PCB accelerates upward breakthrough, high-end products are shining

According to Prismark's forecast, the PCB industry is expected to grow at a growth rate of 8.6% in 2021, and will grow at a compound annual growth rate of 5.8% between 2020 and 2025. By 2025, the global PCB industry output value will reach 86.33 billion US dollars.

With the continuous development of science and technology, new technologies and new applications such as 5G communication, cloud computing, big data, artificial intelligence, Internet of Things, and electric vehicles continue to emerge, and the demand for PCBs is also increasing. It is worth noting that although my country is a big manufacturing country and there are many PCB companies, the product homogeneity is relatively serious, and it is excessively concentrated on low-end PCBs with cost advantages, traditional products such as single-layer/double-layer boards and multi-layer boards. In terms of high-end PCBs, the proportion of high-end PCBs is still relatively low, especially in terms of packaging substrates, high-end HDI boards, and multi-layer boards.

At present, the market demand for high-end PCB boards has exploded rapidly, but the output of production capacity has increased slowly, resulting in a large gap between market demand and supply. With the continuous improvement and gradual optimization of China's PCB manufacturing technology, the market share of traditional

single/double-sided PCB and

multi-layer PCB has gradually declined, while the market share of high-tech and high-value-added PCB boards has continued to rise. Faced with the constant iteration and update of market demand, many PCB companies have begun to move towards the high-end PCB field with higher technical thresholds and greater capital investment. Although some technologies or production capacity are lagging behind, the market competition in the PCB industry is still fierce.

The supply of high-end PCB market is still dominated by foreign manufacturers. Due to the imperfect supporting facilities around domestic PCBs, some key PCB-specific materials, high-end equipment and engineering software are dependent on imports. With the step-by-step breakthrough of domestic manufacturing technology, the relevant supply chain will also achieve good growth. Domestic PCB enterprises will gradually grow up, develop independent innovation technologies and equipment, and respond to the rapidly changing needs of the market.

