A

PCB user generally needs to present all of the primary manufacturing data in a

complete and unambiguous way that the PCB manufacturer can quote and produce

the boards without error.

A

checklist is listed as follows. Some parameters not necessary for a particular

job can be deleted so that the specification form only reflects the relevant

data.

(1)Company

name

(2)Part

number

(3)Lot

size and annual requirements

(4)Layer

count

(5)Board

size

(6)Board

thickness

(7)Board

shape

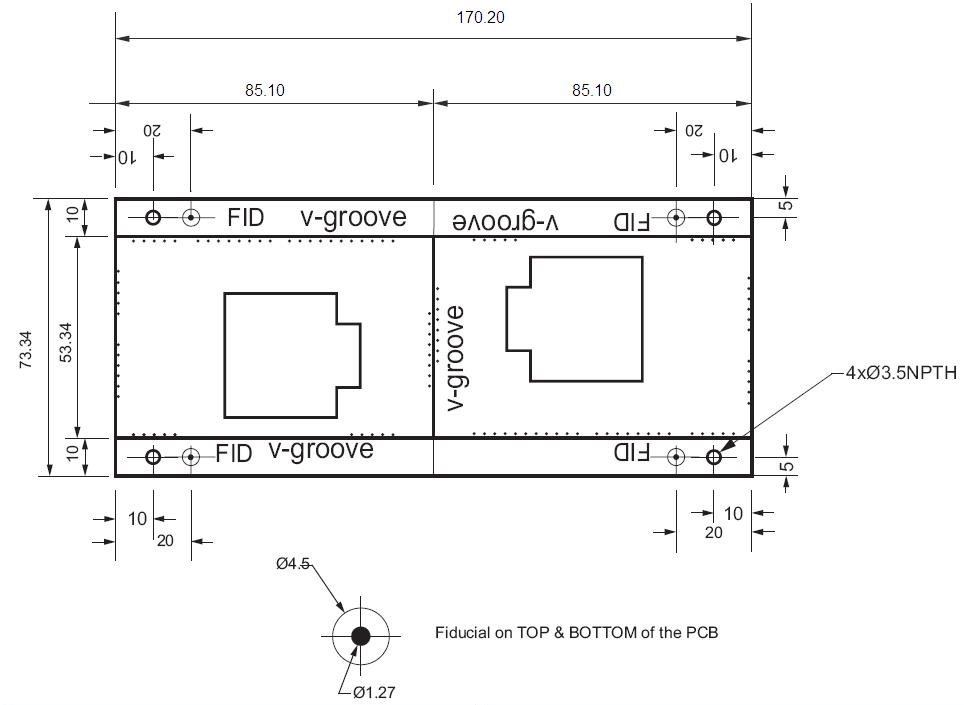

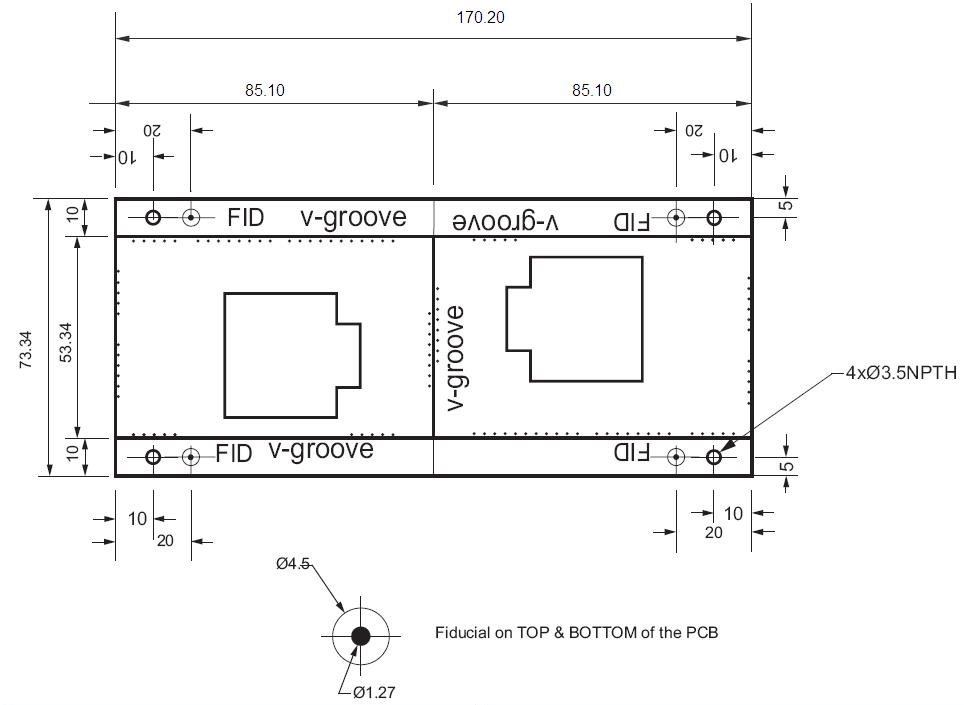

(8)Panelization

(9)Board

build-up

(10)Boards

with controlled impedance

(11)Test

coupon

(12)Machining

(Contouring)

(13)Laminate

type and UL flammability

(14)Warp

& Twist

(15)Outer

layers

(16)Inner

layers

(17)Solderability

preservation

(18)Solder

masks

(19)Notation

(20)Peelable

solder mask

(21)Carbon

printing

