What's the Key Materials for High-Frequency PCB Circuit Boards

The circuit material of a printed circuit board (PCB) is a key building block for RF/microwave circuits - essentially the starting point for these circuits. PCB materials come in many different forms, and the choice of material depends largely on the requirements of the intended application. For example, materials that reliably support high-frequency circuits in commercial wireless products can fail rapidly when exposed to the extremes of a military environment. A basic understanding of PCB material types and their parameters can help match materials to applications.

As with many RF/Microwave components, PCB materials are classified and compared by a number of key parameters, including relative permittivity (Dk or εr), dissipation factor (Df), coefficient of thermal expansion (CTE), dielectric thermal coefficient constant ( TCDk) and thermal conductivity. When classifying different PCB materials, many circuit designers start with Dk. The Dk value of a PCB material refers to the capacitance or energy available between a pair of very close conductors fabricated on the material compared to the same pair of conductors in a vacuum.

A vacuum creates a reference of 1.0, other dielectric materials provide higher references. For example, commercial PCB materials typically have Dk values in the range of about 2 to 10, depending on how they are measured and how often they are tested. Conductors on materials with higher Dk values can store more energy than conductors on materials with lower Dk values.

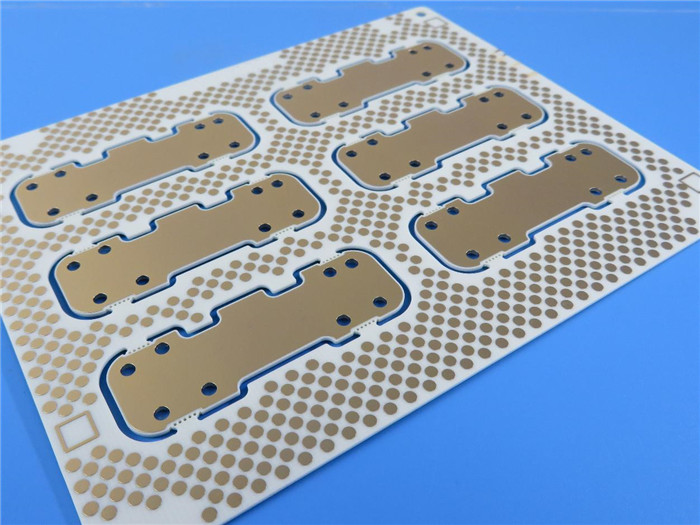

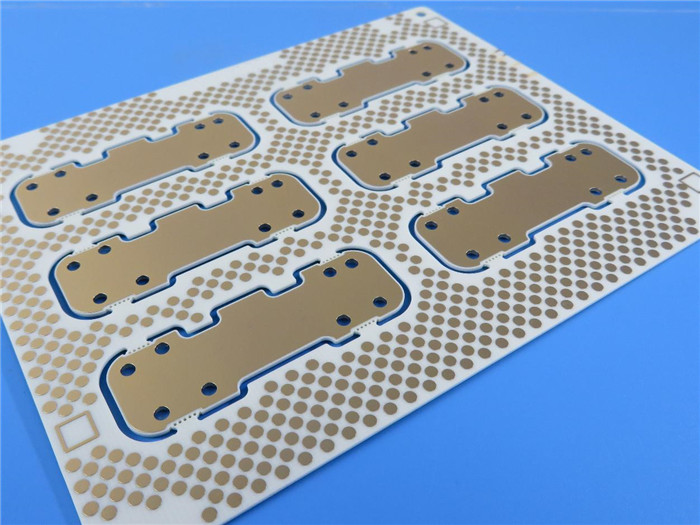

Printed Circuit Board (PCB)

The Dk value of a PCB material affects the size, wavelength, and characteristic impedance of transmission lines fabricated on that material. For example, for a given characteristic impedance and wavelength, the dimensions of a transmission line fabricated on a PCB material with a high Dk value will be much smaller than a transmission line fabricated on a PCB material with a lower Dk value, although other material parameters may vary . Designers facing circuits where loss is a critical performance parameter often prefer to use PCB materials with lower Dk values because these materials have lower losses than materials with higher Dk values.

