A Comprehensive Guide to RF-60TC: Is It the Superior High-Frequency PCB Substrate for Your Project?

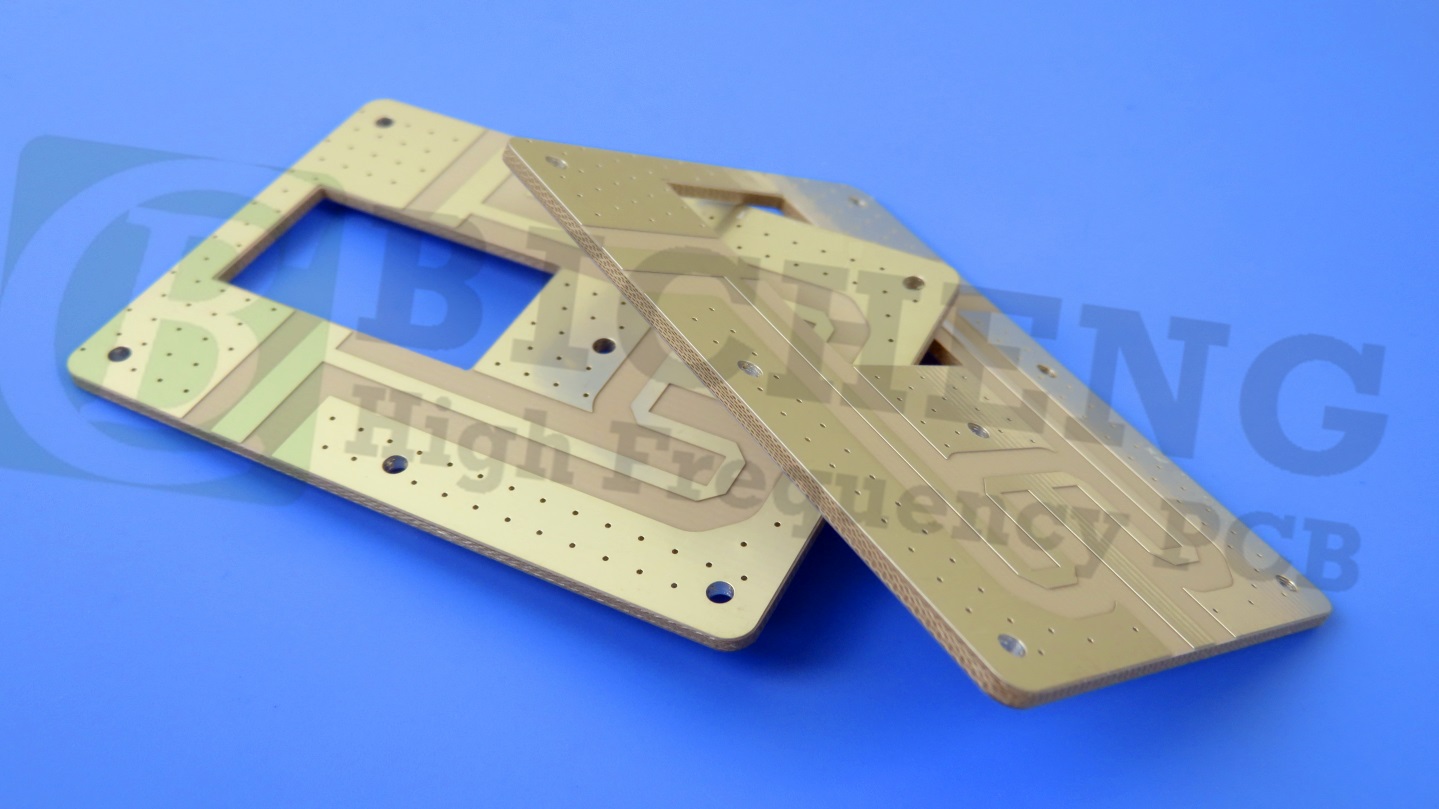

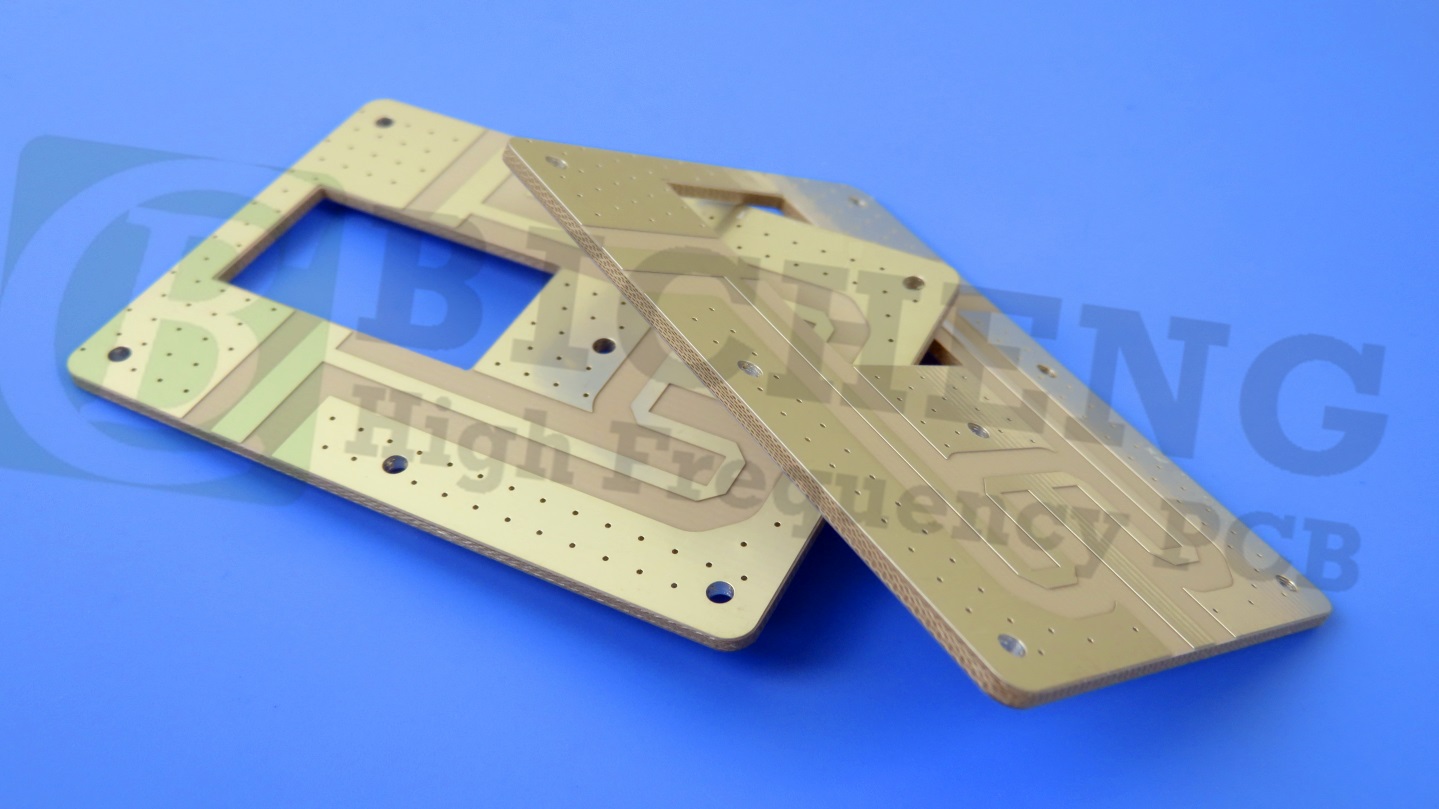

In the rapidly advancing world of wireless technology, the demand for high-performance, reliable printed circuit boards (PCBs) is greater than ever. For engineers and designers working on cutting-edge RF and microwave systems, selecting the right substrate material is a critical decision that directly impacts product performance, efficiency, and longevity. Enter the RF-60TC High Frequency PCB, a premier PTFE-based, ceramic-reinforced composite material engineered to excel in the most demanding high-power applications. This blog delves into the superior properties, extensive manufacturing capabilities, and diverse applications of this exceptional material.