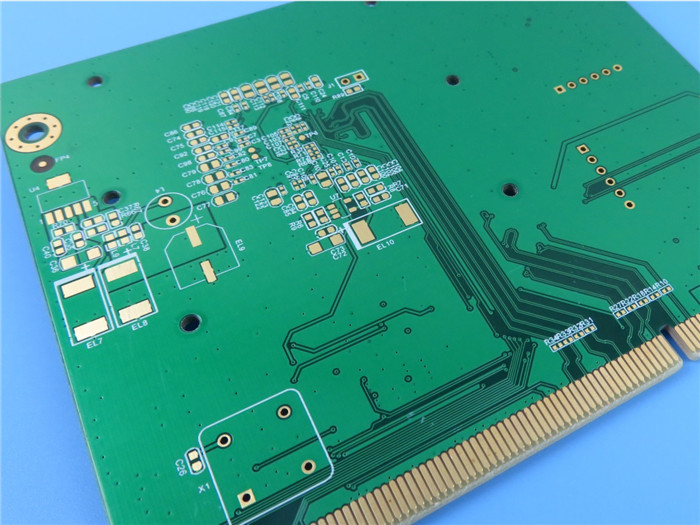

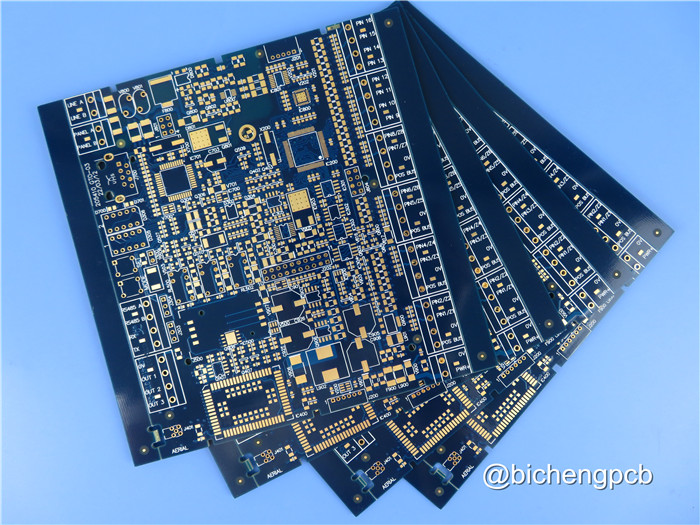

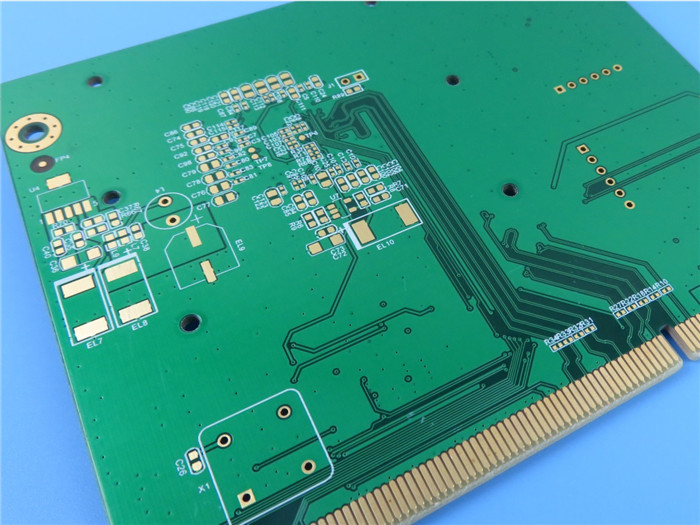

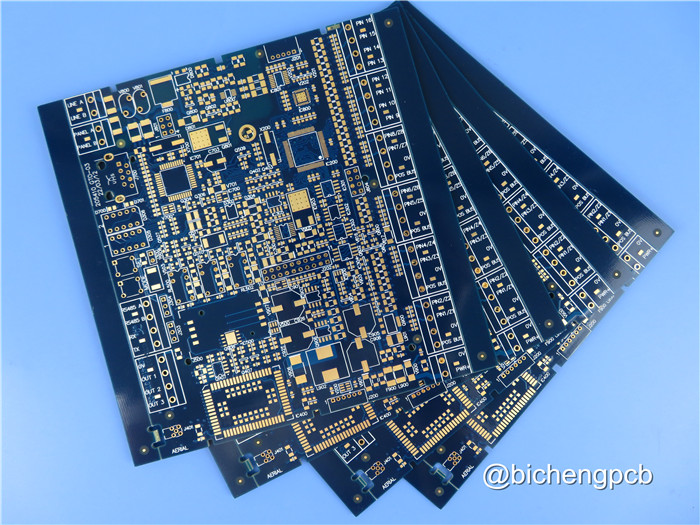

When the domestic PCB industry is booming, domestic PCB manufacturers have vigorously increased their high-end board business. On the one hand, they have the opportunity to escape from the low-end PCB Red Sea market, and on the other hand, they also have the opportunity to grow together with the domestic high-end industry. , to achieve a double breakthrough in technology and performance. With the market, high-end PCB products have higher requirements in terms of

high-speed pcb material application, processing density and design layers. The number of layers, high aspect ratio and small hole spacing make processing difficult, and require more advanced and ultra-high technology. , the engineering team has strong expertise in the testing field to ensure product reliability. While expanding production, PCB enterprises should pay more attention to improving product performance and quality, and develop towards production automation, precision, multi-function and modern equipment.

In order to better grasp the opportunities for industry development and quickly respond to changes in high-end PCB market demand, the Maker Factory will continue to increase its focus on high-level multi-layer circuit boards, high-frequency/high-speed boards,

HDI boards, metal substrates, thick copper power boards, and

rigid-flex PCB board. The input and layout of products such as boards. Based on strong production capacity and production process equipment, senior R&D team and innovative technology, we create high-density, high-multi-layer, high-difficulty, high-tech, and high-reliability PCB boards. customer request.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com