As 5G Technology develops, more and more devices request high-performance

high-frequency PCBs and

RF PCBs that need low signal losses and low electrical noise.

Rogers PCB materials are cost-effective and perfectly meets the required technological requirements.

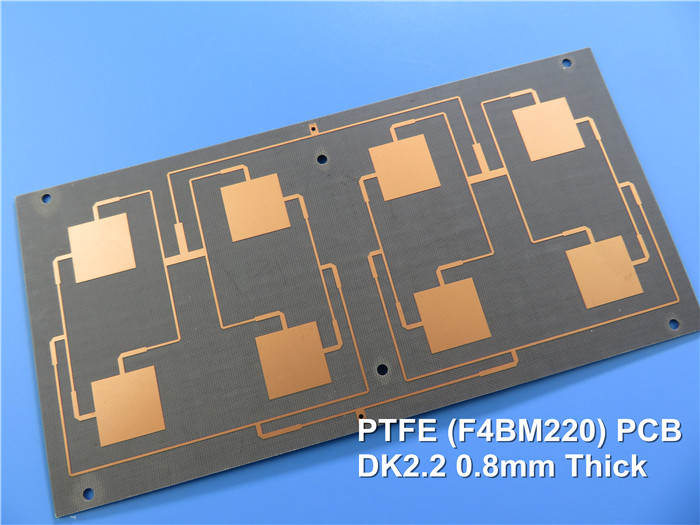

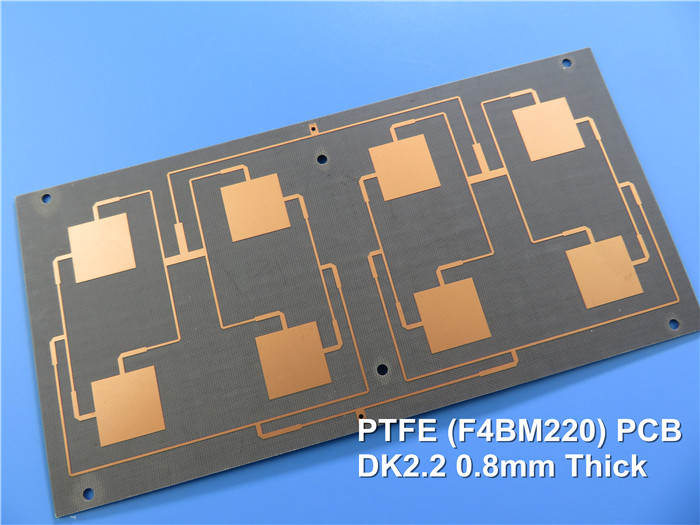

Rogers PCB is a type of high-frequency board that raw material is produced by Rogers company. It is different from the conventional PCB board—epoxy resin (FR4). It has no glass fiber in the middle and uses a ceramic base as the high-frequency material. Rogers has superior dielectric constant and temperature stability. Its dielectric constant thermal expansion coefficient is very consistent with copper foil, which can be used to improve the deficiencies of PTFE substrates. It is very suitable for high-speed electronic design, commercial microwave, and radio frequency applications. Its low water absorption is ideal for high-humidity applications, providing customers in the high-frequency board industry with the highest quality materials and related resources, which fundamentally enhance product quality.

