TMM4 High Frequency PCB

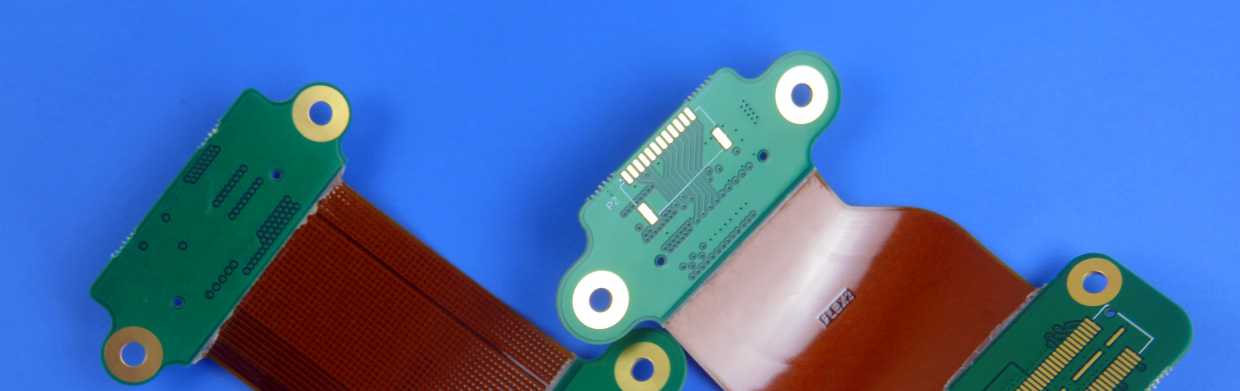

Rogers TMM 4 PCB is a ceramic, hydrocarbon, thermoset polymer composite designed for stripline and microstrip applications. It has strong mechanical and chemical properties combined many of the benefits of both ceramic and traditional PTFE materials. It is based on thermoset resins which allows for reliable wire-bonding without pad lifting or substrate deformation. TMM 4 has dielectric constant value of 4.5 +/- .045 at 10GHz, the tolerance is very tight. Then dissipation factor is .002 at 10GHz, very low dissipation factor. Next, the thermal coefficient of dielectric constant (TCDK) is as low as 15 ppm/°C from -55°C to +125°C. Ideally, TCDk should be 0 ppm / ℃, that is, Dk does not change with temperature. So, as a digital reference, a TCDk less than | 50 | ppm / ℃ or lower can be considered better. The coefficient of thermal expansion of three axes (16,16 and 21 ppm/°C) is very closely matched to copper, so TMM4 PCB production has very high reliable plated through holes and low etch shrinkage values. For TMM 4 PCBs, we can provide you with single layer board, double layer board, multi-layer board and hybrid types. TMM 4 PCBs have wide thickness. There are the standard thickness such as 20 mils, 30 mils, 50 mils and 60mils etc. and non-standard thickness such as 15 mils, 25 mils,75 mils, and 125 mils etc. It’s as thin as 15 mils and as thick as 500 mils for our designers. Finished copper on PCB can be 1oz, 2oz and 3oz. Our maximum PCB size on high frequency materials is 400mm by 500mm, it can be a single board in the sheet and also can be different designs in this panel. Solder mask of green, black, blue and yellow etc is available in house. There’s immersion gold, HASL, immersion silver, immersion tin, pure gold and bare copper etc. for pads plating. TMM 4’s mechanical properties resist creep and cold flow. It is resistant to process chemicals, reducing damage during fabrication. All common PCB manufacturing processes can be used with TMM 4 materials, so the volume mass production is available for marketing.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com