How to Choose Between RO4350B, PTFE, and Ceramic-Filled Substrates?

Introduction

High-frequency PCBs are critical in modern RF and microwave applications, including 5G communications, radar systems, and satellite technology. Selecting the right substrate material is essential to ensure signal integrity, thermal stability, and manufacturability. Three of the most commonly used high-frequency PCB materials are Rogers RO4350B, PTFE (Teflon), and ceramic-filled laminates.

In this guide, we’ll explore the properties, advantages, and trade-offs of each material and provide insights on how to choose the best option for your application. We’ll also showcase a real-world6-layer RF PCB example using RO4350B and RO4450F bondply to illustrate material selection in practice.

Key Considerations for High-Frequency PCB Materials

Before diving into material specifics, let’s outline the key factors that influence substrate selection:

-

-Dielectric Constant (Dk)–Affects signal propagation speed and impedance control.

-

-Dissipation Factor (Df)–Determines signal loss at high frequencies.

-

-Thermal Conductivity–Important for heat dissipation in power applications.

-

-Coefficient of Thermal Expansion (CTE)–Impacts reliability under thermal cycling.

-

-Manufacturability–Some materials require specialized processing.

-

-Cost- High-performance materials can be expensive.

Now, let’s compare the three leading high-frequency PCB materials.

1. RO4350B: The Cost-Effective High-Performance Option

Rogers 4350B is a woven glass-reinforced hydrocarbon/ceramic laminate that offers a balance between electrical performance and ease of fabrication.

Key Features of RO4350B

-

-Dielectric Constant (Dk): 3.48±0.05 @ 10 GHz

-

-Dissipation Factor (Df): 0.0037 @ 10 GHz (low loss)

-

-Thermal Conductivity: 0.69 W/m/°K (better than FR4)

-

-CTE: Low expansion (X/Y: 10-12 ppm/°C, Z: 32 ppm/°C)

-

-Tg (Glass Transition Temp): >280°C (excellent thermal stability)

-

-Moisture Absorption: 0.06% (minimal impact on performance)

Why Choose RO4350B?

✔Cost-Effective Alternative to PTFE–RO4350B performs close to PTFE but at a lower cost.

✔Compatible with Standard FR4 Processes–No special drilling or plating required.

✔Stable Dk Over Frequency & Temperature–Ideal for RF and microwave circuits.

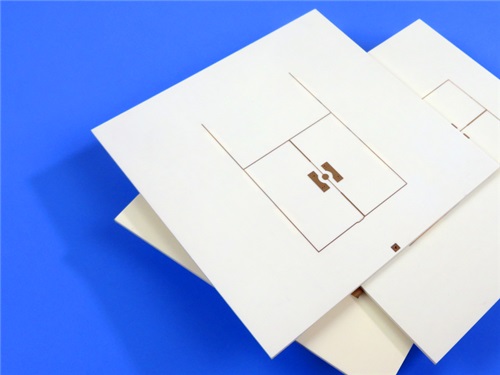

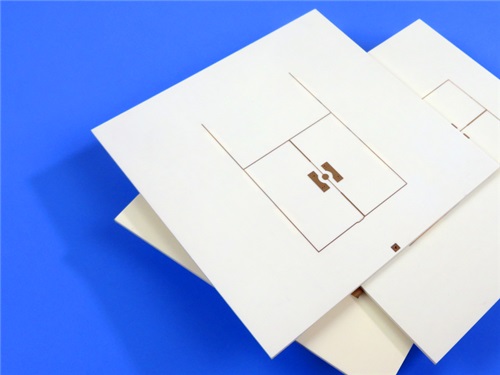

Example: 6-Layer RF PCB Using RO4350B

Here’s a real-world PCB we manufactured using RO4350B cores and RO4450F bondply:

Layer Count: 6

Dimensions: 98.5 mm×68 mm (±0.15mm)

