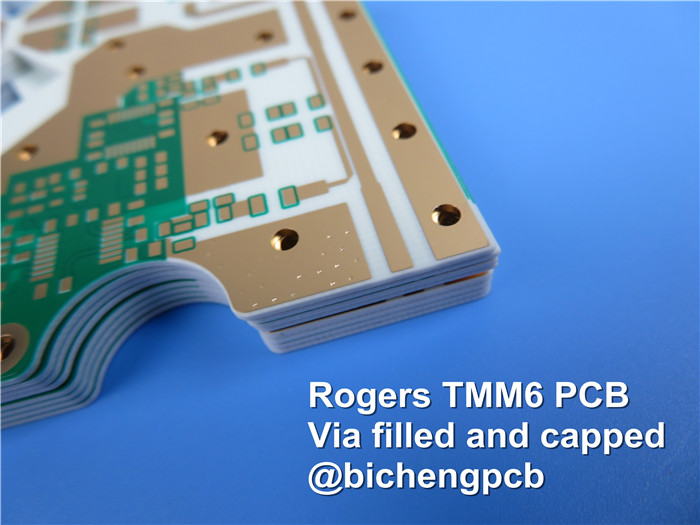

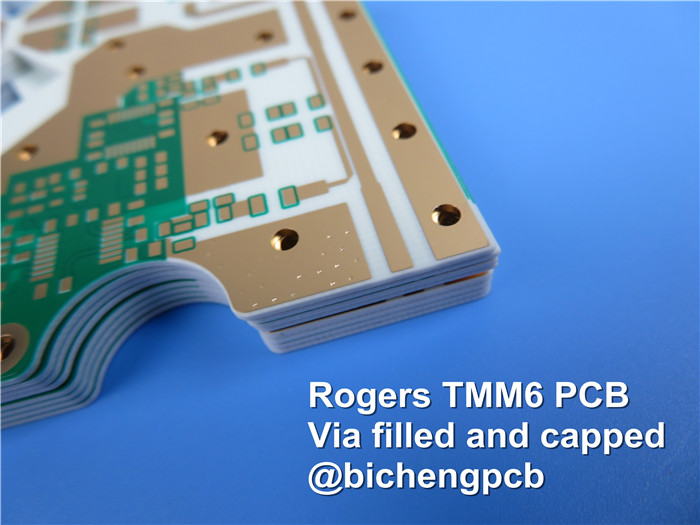

Rogers TMM Series PCB: TMM 3, TMM 4, TMM 6, and TMM 10

Rogers TMM thermoset microwave materials are composites of hydrocarbon ceramics and thermoset polymers designed specifically for strip-line and microstrip applications. TMM is available in a variety of claddings and dielectric constants. TMM laminates have mechanical and electrical properties that make them suitable for a variety of applications.