In practice, PCB materials can lose signal power in four ways: dielectric loss, conductor loss, leakage loss, and radiation loss, although both dielectric and conductor losses can be better controlled through the choice of PCB material. For example, the Df parameter provides a way to compare the dielectric loss of different materials, where a lower Df value indicates a material with lower dielectric loss.

For a given transmission line impedance (e.g. 50Ω), the transmission line on the

low Dk material will be physically wider than the transmission line on the high Dk material, and the conductor loss of the wider transmission line will be smaller. These wider transmission lines also translate into higher manufacturing yields (and savings in production costs) compared to narrower transmission lines for higher Dk materials. However, the trade-off is that they occupy a larger area on the PCB, which can be an issue for designs where miniaturization is critical. The thickness of the PCB substrate, especially its copper conductor layer, also affects the impedance of the transmission line, with thinner dielectric materials and conductors resulting in narrower conductor widths to maintain the desired characteristic impedance.

Conductors of PCB material are usually specified in terms of copper weight, such as 1 oz. (35 microns thick) copper or 2 oz. (70µm thick) copper. The quality of these copper conductors also affects conductor losses. A copper conductor with a rough surface will exhibit higher conductor losses than a copper conductor with a smooth surface profile.

Maintaining transmission line impedance is critical for many RF/microwave circuits, so keeping Dk within a narrow range across the PCB and changing with temperature is critical to achieving tight impedance in your design. Most PCB datasheets show the Dk of the material and its Dk tolerance, such as ±0.5.

Another important material parameter, TCDk, provides detailed information about how much the Dk of the PCB material changes over the operating temperature range, as this also affects the impedance of the transmission line. A TCDk value of 150 ppm/°C may be considered a high value, while a TCDk value of 30 ppm/°C or lower is considered low. For circuits that must maintain impedance over a wide operating temperature range, it is best to use PCB materials with lower TCDk values.

In addition to temperature changes affecting Dk and impedance, they also have mechanical effects on the PCB. The CTE of a PCB is a parameter that attempts to show the effect of temperature on a PCB material. Essentially, it is a measure of the expansion/contraction of a material with temperature, and lower values are the goal. For example, although pure PTFE has a high CTE (about 300 ppm/°C), materials such as polytetrafluoroethylene (PTFE) have long been used in high-frequency PCBs due to their excellent electrical properties.

Some PCB material manufacturers (e.g. use PTFE in their material but add different filler materials to lower the CTE value (see photo). It is worth noting that the CTE of the PCB dielectric material should be close to the CTE of its conductors and other layers matched to minimize the mechanical effects of temperature changes.

PTFE composite

RT/duroid 6035HTC material

This ceramic filled PTFE RT/duroid 6035HTC composite has high thermal conductivity for high power circuit applications

For any commercial PCB material, separate CTE values are usually listed for all three axes (x, y, and z). CTE provides some evidence of how PCB materials handle extreme temperatures, such as during soldering. For example, mismatches in the CTE values of materials used in multilayer structures can lead to reliability issues as the dimensions of different circuit layers change with temperature. PCB materials with lower CTE values are generally considered to be more thermally stable than materials with higher CTE values. For use over a wide temperature range, circuit materials with a CTE of 70 ppm/°C are considered fairly robust and should be able to handle the extreme temperatures of circuit fabrication and assembly.

The CTE of the PCB material should closely match the CTE of copper in the x and y axes to minimize the variation of mechanical stress with temperature. Additionally, the CTE on the z-axis of the circuit material can provide insight into the expected reliability of plated through holes (PTHs) that will be formed through the dielectric material, since these holes are plated with copper. Ideally, the dielectric material and copper will expand and contract with temperature in a similar manner to achieve the high reliability of the PTH.