Min Trace/Space: 4/6 mils

Min Hole Size: 0.3mm

Blind Vias: L1-L2, L3-L6, L5-L6

Board Thickness: 1.8mm

Surface Finish: Immersion Gold

Solder Mask: Green (top & bottom)

Quality Standard: IPC-Class-2

Stackup Structure:

Top Layer (35µm Cu)

RO4350B Core (0.254mm)

Inner Layer (35µm Cu)

RO4450F Bondply (4mil, 2x)

RO4350B Core (0.762mm)

Bottom Layer (35µm Cu)

This design is optimized for RF applications with controlled impedance and low insertion loss.

2. PTFE (Teflon): The Ultra-Low Loss Solution

PTFE (Polytetrafluoroethylene) is the gold standard forultra-high-frequency PCBs due to its extremely low loss.

Key Features of PTFE

-

Dk: 2.1–3.5 (varies with filler material)

-

Df: As low as 0.0009 (best for mmWave applications)

-

Thermal Stability: Excellent, but high CTE (~160 ppm/°C)

-

Challenges: Requires specialized drilling/plating processes.

When to Use PTFE?

✔Millimeter-Wave (mmWave) Circuits (24GHz+, 5G, radar)

✔Extremely Low-Loss Applications (satellite comms, aerospace)

✖Not Ideal for Cost-Sensitive Projects (higher fabrication costs)

3. Ceramic-Filled Materials: High Thermal & Mechanical Stability

Ceramic-filled substrates (e.g.,Rogers RO3000 series) offer enhanced thermal conductivity and mechanical strength.

Key Features of Ceramic-Filled Laminates

-

Dk: 3.0–10.2 (adjustable based on ceramic content)

-

Df: 0.001–0.003 (low loss, but not as good as PTFE)

-

Thermal Conductivity: Up to 4 W/m/°K (great for power amplifiers)

-

CTE: Matches copper (~17 ppm/°C), reducing warping risks.

Best Applications for Ceramic-Filled PCBs

✔High-Power RF Devices (base stations, power amplifiers)

✔Applications Needing Heat Dissipation (automotive radar, LED PCBs)

Material Selection Guide: RO4350B vs. PTFE vs. Ceramic

|

Parameter

|

RO4350B

|

PTFE

|

Ceramic-Filled

|

|

Dk (10 GHz)

|

3.48 ±0.05

|

2.1–3.5

|

3.0–10.2

|

|

Df (10 GHz)

|

0.0037

|

0.0009–0.002

|

0.001–0.003

|

|

Thermal Conductivity

|

0.69 W/m/°K

|

Low (~0.2)

|

Up to 4 W/m/°K

|

|

CTE (ppm/°C)

|

X/Y: 10-12, Z: 32

|

~160 (high)

|

~17 (matches Cu)

|

|

Cost

|

Medium

|

High

|

Medium-High

|

|

Manufacturing Ease

|

Easy (FR4-like)

|

Difficult (special processes)

|

Moderate

|

Which One Should You Choose?

-

For most RF applications (up to 20GHz), RO4350B Frequency PCB is the best balance of cost and performance.

-

For mmWave (24GHz+), PTFE is ideal but expensive.

-

For high-power/high-thermal applications, ceramic-filled laminates are superior.

Conclusion

Selecting the right high-frequency PCB material depends on your application’s frequency range, thermal requirements, and budget.

RO4350B PCB is the best all-around choice for most RF designs, offering low loss, stable Dk, and easy fabrication.

PTFE is unmatched for ultra-low-loss mmWave circuits but comes at a higher cost.

Ceramic-filled materials excel in high-power and high-thermal scenarios.

Our 6-layer RF PCB example demonstrates howRogers4350B and RO4450F bondply can be used effectively in real-world designs. If you need high-frequency PCBs with optimized material selection, we provide global manufacturing with IPC-Class-2 quality standards.

Need a custom RF PCB solution? Contact us today for expert guidance!

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com