When selecting high frequency and high speed materials for PCB used in

high frequency circuits, the DK value of PCB materials and their variation characteristics at different frequencies should be taken into account. DF and its performance under frequency, temperature, and humidity conditions will be investigated for requirements that focus on high-speed signal transmission or characteristic impedance control.

In general, high-frequency and high-speed materials exhibit the law of large changes in DK and DF values as frequency changes. Their DK and DF values change more noticeably in the frequency range from 1 MHz to 1 GHz. For example, the DK value of general epoxy resin-glass fiber cloth based substrate material general FR-4 substrates is 4.7 at lMHz, but it changes to 4.19 at lGHz. Its DK value changes slowly above lGHz. The change trend is decreasing as the frequency increases, but the change range is not large. At l0GHz, for example, the DK value of FR-4 is typically 4.15. The DK value of substrate materials with high speed and high frequency properties varies slightly with frequency. DK mostly stays within the 0.02 range as the frequency changes from lMHz to lGHz. Its DK value has a slight downward trend as frequency increases from low to high.

Because of the influence of frequency changes, the dielectric loss factor DF of high frequency materials and high speed materials changes more than DK. Its change rule is increasing. As a result, when evaluating a substrate material's high-frequency characteristics, the focus of its investigation is its DF value change. There are two distinct types of common substrate materials that have high speed and high frequency characteristics. One advantage is that its DF value varies very little with frequency. In the range of change, another type is similar to the general substrate material, but its DF value is low.

How to Choose High-Frequency and High-Speed Materials?

PCB material selection must strike a balance between meeting design requirements, mass production, and cost. Design requirements, in short, include electrical and structural reliability. When designing a very high-speed PCB with a frequency greater than GHz, the PCB material issue usually takes precedence. The current FR-4 material, for example, has a high dielectric loss at several GHz frequencies, which may be inapplicable.

What are the high-frequency and high-speed PCB materials?

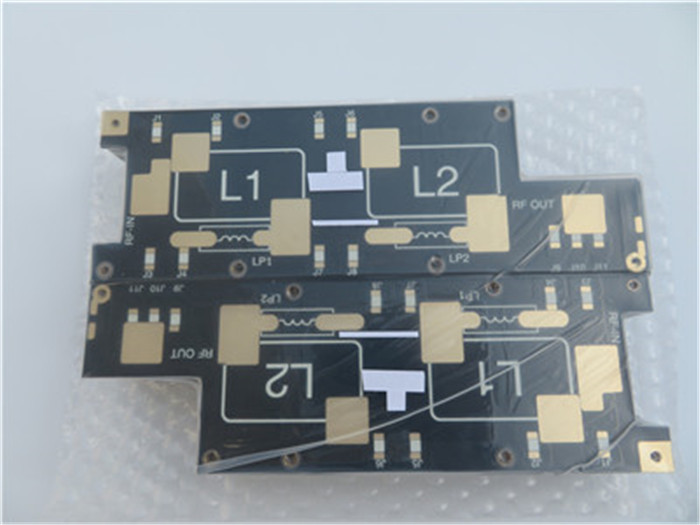

For example, a 10Gb/S high-speed digital signal is a square wave, which can be thought of as a superposition of sine wave signals of varying frequencies. As a result, 10Gb/S contains a wide range of frequency signals. 5GHz fundamental signal, 3rd order 15GHz signal, 5th order 25GHz signal, 7th order 35GHz signal, and so on. The digital signal's integrity and the steepness of the upper and lower edges are the same as the high-frequency harmonic part of the RF microwave digital signal, which achieves low loss and low distortion transmission in the microwave frequency band. As a result, in many ways, the material selection for high-speed circuit PCBs like M6 high speed PCB is similar to that of RF and microwave circuits.

