Introduction:

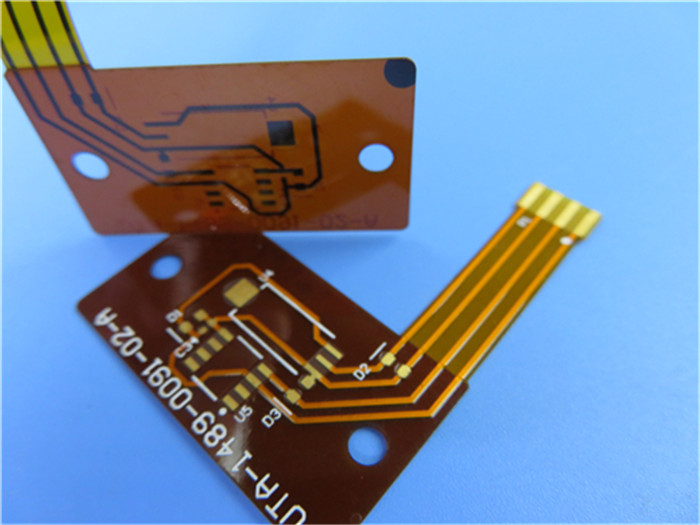

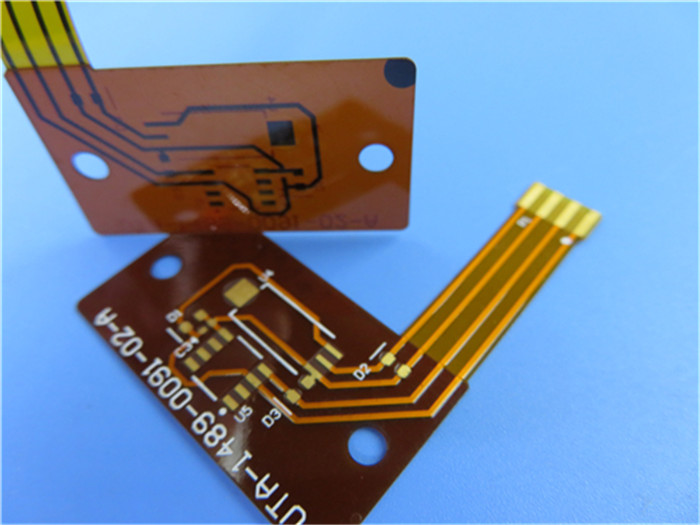

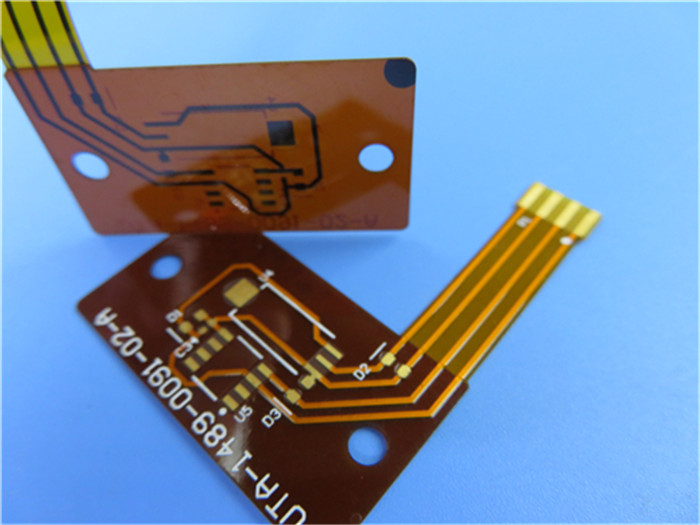

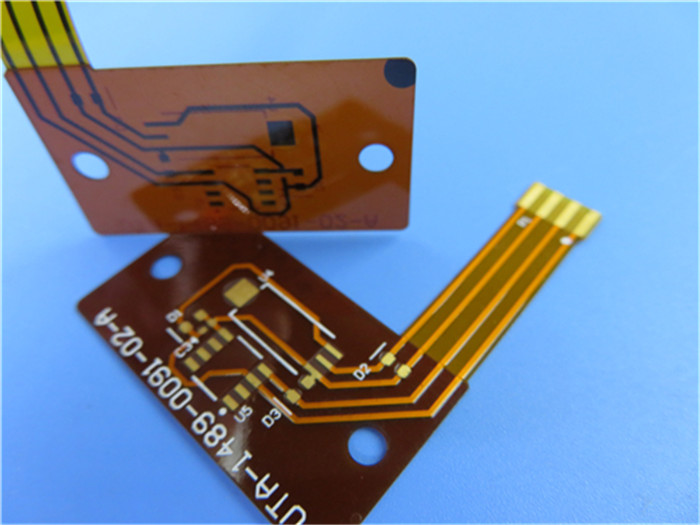

In the world of electronic manufacturing, adhesiveless polymide flexible PCBs have gained popularity due to their flexibility, electrical properties, and compatibility with RoHS directives. However, it is crucial to critically evaluate any product to understand its limitations and potential drawbacks. In this article, we delve into the properties of Adhesiveless Polyimide FLexible PCB 0.13 mm and shed light on their shortcomings, providing a balanced perspective on their use in various applications.

Adhesiveless Flexible PCB Properties:

Adhesiveless flexible polymide PCBs are constructed using single-sided adhesiveless flexible PCB copper clad laminate. They possess a dielectric constant (Dk) of 3.51 at 10 GHz/23°C, which determines their ability to transmit electrical signals. With a dissipation factor of 0.0059 at 10 GHz/23°C, Flexible PCB material offer low signal loss during transmission.

Adhesiveless Flexible PCB Benefits:

One of the advantages of adhesiveless flexible PCBs is their excellent soldering reliability, dimensional stability, and chemical resistance. Their flexibility allows them to be bent or twisted to fit into tight spaces, making them suitable for various applications. Moreover, being halogen-free and compliant with the EU RoHS directive, they ensure compliance with environmental regulations by avoiding the use of harmful substances.

Limitations and Criticisms:

1. Limited Complexity and Layer Count: Adhesiveless flexible PCBs are usually limited to single-layer construction due to the absence of an adhesive bonding layer. This restricts their use in applications that require complex circuitry and multiple layers, thereby limiting their versatility.

2. Reduced Mechanical Strength: Compared to rigid PCBs, adhesiveless flexible PCBs generally exhibit lower mechanical strength. Excessive bending or repeated flexing may cause stress concentration and lead to premature failure, impacting the overall reliability of the product.

