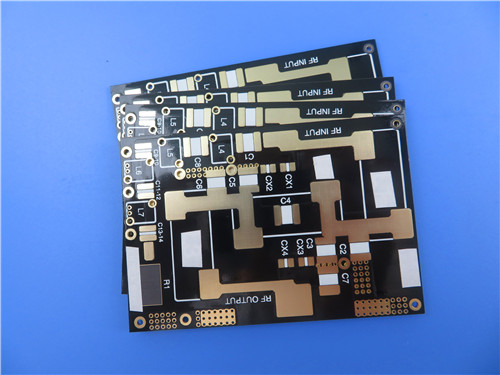

Can Wangling F4BTMS430 PCBs Replace Similar Foreign Materials in Demanding Applications?

The Wangling F4BTMS430 material and the PCBs built on it are specifically engineered to compete with and substitute for established foreign PTFE-ceramic laminates (such as those from Rogers, Taconic, or Arlon) in many critical scenarios. Here’s a detailed analysis of why and where it succeeds.

1. Direct Performance Parity in Key Metrics

The F4BTMS430 substrate formulation targets the core requirements of RF and microwave designs:

1)Low and Stable Dielectric Constant (Dk=4.3): Matches the Dk of popular foreign alternatives like Rogers RO4350B (Dk=3.66) or RO4003C (Dk=3.55), providing designers with a comparable, stable reference for impedance control. Its low Thermal Coefficient of Dk (-60 ppm/°C) ensures this stability is maintained across operational temperature ranges, a must for aerospace and outdoor equipment.

2)Ultra-Low Loss Tangent (Df=0.0019 @ 10GHz): This is a standout feature. Its dissipation factor is competitive with leading mid-range high-frequency materials, directly translating to lower signal attenuation and improved efficiency in power-sensitive applications like feed networks and phased array antennas.

3)Excellent Thermal and Mechanical Stability: With a low CTE (13/12 ppm/°C in X/Y), high thermal conductivity (0.63 W/mK), and UL-94V0 rating, it meets the mechanical reliability and thermal management demands of environments subject to vibration and temperature cycling.

2. Technological Advancements Addressing Traditional Weaknesses

The F4BTMS430 PCB material’s design philosophy directly tackles common limitations:

1)Reduced Glass Fiber Effect: By using minimal ultra-fine glass fiber, it mitigates the localized variations in dielectric constant that can cause signal integrity issues (like "weave effect") in standard glass-reinforced laminates, offering more predictable performance.

2)Optimized for High-Frequency Propagation: The homogeneous blend of nano-ceramics in PTFE minimizes anisotropy and dielectric loss, making it suitable for applications into the Ka-band (20GHz+), as evidenced by its specified performance at 20GHz.

3. Suitability for Target Demanding Applications

The specifications align perfectly with the needs of:

Aerospace & Defense: Its reliability, stable electrical properties, and low moisture absorption meet the stringent requirements for onboard electronics, cabin systems, and military radar.

Phased Array Antennas & SATCOM: These systems require consistent phase response across the array. The material's low loss and stable Dk vs. temperature are critical here, allowing it to replace foreign substrates in many elements of the feed and radiating system.

Commercial RF Infrastructure: For base station antennas, RF filters, and power amplifiers where performance consistency is key but cost sensitivity is higher than in pure military projects, F4BTMS430 offers an excellent balance.

Areas of Consideration and Potential Limitations

A complete replacement strategy requires honest assessment:

IPC Class 2 vs. Class 3: This specific PCB is built to IPC-Class-2 standards, which is suitable for most commercial aerospace and industrial applications. For the most critical, life-saving military/aerospace electronics where IPC-Class-3 (highest reliability) is mandated, verification and qualification at that class would be necessary.

Designer Familiarity & Modeling: Foreign materials have long-established design libraries, simulation models (e.g., in ANSYS HFSS or Keysight ADS), and a vast history of application notes. Switching requires designers to integrate the F4BTMS430's precise material parameters into their models and validate them, which involves some upfront engineering effort.

Extreme-End Performance: For the absolute highest-frequency applications (e.g., above 40GHz) or those requiring an extremely specific Dk not offered by this series, niche foreign materials might still hold an edge. However, for the vast majority of applications up through Ku/Ku-band, it is fully capable.

The Compelling Advantages of Choosing F4BTMS430

Beyond technical specs, the replacement offers strategic benefits:

1)Supply Chain Security & Flexibility: Reducing dependence on a single geographic or geopolitical source for critical materials is a major advantage for many global OEMs.

2)Cost-Effectiveness: Typically, domestically or regionally produced advanced materials like F4BTMS430 can offer significant cost savings without sacrificing performance, improving project ROI.

3)Direct Support & Collaboration: Working with a supplier like Wangling can provide more responsive technical support, shorter lead times, and opportunities for customization.

Conclusion

The Wangling F4BTMS430 PCB is not merely an alternative; it is a designed-for-replacement substrate for common foreign high-frequency laminates in a broad spectrum of demanding applications. Its performance metrics are directly competitive, and its material science addresses known industry challenges.

Recommendation: For new designs in aerospace, radar, satellite communication, and high-end RF infrastructure, F4BTMS430 high frequency PCB should be seriously evaluated as the primary material choice. For existing designs using similar foreign materials, a well-managed qualification and testing process can validate a successful switch, unlocking benefits in cost, supply chain robustness, and performance.

The era where only foreign brands could be trusted for mission-critical RF boards is ending. F4BTMS430 represents a proven, high-performance, and viable domestic/regional solution.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com