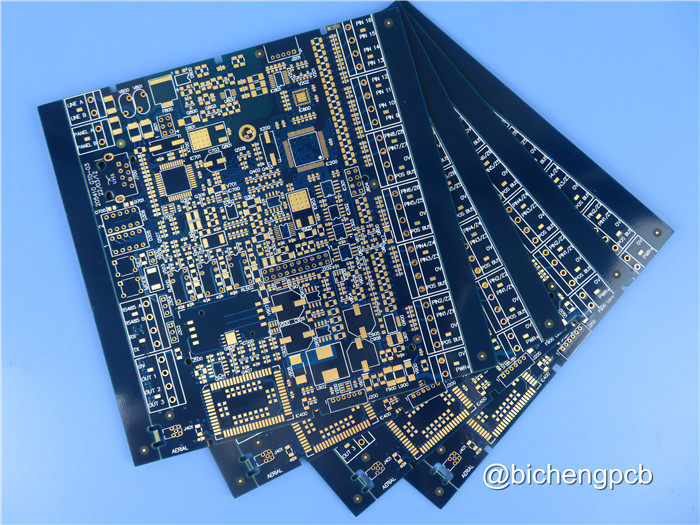

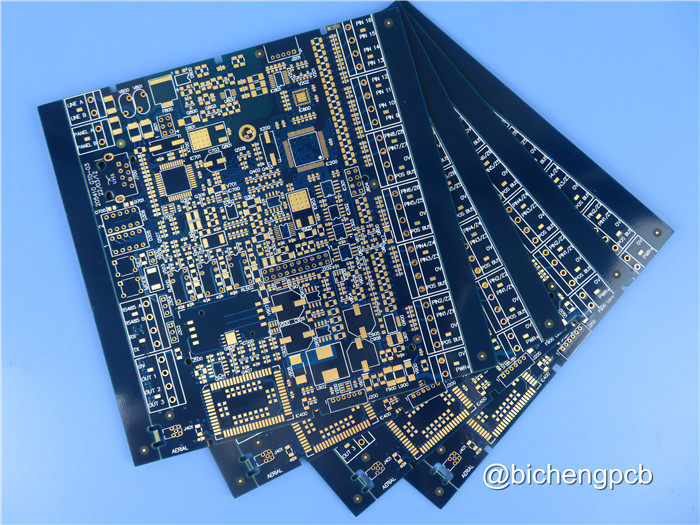

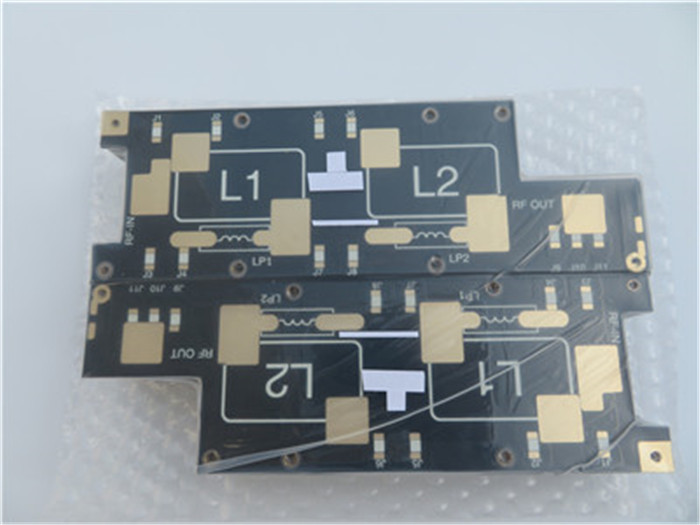

In actual engineering operations, the selection of high-frequency material such as

F4B high frequency PCB and high-speed materials appears straightforward, but there are numerous factors to consider. As a PCB design engineer or high-speed project leader, I gained an understanding of plate characteristics and selection through the introduction of this article. Understand sheet metal's electrical properties, thermal properties, reliability, and so on. And use the stack wisely to create a product with high reliability and good processability, as well as to optimize the consideration of various factors.

The following will introduce the main considerations for selecting appropriate high-frequency materials and high-speed materials.

1. The manufacturability of PCB.

For example, how about multiple pressing performance, temperature performance, CAF/heat resistance, mechanical toughness, good reliability and fire rating.

2. PCB and product matching performance, such as electrical, performance stability, etc.

Low loss, stable Dk/Df parameter, low dispersion, small coefficient of variation with frequency and environment, small tolerance of material thickness and glue content, good impedance control; consider low roughness copper foil if the wiring is long. Furthermore, high-speed circuit design necessitates simulation early on, and the simulation results serve as the design reference standard. "Xingsen Technology-Agilent High-speed/RF Joint Laboratory" has solved the performance problem of inconsistency between simulation results and testing, and has performed extensive closed-loop verification of simulation and actual testing, and can achieve consistency between simulation and actual measurement using novel methods.