(22)Plated

through holes (PTHs)

(23)Non-PTHs

(24)Milled

Holes (Slots)

(25)

Blind via holes

(26)

Buried via holes

(27)Board

tooling holes

(28)Panel

tooling holes

(29)Board

mounting

(30)Edge

connectors

(31)Soldering

conditions

(32)Markings

(33)Electrical

test

(34)Automatic

optical inspection

(35)Minimum

pattern conditions

(36)Quality

conditions

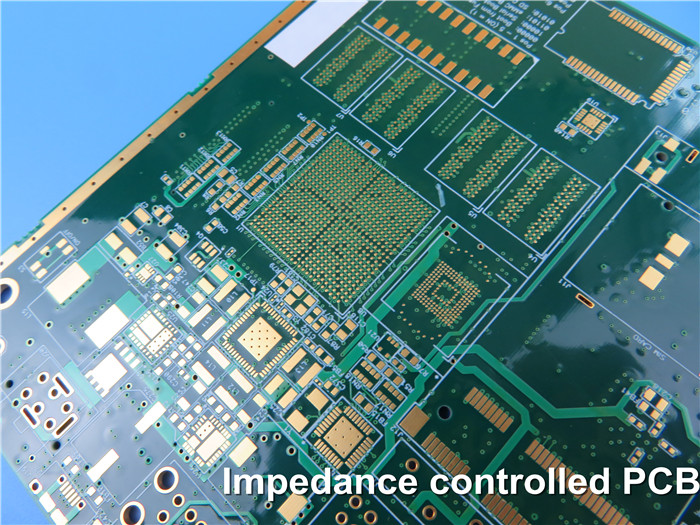

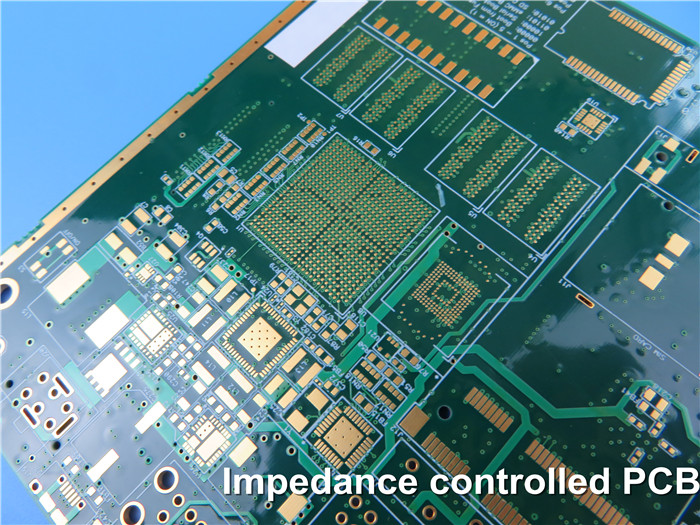

A view of PCB

panelization

To

know a basic situation of one PCB, these 7 points have to be taken into

consideration:

(1) Laminate type (base material)

(2) Layer count

(3) Board size

(4) Board thickness

(5) Copper weight

(6) The color of solder mask and silkscreen

(7) Surface finish

Is

it much simple now?

If

you have any enquiries, please feel free to contact us. Welcome your patronage.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com