Rogers PCBs: History, Features, and Benefits

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost all electronic devices, from smartphones to medical equipment. Rogers PCBs, in particular, are known for their high performance and reliability.

Rogers Corporation, a US-based company, developed Rogers PCBs in the 1960s. They were initially used in military and aerospace applications due to their high reliability and performance in extreme environments. Since then, Rogers PCBs have found use in a wide range of industries, including telecommunications, automotive, and medical.

Features of Rogers PCBs:

High Frequency Performance: Rogers PCBs have a low dielectric loss and a stable dielectric constant, making them ideal for high-frequency applications.

High Thermal Stability: Rogers PCBs have a low coefficient of thermal expansion (CTE) and can withstand high temperatures without degrading, making them ideal for use in extreme environments.

Low Water Absorption: Rogers PCBs have a low water absorption rate, which helps to prevent delamination and improve the overall reliability of the PCB.

Benefits of Rogers PCBs:

Improved Signal Integrity: Rogers materials have a low dielectric constant and a low dissipation factor, which helps to reduce signal loss and improve signal integrity, making them ideal for high-speed digital and RF applications.

Reduced Cross-Talk: Rogers PCBs have a low dielectric constant and a low dissipation factor, which helps to reduce cross-talk between adjacent traces.

Improved Thermal Management: Rogers PCBs have a low CTE and high thermal conductivity, which helps to improve thermal management and prevent thermal stress on components.

Reduced Cross-Talk: Rogers materials have a low dielectric constant and a low dissipation factor, which helps to reduce cross-talk between adjacent traces.

There are several types of Rogers materials used in the construction of Rogers PCBs, including:

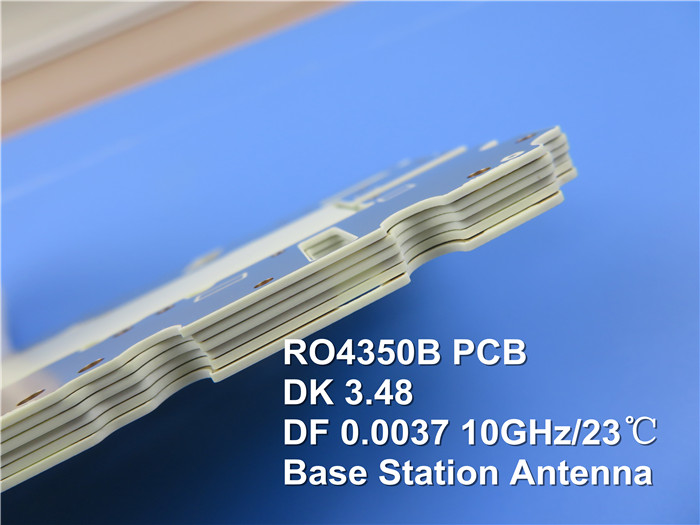

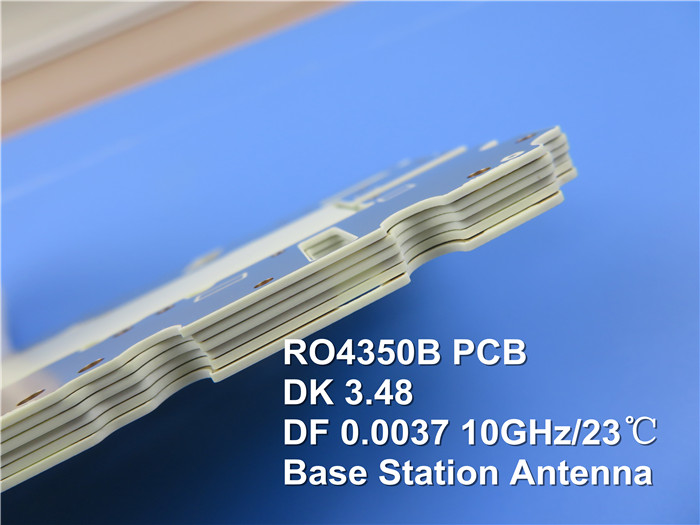

Rogers 4350 PCB: Rogers 4350 is a ceramic-filled hydrocarbon material that is used in high-frequency applications. It has a low dielectric constant (3.48) and a low dissipation factor (0.0037), which makes it ideal for high-speed digital and RF applications.

