RO4000 series high frequency circuit board materials have high frequency performance and low production cost of circuit boards. It has low loss and similar processing technology to ordinary epoxy resin/glass woven cloth (FR4), so it has a strong price competitiveness.

When the circuit operating frequency is above 50OMHz, the range of materials that design engineers can choose is greatly reduced. RO4000 series materials allow RF engineers to conveniently design circuits, such as network matching and impedance control of transmission lines. Due to its low dielectric loss characteristics, in high frequency applications, RO4000 series materials have more advantages than ordinary circuit materials. Its dielectric constant with temperature fluctuation is almost the lowest among similar materials, and its dielectric constant is also quite stable in a wide frequency range. LoProR copper foil can reduce insertion loss. This makes the material suitable for broadband applications.

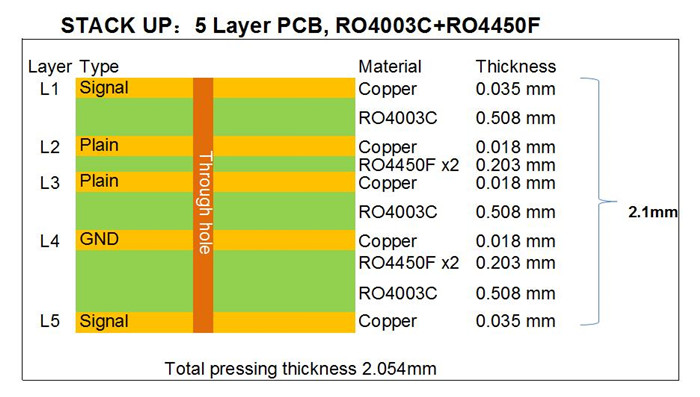

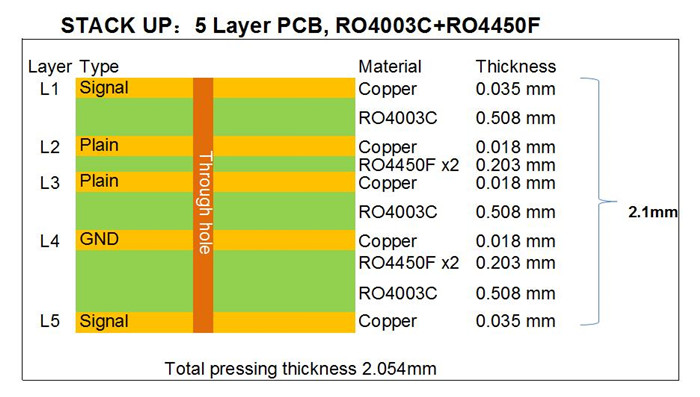

The coefficient of thermal expansion (CTE) of RO4000 series materials also brings many benefits to circuit designers. Since the coefficient is similar to that of copper, it can provide excellent dimensional stability. This is particularly important for multilayer circuit design. Even in severe thermal shock applications, the low Z-axis CTE expansion coefficient of RO4000 series materials ensures the quality of the through holes in the board. Because its Tg value is greater than 280C (536F), it guarantees good dimensional stability during the entire plate processing process.

The processing technology and process of RO4000 series materials are basically similar to those of ordinary FR4 sheets. Unlike PIFE materials, RO4000 series materials do not require through-hole pretreatment processes such as sodium etching. At the same time, it is a rigid, thermosetting material that can be processed using automated process systems and copper surface pretreatment grinding equipment.

RO4003CTM currently uses 1080 and 1674 glass fiber fabrics, and its electrical performance indicators are fully in line with the nominal values. If the design requires UL 94V-O flame retardant requirements and meets RoHS compatibility standards, RO4350BTM substrate is recommended.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com