What Are the Future Development Trends of Low-loss Materials?

Introduction

As the demand for high-frequency, high-speed electronics continues to surge, the role of advanced PCB materials like Megtron 6 (M6) and FR408HR has become increasingly critical. These low-loss laminates are essential for applications in 5G communications, automotive radar, data centers, and aerospace systems, where signal integrity and thermal reliability are paramount.

This article explores the future trends of low-loss materials, the technological advancements driving their adoption, and how leading PCB manufacturers are leveraging these materials to push the boundaries of performance. Additionally, we highlight our latest 6-layer Megtron 6 PCB, engineered for high-frequency and high-speed applications, as a prime example of next-generation PCB solutions.

The Growing Importance of Low-Loss Materials

Why Megtron 6 and FR408HR?

Traditional FR-4 materials, while cost-effective, struggle with dielectric losses (Df) and signal degradation at high frequencies. In contrast, Panasonic Megtron 6 and Isola FR408HR offer superior electrical properties:

Ultra-low dissipation factor (Df):

-

Megtron 6: 0.002 @ 1GHz (vs. ~0.020 for standard FR-4)

-

FR408HR: 0.010 @ 1GHz (optimized for high-speed digital)

-

Stable dielectric constant (Dk):

-

Megtron 6: 3.34 @ 13GHz (minimal variation with frequency)

-

FR408HR: 3.70 @ 10GHz (balanced for digital & RF)

Exceptional thermal performance:

High Tg (>185°C) and Td (410°C) for reliability in harsh environments

These properties make them ideal for 5G mmWave, automotive radar (77GHz), and 400G/800G optical modules, where signal loss and heat dissipation are critical challenges.

Market Trends Driving Adoption

1) 5G & mmWave Expansion

-

The rollout of 5G-Advanced and 6G will require even lower-loss materials to support higher frequencies (up to 300GHz).

-

Megtron 6’s low Df (0.0037 @ 13GHz) makes it a top choice for mmWave antennas and RF front-ends.

2) AI & Data Center Boom

-

AI servers demand ultra-high-speed interconnects (112Gbps+ SerDes).

-

Megtron 6’s low insertion loss is crucial for PCIe 6.0 and 800G optical modules.

3) Automotive Radar & ADAS

-

77/79GHz radar PCBs require materials with minimal signal distortion.

-

FR408HR offers a cost-effective alternative for mid-range ADAS applications.

4) Aerospace & Defense

-

Satellite communications and phased-array radars need materials with stable Dk/Df across extreme temperatures.

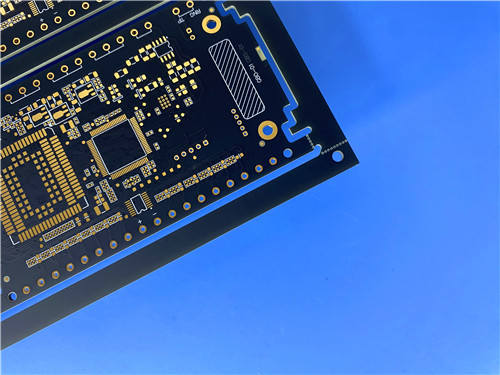

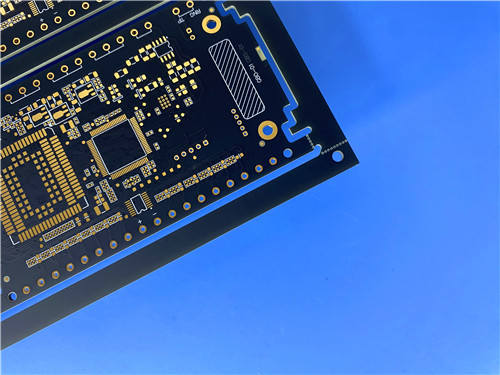

Introducing Our Latest Megtron 6 PCB: A Benchmark in High-Speed Design

To meet these evolving demands, we have developed a 6-layer Megtron 6 PCB material R-5775G (HVLP) PCB, optimized for high-frequency and high-speed digital applications.

Key Specifications:

Parameter Details

-

Base MaterialMegtron 6 (M6) R-5775G (HVLP)

-

Layer Count6-layer rigid PCB

-

Dimensions81.9 mm x 53.7 mm (±0.15mm)

-

Min Trace/Space4/5 mils

-

Min Hole Size0.3mm

-

Finished Thickness1.4mm

-

Cu Weight1oz outer, 0.5oz inner

-

Via Plating25μm

-

Surface FinishENEPIG (Immersion Gold)

-

Solder MaskMatte Black (Top/Bottom)

-

SilkscreenWhite

-

Via Treatment0.3mm vias filled with resin & capped

-

Testing100% electrical test before shipment

Advanced Stackup for Signal Integrity

Our 6-layer stackup PCB ensures optimal impedance control and low insertion loss:

Top Layer (35μm Cu)

Prepreg (R-5670G, 85.1μm)

Inner Layers (17μm Cu, Megtron 6 Core)

Prepreg (R-5670G, 99.4μm)

Bottom Layer (35μm Cu)

This design minimizes skew and crosstalk, critical for high-speed differential pairs (e.g., PCIe, DDR5).

Why Choose This PCB?

✔Ultra-Low Loss: Megtron 6’s Df of 0.002 ensures minimal signal degradation.

✔High Thermal Reliability: Tg >185°C, Td 410°C for harsh environments.

✔ENEPIG Finish: Superior surface conductivity for high-frequency RF & fine-pitch BGA components.

✔Resin-Filled Vias: Enhanced reliability for automotive & aerospace applications.

The Future of Low-Loss Materials: What’s Next?

1. Hybrid Material Solutions

-

Combining Megtron 6 with PTFE for mmWave (60GHz+) applications.

-

Embedded passive components to reduce signal path length.

2. Sustainable Low-Loss Materials

-

Halogen-free, RoHS-compliant formulations (already supported by Megtron 6).

-

Recyclable substrates for eco-friendly PCB manufacturing.

3. AI-Driven Material Optimization

-

Machine learning models to predict Dk/Df behavior under different conditions.

-

Automated impedance tuning for ultra-high-speed designs.

Conclusion: Leading the Next Wave of High-Speed PCBs

As 5G, AI, and autonomous driving push the limits of PCB performance, low-loss materials like Megtron 6 and FR408HR will remain at the forefront. Our new 6-layer Megtron 6 PCB exemplifies how advanced materials can deliver unmatched signal integrity, thermal stability, and reliability for next-gen applications.

For engineers and designers seeking high-frequency, low-loss solutions, our Megtron 6-based PCBs offer a proven path to success. Available worldwide with IPC-Class-2 quality assurance, we are ready to support your most demanding projects.

Contact us today to explore how our low-loss PCB solutions can power your next breakthrough.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com