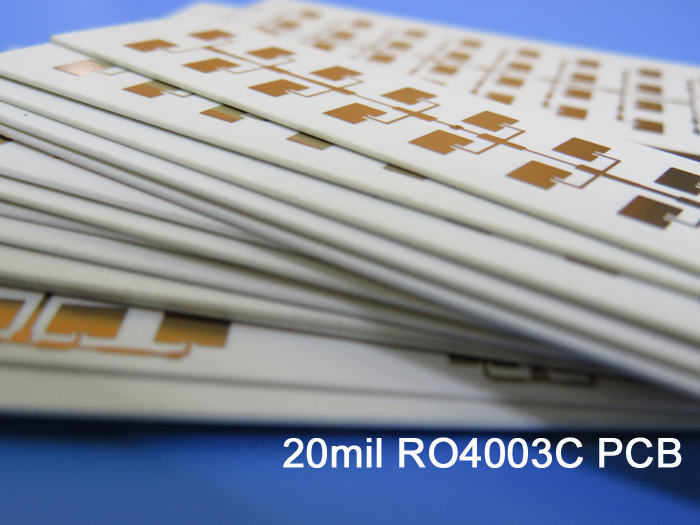

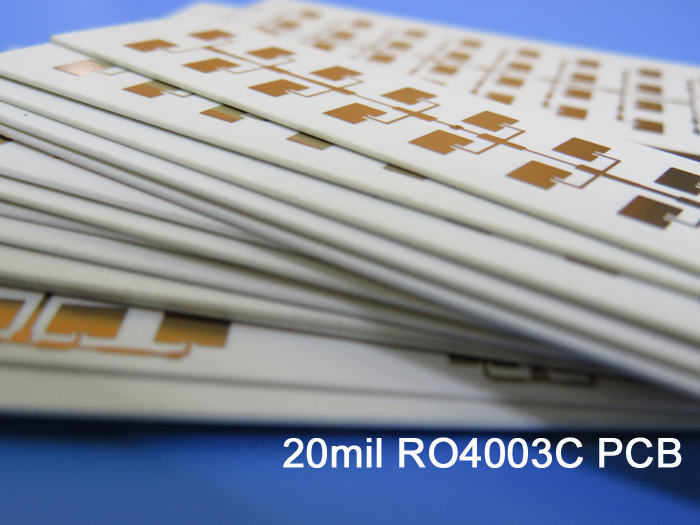

Rogers 4003 PCB: Rogers 4003 is a glass-reinforced hydrocarbon material that is used in high-frequency applications. It has a low dielectric constant (3.38) and a low dissipation factor (0.0027), which makes it ideal for high-speed digital and RF applications.

Rogers 5880 PCB: Rogers 5880 is a microfiber reinforced PTFE material that is used in high-frequency applications. It has a low dielectric constant (2.20) and a low dissipation factor (0.0009), which makes it ideal for high-speed digital and RF applications.

Rogers 3003 PCB: Rogers 3003 is a ceramic-filled PTFE material that is used in high-frequency applications. It has a low dielectric constant (3.00) and a low dissipation factor (0.0013), which makes it ideal for high-speed digital and RF applications.

Rogers 3010 PCB: Rogers 3010 is a ceramic-filled PTFE composite that is used in high-frequency applications. It has a high dielectric constant (10.2) and a low dissipation factor (0.004), which makes it ideal for applications that require high thermal stability and low signal loss.

RT/duroid 5870 PCB: This is a high-frequency laminate material that is made up of woven fiberglass and PTFE resin. It has a low dielectric constant of 2.33 and is commonly used in high-frequency applications.

RO3006 PCB: This material is a ceramic-filled PTFE laminate that is used in high-frequency applications. It has a high dielectric constant of 6.15 and is known for its low loss tangent and excellent thermal stability.

RO3035 PCB: This is another ceramic-filled PTFE substrate that is designed for high-frequency applications. It has a low dielectric constant of 3.55 and a low loss tangent, making it ideal for high-speed digital and RF applications.

RT/duroid 6002 PCB: This is a ceramic-filled PTFE laminate that is designed for high-frequency and high-power applications. It has a low dielectric constant of 2.94 and is known for its high thermal conductivity and excellent thermal stability.

RT/duroid 6006 PCB: This is a ceramic-filled PTFE laminate that is used in high-frequency and high-power applications. It has a low dielectric constant of 6.15 and is known for its low loss tangent and excellent thermal stability.

RT/duroid 6010: This material is a ceramic-filled PTFE laminate that is designed for high-frequency and high-power applications. It has a high dielectric constant of 10.2 and is known for its high thermal stability and low loss tangent.

RT/duroid 6035HTC PCB: This is a ceramic-filled PTFE laminate that is designed for high-frequency and high-temperature applications. It has a low dielectric constant of 3.5 and is known for its high thermal conductivity and excellent thermal stability at high temperatures.

RO4730 PCB: This is a high-performance hydrocarbon ceramic woven glass composite that is designed for high-frequency applications. It has a low dielectric constant of 3.0 and is known for its low loss tangent and excellent thermal stability.

RO4835 PCB: This material is a ceramic-filled hydrocarbon laminate that is used in high-frequency applications. It has a low dielectric constant of 3.48 and is known for its low loss tangent and excellent thermal stability.

RO4360G2 PCB: This is a high-performance hydrocarbon ceramic laminate that is designed for high-frequency and high-power applications. It has a low dielectric constant of 6.15 and is known for its low loss tangent and excellent thermal stability.

Each of these Rogers materials has specific properties that make them suitable for different applications. When selecting a Rogers PCB, it is important to choose a material that matches the requirements of your specific application in terms of frequency, power, thermal stability, and other factors.

Bichengpcb's DFM Capability:

Bichengpcb is a China-based PCB supplier that specializes in Rogers PCBs. They have extensive experience in manufacturing high-performance PCBs.

DFM is the process of designing a PCB to ensure that it can be manufactured efficiently and reliably. Bichengpcb's DFM services include:

PCB Layout Review: Bichengpcb's engineers review the PCB layout to ensure that it meets the manufacturer's design rules and can be manufactured reliably.

Design for Assembly (DFA) Review: Bichengpcb's engineers review the PCB design to ensure that it can be assembled efficiently and reliably.

Design for Test (DFT) Review: Bichengpcb's engineers review the PCB design to ensure that it can be tested efficiently and reliably.

Material Selection: Bichengpcb's engineers help customers select the most appropriate materials for their PCBs based on their specific requirements.

Cost Optimization: Bichengpcb's engineers work with customers to optimize the design of their PCBs to reduce manufacturing costs without compromising performance or reliability.

Conclusion:

Rogers PCBs are a high-performance alternative to traditional PCBs, offering improved signal integrity, reduced cross-talk, and improved thermal management. The use of specialized Rogers materials in their construction ensures that they can perform reliably in high-frequency and high-power applications. When selecting a Rogers PCB, it is important to consider the specific properties of the Rogers material being used and how they will impact the performance of the PCB in your application.

Bichengpcb's DFM capability ensures that customers can design and manufacture Rogers PCBs efficiently and reliably.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com