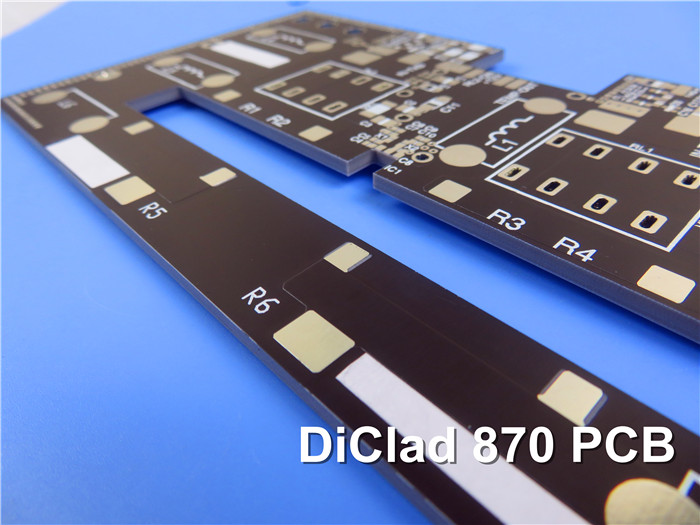

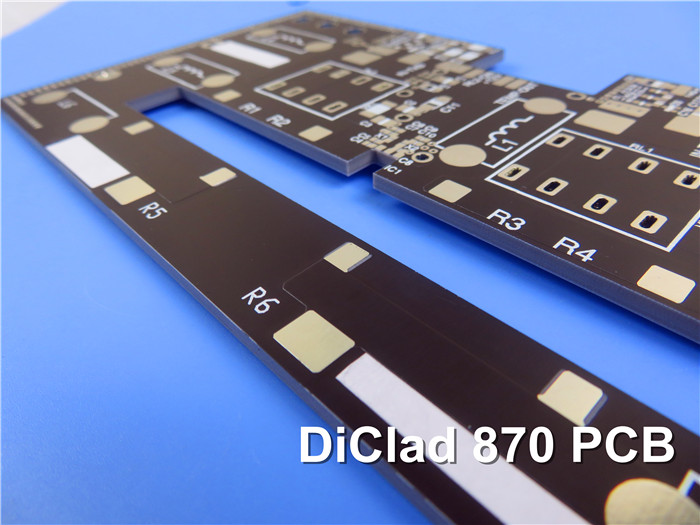

The Advantages of Rogers DiClad 870/880 Series Laminates

The Rogers DiClad 870 and 880 series laminates have low dielectric constant values, low moisture absorption, and a unique routing design. The two-layer, woven PTFE laminates are also available in 48′′ x 54′′ sizes. They are ideal for PCB applications that require high frequency and registration stability. Continue reading to learn more.

Low-density woven-fiberglass composites reinforced with woven fiberglass are used in both the

DiClad 870 laminates. These materials are excellent for high-frequency PCB applications that require low dielectric constants as well as improved registration and dimensional stability. TMM and IsoClad laminates are also available from Rogers for a more reliable and complex routing process.

Rogers PCB materials, in addition to their unique routing design, are critical in a variety of technologies. The most recent advances in semiconductor technology have enabled signal processing at higher frequencies. The high-frequency Rogers laminate is ideal for digital PCB applications that require 10 GHz performance. FR-4 materials may also be required for high-frequency PCB applications.

Rogers DiClad laminates are the best choice for high-frequency PCB designs.

