usually manufactured by batch process when they are not yet common. Therefore, due to the limitation of the size of production equipment, they cannot be made very long and wide.

4. Improper operation is easy to damage: improper operation of the installation and connection personnel can easily cause damage to the flexible circuit, and its soldering and rework need to be operated by trained personnel.

Electronic products must use PCB, and the market trend of PCB is almost the vane of the electronics industry. With the development of high-end, miniaturized electronic products such as mobile phones, notebook computers and PDAs, the demand for flexible PCBs (FPCs) is increasing, and PCB manufacturers are accelerating the development of thinner, lighter and denser FPCs. The

single-layer FPC has a conductive pattern etched by chemical etching, and the conductive pattern layer on the surface of the flexible insulating substrate is a rolled copper foil. The insulating substrate can be polyimide, polyethylene terephthalate, aramid and polyvinyl chloride. Single-layer FPC can be divided into the following four subcategories:

1. Single-sided connection without covering layer: The wire pattern is on the insulating substrate, and the wire surface has no covering layer. The interconnection is realized by soldering, fusion welding or pressure welding, which is commonly used in early telephones.

2. Single-sided connection with a covering layer: Compared with the former type, there is only one more covering layer on the surface of the wire. When covering, the pads need to be exposed, and the end area can be simply not covered. It is one of the most widely used single-sided flexible PCBs and is used in automotive instruments and electronic instruments.

3. Double-sided connection without covering layer: the connection pad interface can be connected on the front and back of the wire, and a via hole is opened on the insulating substrate at the pad. Punching, etching or other mechanical methods.

4. Double-sided connection with cover layer: The difference between the former types is that there is a cover layer on the surface, and the cover layer has via holes, allowing both sides to be terminated and still maintaining the cover layer. It consists of two layers of insulating material and a layer of metal conductors. production.

Double-sided FPC has a conductive pattern etched on both sides of the insulating base film, which increases the wiring density per unit area. The metallized hole connects the patterns on both sides of the insulating material to form a conductive path to meet the flexible design and use function. The cover film protects single and double-sided conductors and indicates where the components are placed. According to the needs, metallized holes and cover layers are optional, and this type of FPC is less used.

Multilayer FPC is to laminate 3 or more layers of single-sided or double-sided flexible circuits together, form metallized holes by drilling and electroplating, and form conductive paths between different layers. In this way, no complicated welding process is required. Multilayer circuits have huge functional differences in higher reliability, better thermal conductivity, and easier assembly performance.

The advantage is that the substrate film is lightweight and has excellent electrical properties, such as a low dielectric constant. The

multi-layer flexible PCB board made of polyimide film is about 1/3 lighter than the rigid epoxy glass cloth multi-layer PCB board, but it loses the advantages of single-sided and

double-sided flexible PCB. flexibility, most of these products do not require flexibility. Multilayer FPC can be further divided into the following types:

1. Finished products of flexible insulating substrates: This category is manufactured on flexible insulating substrates, and the finished products are specified to be flexible. This kind of structure usually bonds the two sides of many single-sided or double-sided microstrip flexible PCBs together, but the central part is not bonded together, so it has a high degree of flexibility. For a high degree of flexibility, a thin, suitable coating, such as polyimide, can be used on the conductor layer instead of a thicker laminated cover.

2. Finished products of soft insulating substrates: This category is manufactured on soft insulating substrates, and the finished products are not required to be flexed. This type of multilayer FPC is made of a flexible insulating material, such as a polyimide film, laminated into a multi-layer board, which loses its inherent flexibility after lamination.

In recent years, the market prospect analysis and development trend of China's FPC (flexible circuit board) industry predicts that FPC will continue to innovate in four aspects in the future, mainly in:

1. Thickness: The thickness of FPC must be more flexible and thinner.

2. Folding resistance: The ability to bend is an inherent characteristic of FPC. In the future, the folding resistance of FPC must be stronger and must exceed 10,000 times. Of course, this requires a better substrate.

3. Price: At this stage, the price of FPC is much higher than that of PCB. If the price of FPC comes down, the market will definitely be much wider.

4. Process level: In order to meet various requirements, the process of FPC must be upgraded, and the minimum aperture and minimum line width/line spacing must meet higher requirements.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com