The Deepening Millimeter-Wave Revolution: High-Performance Materials Become the PCB Industry's Watershed

December 19, 2025—As 5G-Advanced smoothly evolves towards 6G and low-earth orbit satellite internet constellations enter a phase of dense deployment, the industry's news focus in the final two months of 2025 has shifted from "whether millimeter-wave technology is needed" to "how to achieve higher-performance, more stable and reliable millimeter-wave hardware." This shift focuses the industry chain's attention on a core link: the high-performance PCB substrates used for millimeter-wave frequency bands and their corresponding processing capabilities. For specialized manufacturers with over twenty years of deep expertise in the high-frequency PCB field, this is precisely the moment when the value of their technological moat becomes clearly evident.

Spotlight: The Dual Challenges of Performance and Supply Chain Security

Recently, several leading communication equipment and satellite manufacturers have indicated in their financial reports and technical forums that the research, development, and mass production of their new-generation millimeter-wave products are facing two specific challenges:

Performance Bottlenecks: As operating frequencies extend to higher bands (such as E-band and beyond), the dielectric loss and stability of traditional high-performance materials are beginning to constrain system link budgets. This imposes Almost rigorous requirements for phase consistency, insertion loss, and temperature stability.

Demand for Supply Chain Diversification: To ensure the delivery security and cost control of critical infrastructure projects, implementing a "multi-source supply" strategy for core raw materials has become an industry consensus. Identifying high-end domestic or regional substrate materials that offer performance comparable to international top-tier brands and stable supply is a joint core mission for both procurement and R&D departments.

Industry Response: The Industrial Application of Next-Generation Materials

The industry's response to these challenges is directly reflected in the rapid validation and adoption of new materials. Recently, a new generation of polytetrafluoroethylene composite materials employing special formulations and processes is gaining widespread attention. Taking theF4BM220 series material from a leading domestic brand as an example, its technical specifications directly target the pain points of millimeter-wave applications:

Exceptionally Stable Electrical Performance: At 10GHz, the dielectric constant (Dk) can be stably controlled at 2.20±0.04, with a dissipation factor (Df) as low as 0.001. This provides superior insertion loss control and phase prediction accuracy for millimeter-wave circuit design.

Outstanding Mechanical and Environmental Stability: The X/Y axis coefficient of thermal expansion (CTE) is as low as 25/34 ppm/°C, and moisture absorption is≤0.08%, significantly improving the reliability of multilayer board structures and performance consistency in complex environments.

Clear Scenario Definition: Through different copper foil combinations (such as standard electrolytic copper and low-roughness reverse-treated copper foil), this material series precisely distinguishes between general high-performance applications and scenarios with stringent requirements for passive intermodulation (PIM), such as large-scale phased array antennas, offering designers flexible and economical choices.

Our Practice: From Material Certification to Manufacturing Implementation

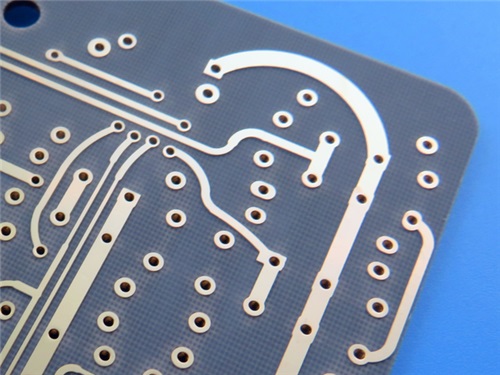

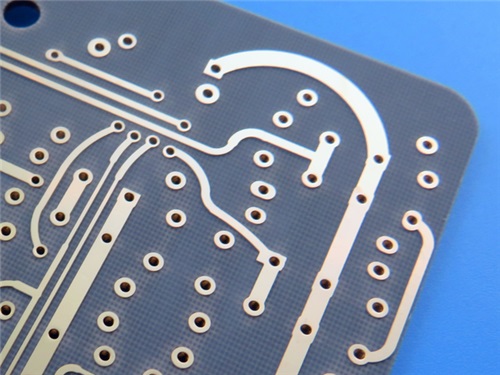

In response to this industry trend, leveraging our long-term process accumulation in the high-frequency field, we have rapidly completed comprehensive process certification for a new generation of high-performance materials, including Wangling F4BM220. The key to our success lies in resolving a series of difficulties associated with processing such materials, including high-precision trace control, via metallization reliability, and lamination processes. We are capable of reliably providing manufacturing services ranging from simple double-sided boards to complex multilayer boards.

For example, we can now provide customers with a standard 2-layer board solution based on F4BM220 material (Structure: 35μm copper foil - 0.5mm F4BM220 core material - 35μm copper foil). This solution is particularly suitable for applications with extremely high demands for low loss and stability, such as filters, phase shifters, power dividers, and millimeter-wave test modules, and can quickly support prototyping.

Outlook: The Reshaping of Value Through Specialization

The industry dynamics at the end of 2025 clearly reveal that in the millimeter-wave era, PCBs are no longer simple interconnect carriers but are core components directly influencing RF system performance. This requires manufacturers to possess deep material understanding capabilities, precise fabrication processes, and engineering strength for collaborative design with customers.

The ability to rapidly respond to material innovations, transform advanced substrates into stable and reliable circuit board products, and provide full-chain services from design support to batch delivery is becoming the key criterion differentiating ordinary suppliers from strategic partners. For equipment manufacturers committed to achieving leadership in next-generation communication, satellite, and radar fields, choosing a manufacturing partner with long-term accumulation in this specialized area and the ability to keep pace with the technological frontier has become a strategic decision to reduce project risk and accelerate product time-to-market.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com