Heat dissipation of

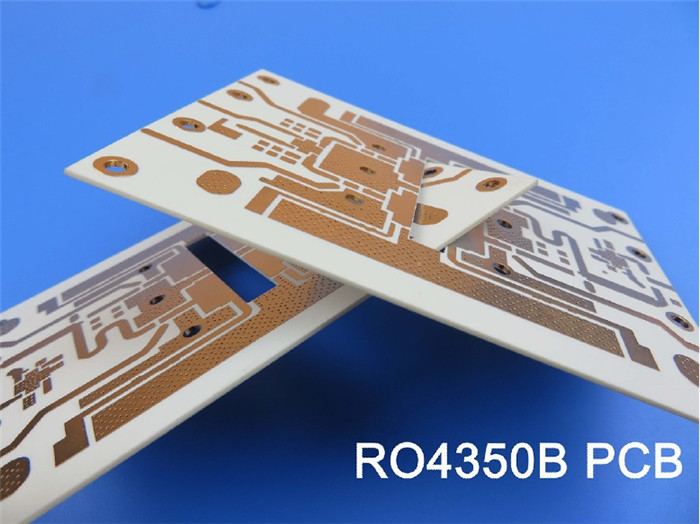

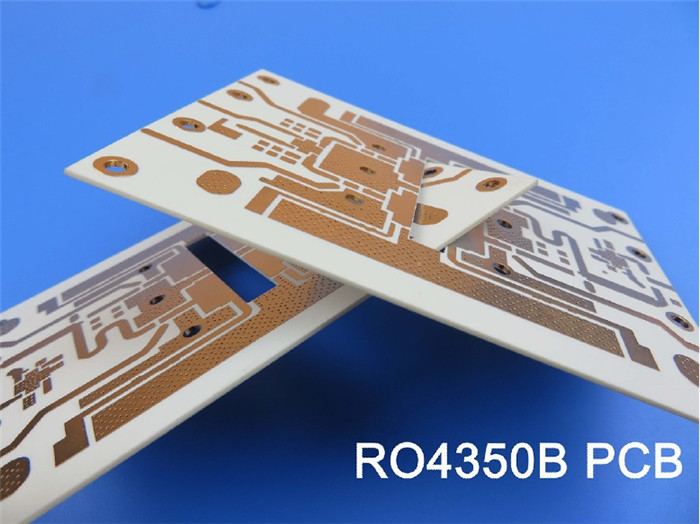

RF microwave circuit board, especially for high power designs, is an important function characterized by the thermal conductivity of the PCB. Although standard PCB materials may have a thermal conductivity of 0.25 W/m/K, fillers are often added to PCB materials to increase thermal conductivity to more favorable values (and better heat dissipation). For example, RO4350B, a hydrocarbon/ceramic PCB material from Rogers Corporation, has long been a reliable building block material for high frequency applications including automotive and cellular communication systems.

The RO4350B material PCB is not PTFE based, but has a relatively low z-axis Dk of 3.48±0.05 at 10 GHz, a TCDk of +50 pm/°C, and a dissipation factor of 0.0037. It has a reasonably good thermal conductivity of 0.69 W/m/K. In contrast, RT/duroid 6035HTC, also from Rogers Corporation, is a ceramic-filled PTFE composite specially formulated for high power, high frequency circuits with a Dk of 3.50±0.05 and a TCDk of +50 ppm/°C. , and has a low loss factor of 0.0013. It has excellent thermal conductivity with a typical value of 1.44W/m/K.

RF Microwave PCB

From

low-cost FR-4 materials to expensive

PTFE-based materials, a wide variety of materials are used for RF/Microwave PCBs. A circuit board composed of FR-4 material is essentially a laminate of glass-reinforced epoxy, while PTFE material is usually reinforced with glass fiber or ceramic filler material (although pure PTFE-based PCBs are also used). The difference in performance between these two extreme materials points to the trade-offs that PCB materials must make between cost and performance and between the ease of processing of FR-4 and the processing difficulty of

PTFE materials.

Excellent circuit performance often comes at a high price, although many PCB material suppliers have put significant effort into developing a variety of composite materials with varying Dk values for various RF/microwave applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com