3. Limited Temperature Range: While adhesiveless flexible PCBs are specified for operation in a temperature range of -40°C to +85°C, prolonged exposure to extreme temperatures at either end of this range can affect their performance and longevity.

4. Size and Weight Constraints: Adhesiveless polymide flexible 0.13mm PCBs are typically thinner and lighter than their rigid counterparts. While this property is advantageous in weight-sensitive applications, it also means that theFlexiblePCBsmay have limited mechanical rigidity and may not provide adequate support for heavier components or structures.

5. Design and Manufacturing Complexity: Due to their unique characteristics, adhesiveless flexible PCBs often require specialized design and manufacturing techniques. This can increase the complexity and cost of the overall production process.

Conclusion:

Adhesiveless flexible PCBs offer several benefits, including excellent soldering reliability, flexibility, and compliance with environmental regulations. However, it is essential to consider their limitations before incorporating them into certain applications. Their constraints concerning complexity, mechanical strength, temperature range, and design considerations should be carefully evaluated to ensure optimal performance and reliability.

While adhesiveless flexible material PCBs have found success in a range of applications such as computers, mobile phones, and automotive electronics, it is important to assess their suitability for specific projects based on their unique properties and constraints.

For technical inquiries or further information, please contact Jane at sales20@bichengpcb.com. Critical evaluation and consideration of the limitations of adhesiveless flexible PCBs will aid in making informed decisions and achieving the desired outcomes in electronic product development.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com