Rogers RO3035 PCB

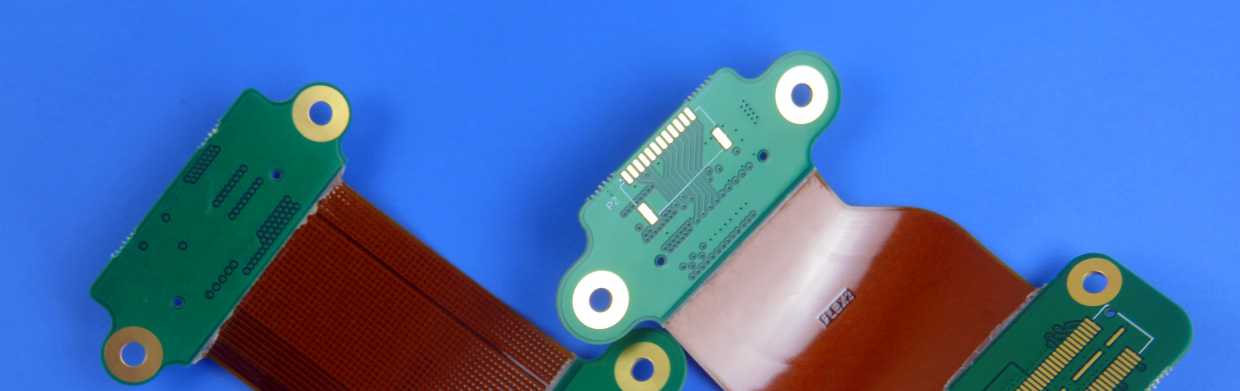

Rogers RO3035 PCBs are ceramic-filled PTFE based high frequency circuit boards. Its expansion coefficient is matched to that of copper, which allows the PCBs to exhibit excellent dimensional stability. RO3035 materials have dielectric constant of 3.50 at 10GHz. With the characteristics of stable DK over different temperature and uniform DK over wide frequency range, it solves many challenges faced by antenna designers, such as patch antennas, phase array antennas. Since its “soft-substrate” feature, it has successful applications in a variety of conformal antennas. RO3035 materials exhibit the CTE in the X and Y axis of 17 and 17 ppm/°C respectively. This expansion coefficient is matched to that of copper (17 ppm/°C), which allows the material to exhibit excellent dimensional stability, with typical etch shrinkage of less than 0.5 mils per inch. The Z-axis CTE is 24 ppm/°C, which provides exceptional plated through-hole reliability, even in severe thermal environments. Low X, Y and Z axis CTE and thermal conductivity of 0.5 W/m/k assure its reliability over power cycling and active electronically scanned array (AESA). Low dissipation factor of .0015 at 10 GHz together with high thermal conductivity is a must for power amplifiers, low noise amplifiers and receivers, digital communications control circuitry etc. RO3035 PCBs also have low moisture absorption of 0.04%, thermal conductivity of 0.5 W/m/K, which benefits for the thermal management. RO3035 PCB can be fabricated using standard PTFE circuit board processing techniques, so it’s suitable for volume manufacturing process to win the market.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com