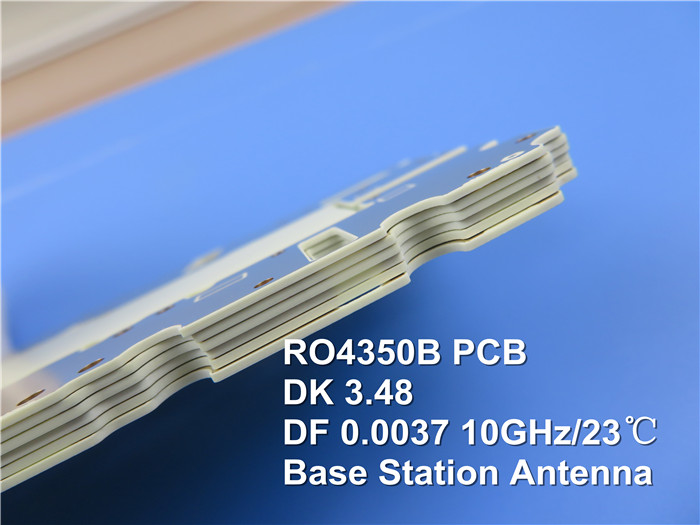

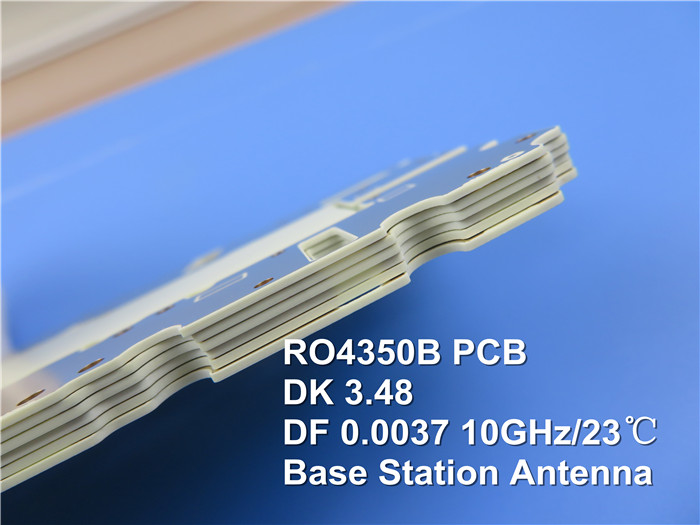

ROGERS 4003C and ROGERS 4350B have excellent low dielectric loss characteristics. As a result, they provide a more cost-effective and processable high-frequency material selection than PTFE. They are widely used in antennas of the cellular base station and power amplifiers, microwave point-to-point connection (P2P), automotive radars and sensors, radio frequency identification (RFID), direct broadcast satellite high-frequency head (LNB), and other fields. In addition, the thermal expansion coefficient of the X and Y-axis is similar to that of copper. The expansion coefficient of the Z-axis is much lower than FR4 (46ppm/ oC) and has a higher Tg value (>280oC), thus ensuring good thermal stability. The dimensional stability and high reliability of the entire product in PCB processing and assembly will bring more benefits to the design of multilayer circuits.

When the circuit’s operating frequency is above 500MHz, the range of materials that design engineers can choose is significantly reduced. Rogers RO4350B material allows RF engineers to conveniently design circuits, such as network matching and impedance control of transmission lines. Due to its low dielectric loss characteristics, in high-frequency applications, RO4350B material has more advantages than ordinary circuit raw materials. Its dielectric constant with temperature fluctuation is almost the lowest among similar materials. In a wide frequency range, its dielectric constant is also relatively stable at 3.48; the recommended design value is 3.66. LoPra copper foil can reduce insertion loss, which makes the material suitable for broadband applications.

Bicheng always has all the thickness and specifications of RO4003C, RO3003C, RO4350B, RO5880, RO5870, and RO4450F prepregs, which can meet your immediate response needs. We have rich experience in RFID data process engineering and a complete high-frequency material processing control system to ensure product design functions.

The distinction between Rogers Material and an FR-4 Material

-

Rogers material is more expensive compared to an FR-4 material

-

The quality of a Rogers PCB material proves higher than an FR-4 material

-

A Rogers material possesses a lower dissipation factor (DF) compared to an FR-4 material and thus suffers lesser signal losses.

-

Rogers material possesses a wider Dk (dielectric constant) range than an FR-4 material and thus has more impedance stability.

-

A Rogers’s material contains a higher Dk of 6.15 to 11 compared to an FR-4 material that possesses a Dk of 4.5

-

A Rogers’s material also contains a better temperature or thermal management due to its limited variation than FR-4 material.

-

A Rogers’s material also improves the impedance control in a better way compared to an FR-4 material.

As demonstrated, the application of Rogers PCB laminates is superior to that of standard FR-4 material and proves its usefulness in a printed circuit board. However, to get your PCB developed by this laminate and to the highest standards, you need to find a top company among the various Rogers PCB manufacturers out there.

What’s more,

Bicheng will provide top-rate quality PCBs based on your PCB needs. It has a demonstrated experience of over 15 years producing Rogers PCBs. Lastly, the dedicated customer support system exists to cater to your Rogers PCB price inquiries and other related aspects that can expedite your Rogers PCB order.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com