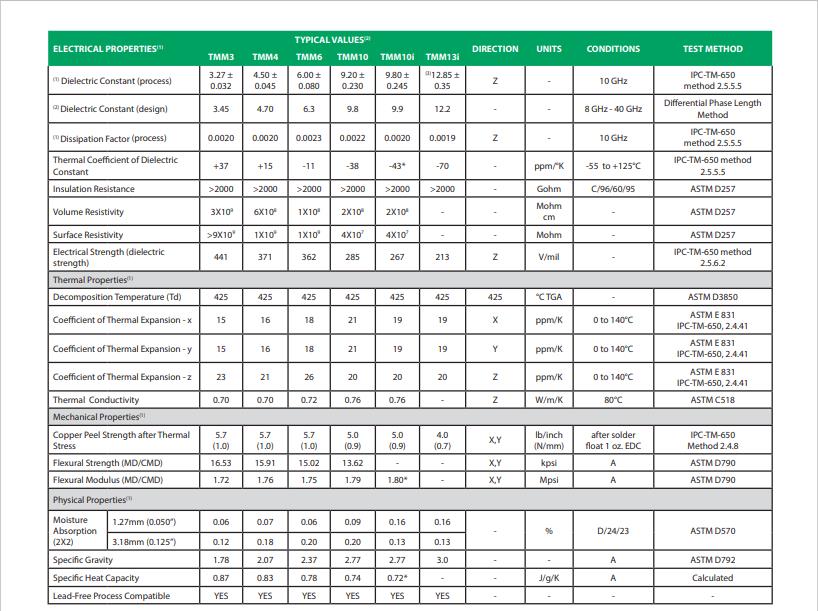

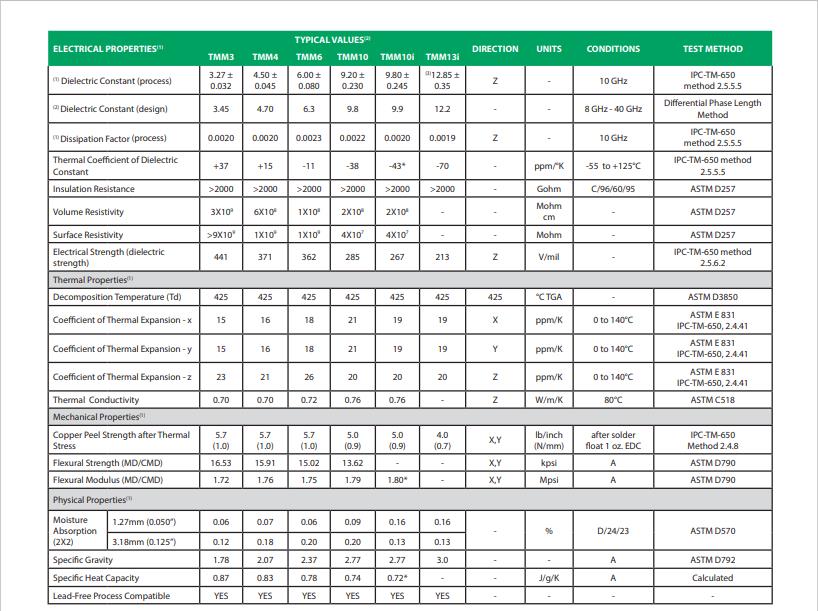

TMM has a very good thermal expansion coefficient, a slow thermal change of the dielectric constant (Dk), and a stable dielectric constant. Greater copper coating specifications are available from TMM. These laminates possess the qualities of both ceramic and PTFE microwave circuit laminates without requiring the manufacturing processes for those materials.

TMM is distinct from other laminates in that it does not require sodium napthanate treatment prior to electroless plating. TMM laminates have an extremely low thermal coefficient of Dk, which is usually less than 30 ppm/°C, which is one of their most amazing properties.

TMM laminates are based on thermoset resins, and do not soften when heated. As a result, wire bonding of component leads to circuit traces can be performed without concerns of pad lifting or substrate deformation.

TMM laminates combine many of the desirable features of ceramic substrates with the ease of soft substrate processing techniques. Substrate thicknesses of 0.015” to 0.500” are available. The base substrate is resistant to etchants and solvents used in printed circuit production. Consequently, all common PWB processes can be used to produce TMM thermoset microwave materials

The Benefits of Rogers TMM

TMM laminates from Rogers are high-quality microwave materials with excellent electrical and mechanical properties. These materials bring together the advantages of PTFE microwave circuits and ceramic laminates.

Rogers TMM laminates have exceptional mechanical properties because they resist cold and creep flow, making them mechanically reliable and stable.

Chemical reagent resistance: Rogers TMM laminates are chemical reagent resistant, which helps to ensure that there is no damage during the placement and production process. After being exposed to chemical reagents for a set period of time, these microwave materials retain their original properties.

Rogers TMM laminates are made of thermosetting resin, which ensures good wire bonding. These materials can withstand any temperature, including extreme heat.

Absorption of moisture: These laminates can endure in a humid setting. Rogers TMM is a good material for a setting with high levels of humidity because it can absorb moisture from its surroundings.

The laminate known as Rogers TMM is made of ceramics, hydrocarbons, and thermosetting polymers. Comparing these laminates to some alumina filler substrates reveals processing advantages. Rogers TMM laminates come in a variety of thicknesses, including TMM 10, TMM 6, TMM 4, etc., but they all share a number of characteristics.

The mechanical and electrical characteristics of these microwave materials make them suitable in a variety of applications. Not only are Rogers TMM laminates appropriate for microstrip applications, but they are also highly reliable for stripline applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com