Unveiling the RF-60TC: A Material Engineered for Excellence

The Taconic RF-60TC is not just another PCB substrate; it represents a significant leap forward in material science. Crafted from a polytetrafluoroethylene (PTFE) base infused with ceramic and woven fiberglass, it is specifically formulated to address the unique challenges of high-frequency circuits. A key differentiator is its ability to maintain operational stability at elevated power levels while generating lower operating temperatures. This characteristic is paramount for enhancing power gains and boosting overall system efficiency, particularly in the increasingly prevalent miniaturized antenna systems operating within a controlled dielectric constant (Dk) of 6.15. These advantages are primarily derived from the material's superior dielectric heat dissipation properties and its exceptionally low signal loss, ensuring pristine performance.

A Deep Dive into the Defining Features of RF-60TC

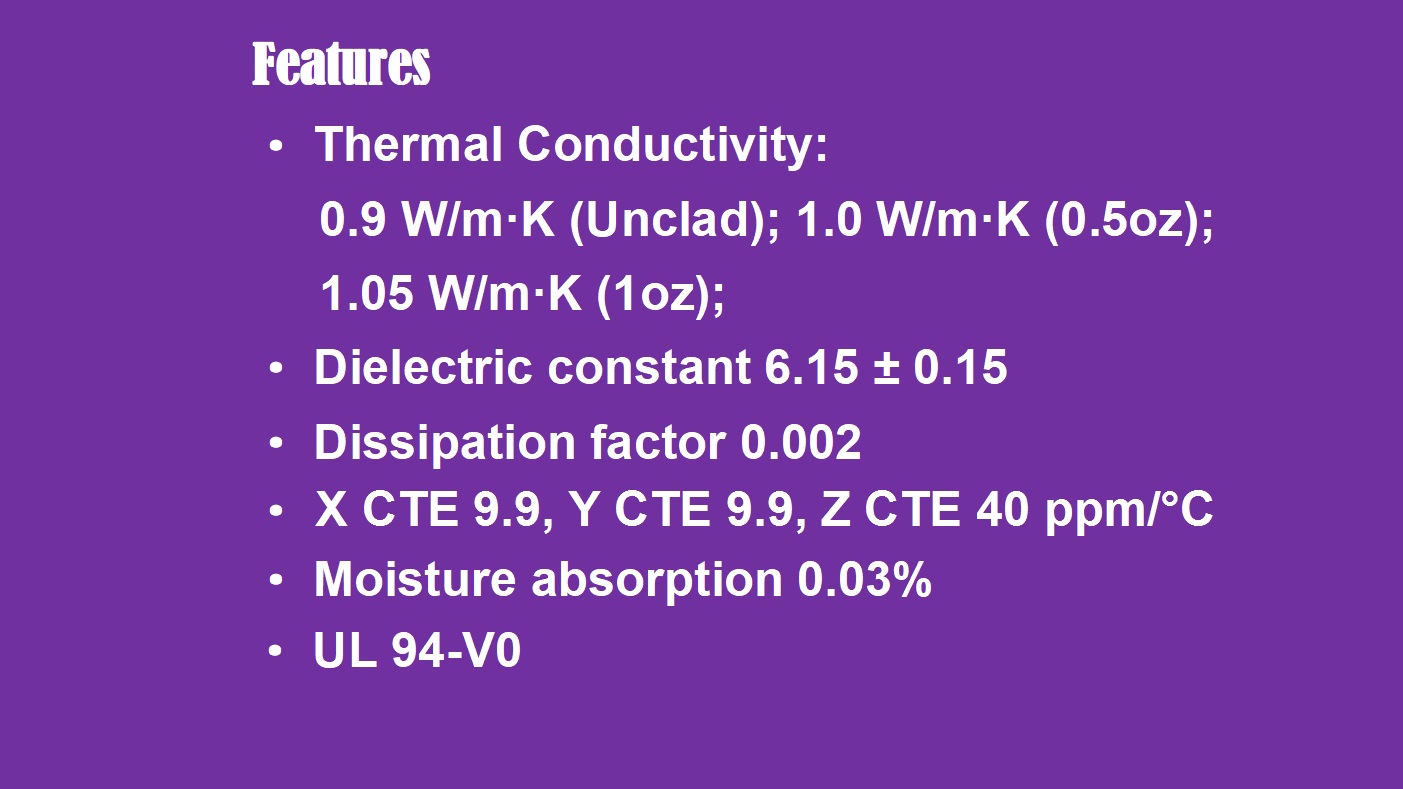

The exceptionalism of the RF-60TC material is underscored by its robust set of technical attributes:

1) Superior Thermal Conductivity: A standout feature is its impressive thermal management capability. The substrate offers thermal conductivity values of 0.9 W/m·K for unclad laminates, which increases to 1.00 W/m·K for 0.5oz copper cladding and 1.05 W/m·K for 1oz cladding. This efficient heat dissipation reduces thermal stress on active components, thereby extending their operational lifespan and guaranteeing long-term reliability for your designs.