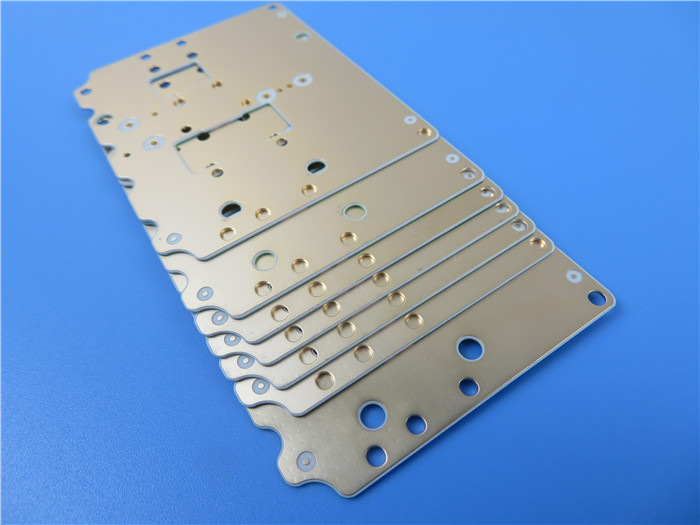

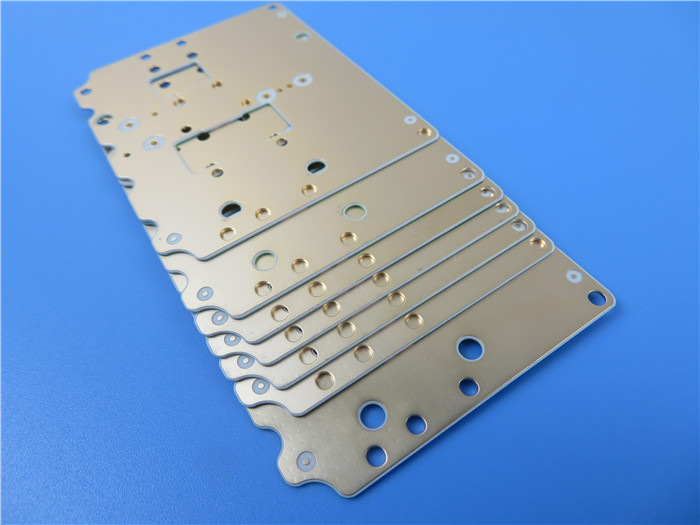

When determining the proper thickness for your PCB, consider how many circuits your design requires. Naturally, the more layers there are, the higher the overall cost. However, keep in mind that custom designs may necessitate specialized skills. Furthermore, these custom designs may necessitate the use of specialized equipment or tools. Once you've determined the thickness you require, you can choose the best substrate for your needs.

The dissipation factor, or Dk, of Rogers DiClad 870/881 laminates is lower than that of other materials on the market. These materials have higher thermal conductivity than traditional PTFE laminates and are suitable for multilayer PCBs. In the PCB semiconductor industry, they also have the highest embedded resistor constancy.

Rogers DiClaD 870/880 laminates have a dielectric constant of 2.60 nm. Microwave and millimeter-wave applications are possible with these materials. The thin metal cladding used in these laminates contributes to their thermal stability. Furthermore, the materials can be used with standard PTFE-based printed circuit board substrates. These materials are ideal for use on high-reliability printed circuit boards.

Rogers DiClad 870/80 material's electrical properties are critical in high-frequency PCB design. High-frequency laminates are required for high-frequency PCB applications. The dielectric constant quantifies a material's ability to store electrical charge. The greater the dielectric constant, the greater the benefit. Rogers DiClad 870/880 material has a lower dielectric constant, which means less signal loss in high-frequency PCB applications.

Rogers DiClad 880 and 850 laminates' thermal stability is critical to their application. It must be able to withstand a wide temperature range when used in electronics. FR-4 laminates, for example, exhibit significant temperature variations (Td), whereas Rogers DiClad 870/880 laminates exhibit no temperature variation. As a result, high-frequency Rogers laminates are extremely popular.

For high-frequency PCB applications, a variety of materials are available. The RO4000 and

TMM laminates lack heavy metal cladding. Thick metal cladding comes in a variety of thicknesses. Some types are compatible with the low-temperature material FR-4. Copper foil works well with FR-4 and DiClad 870/880 laminates.

It is critical in high-frequency PCB applications to match the dielectric constant of a Rogers material with that of the substrate. If the two materials are incompatible, it can lead to a weakened solder joint or PCB delamination. Other materials requiring different fabrication processes are compatible with Rogers DiClad 870/880 PCBs.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com