3. Timely availability of PCB materials.

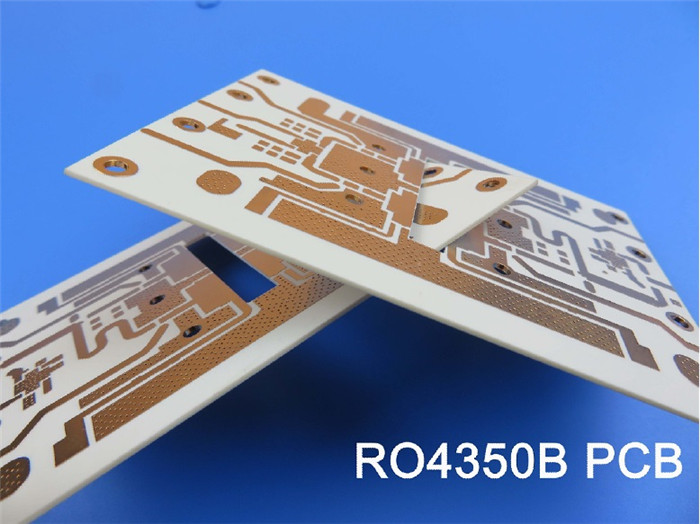

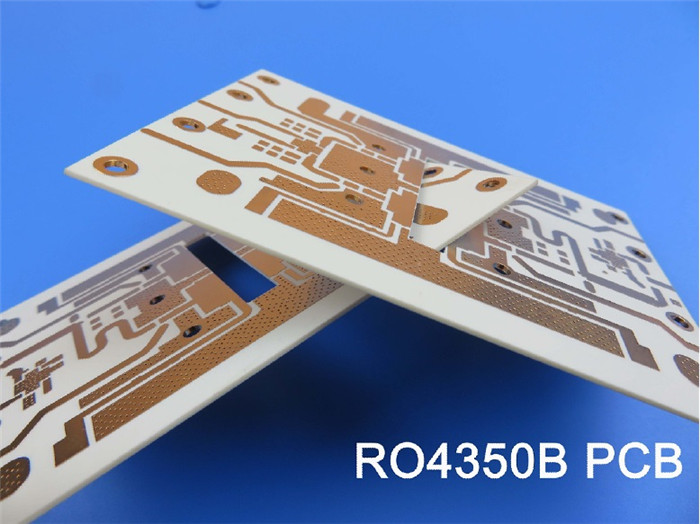

Many high-frequency and high-speed materials have a very long procurement cycle, even up to 2-3 months. Customers must supply many high-frequency plates in addition to the standard

Rogers 4350b RFT foil PCB in stock. As a result, high-frequency plates must be communicated with the manufacturer in advance in order to prepare materials as soon as possible.

4. Cost factors of high-frequency materials and high-speed materials.

It depends on the price sensitivity of the product, whether it is a consumer product or a communication, medical, industrial and military application.

5. Applicability of laws and regulations, etc.

To meet RoHS and halogen-free requirements, it should be integrated with environmental protection regulations from various countries.

The operation speed of a high-speed digital circuit is the most important factor in PCB selection. The lower the Df value of the chosen PCB, the higher the circuit speed. Medium and low loss circuit boards will be suitable for 10Gb/S digital circuits. The plate with the lowest loss is appropriate for a 25Gb/s digital circuit. The ultra-low loss board will adapt to faster high-speed digital circuits, with a speed of 50Gb/s or higher.

Considering the Df of high-frequency materials and high-speed materials

Df between 0.01-0.005 circuit board is suitable for 10Gb/S digital circuit.

The circuit board with Df between 0.005-0.003 is suitable for digital circuits with an upper limit of 25Gb/S.

The circuit board with Df no more than 0.0015 is suitable for 50Gb/S or even high-speed digital circuits.

Common high-frequency materials and high-speed materials include.

1. Rogers, RO4003, RO3003, RO4350, RO5880, etc

2. TUC: Tuc862, 872SLK, 883, 933, etc

3. Panasonic, Megtron 4, Megtron 6, etc

4. Isola, 370hr, FR408HR, IS620, IS680, etc

5. Nelco, N4000-13, N4000-13EPSI, etc

6. Dongguan Shengyi, Taizhou Wangling, Taixing Microwave, etc

Of course, there are many other high-frequency board manufacturers, such as Arlon, which Rogers acquired last year, and Taconic, which are all RF microwave board factories with guaranteed performance.

We discuss how to choose high-frequency and high-speed materials, as well as PCB design considerations, in this section. In practical application, you must analyze specific cases.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com