2) Stable Dielectric Constant: With a consistent dielectric constant (Dk) of 6.15±0.15 measured at 10 GHz, the RF-60TC provides exceptional electrical predictability. This stability is crucial for impedance control and is a fundamental enabler of device miniaturization, allowing designers to optimize board space without sacrificing electrical performance.

3) Minimal Dissipation Factor: The material exhibits an extremely low dissipation factor (Df) of just 0.002 at 10 GHz (as per IPC-650 2.5.5.5.1). This low loss tangent translates to highly efficient signal transmission, minimizing energy loss and preserving signal strength in sensitive RF applications.

4) Enhanced Dimensional Stability: The RF-60TC features a low coefficient of thermal expansion (CTE), with values of 9.9 ppm/°C in the X and Y axes and 40 ppm/°C in the Z-axis. This enhanced dimensional stability is vital for constructing complex, high-layer-count multilayer PCBs, as it ensures improved reliability of plated through holes (PTHs) across a wide temperature range.

5) Low Moisture Absorption: In harsh environmental conditions, moisture uptake can compromise a PCB's integrity. The RF-60TC boasts a remarkably low moisture absorption rate of 0.03% (IPC-650 2.6.2.1), ensuring consistent performance and unwavering environmental stability.

6) High Flammability Rating: Safety is never compromised. The material meets the stringent UL 94 V-0 flammability standard, confirming its self-extinguishing properties and high resistance to ignition.

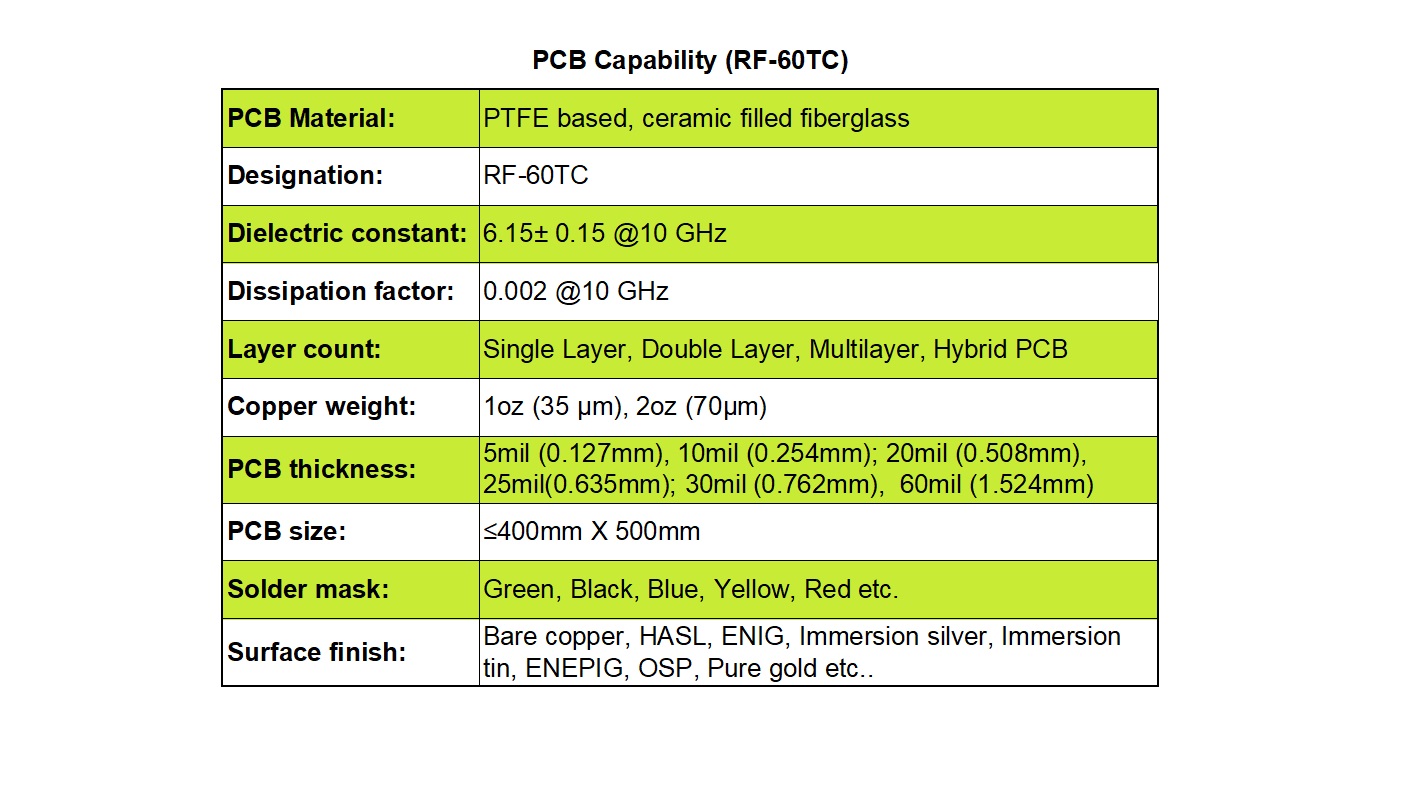

Our Advanced PCB Manufacturing Capabilities with RF-60TC

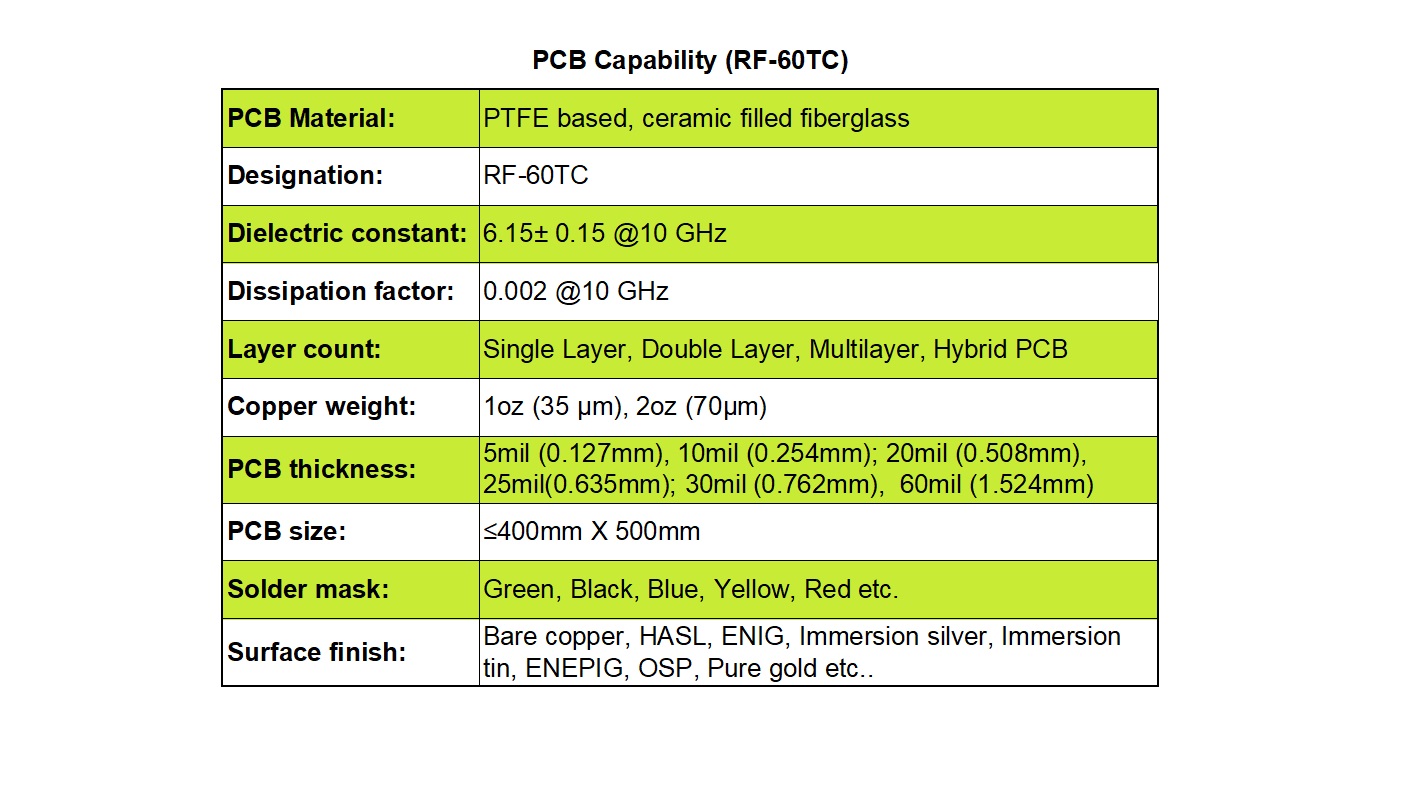

Leveraging this advanced material requires a manufacturing partner with precise technical expertise. We offer comprehensive fabrication services tailored to fully exploit the potential of RF-60TC Taconic High Frequency PCB:

Layer Count Versatility: We expertly manufacture everything from simple Single and Double Layer boards to sophisticated Multilayer and Hybrid multilayer constructions, combining different materials for optimal performance.

Flexible Copper Weight: To meet specific current-carrying and conductivity needs, we provide standard options of 1oz (35 µm) and 2oz (70µm) copper cladding.

Precision Thickness Control: We offer a wide spectrum of substrate thicknesses, including 5mil (0.127mm), 10mil (0.254mm), 20mil (0.508mm), 25mil (0.635mm), 30mil (0.762mm), and 60mil (1.524mm), granting unparalleled design flexibility.

Large Format PCBs: Our production facilities can handle substantial board sizes, accommodating panels up to 400mm x 500mm.

Custom Solder Mask: Aesthetic and functional choices are available with solder mask colors including Green, Black, Blue, Yellow, Red, and others.

Diverse Surface Finishes: To ensure solderability, durability, and performance, we provide a full suite of surface finishes: Bare copper, HASL, ENIG, Immersion Silver, Immersion Tin, ENEPIG, OSP, and Pure Gold.

Key Applications Driving Innovation

The unique property set of RF-60TC Taconic RF PCB makes them the substrate of choice for a broad spectrum of high-performance applications, including:

-

High-Power Amplifiers

-

Miniaturized Antennas for GPS, Patch, and RFID Reader Systems

-

Precision Filters, Couplers, and Power Dividers

-

Satellite Communication Technologies

Conclusion

The RF-60TC Taconic PCB material stands as a testament to innovation, offering an unparalleled combination of thermal management, electrical performance, and mechanical reliability. By choosing this advanced substrate and partnering with a capable manufacturer, you empower your designs to achieve new heights of efficiency and power in the competitive realm of RF and microwave electronics.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com