How Does the 30mil Dk 3.3 RO4533 Optimize Performance in RF PCB Designs?

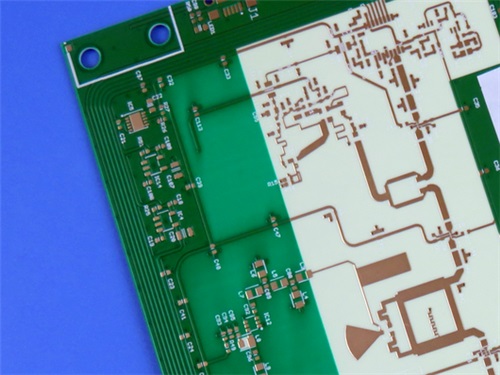

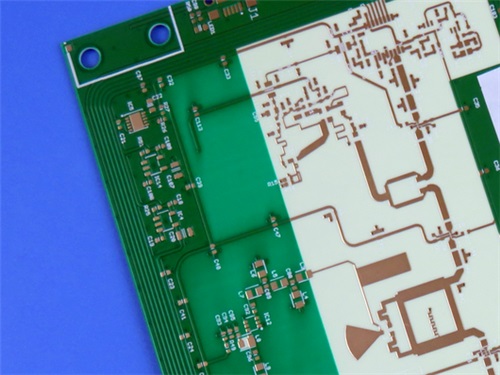

In the precise engineering realm of radio frequency (RF) and microwave circuit design, every material parameter serves a specific function. Rogers RO4533 laminate achieves an optimal balance for many antenna and RF applications through two defining characteristics: a 30mil (0.762mm) Rogers substrate thickness and a stable Dielectric Constant (Dk) of 3.3. Together, these parameters form the foundation for predictable, high-performance, and manufacturable circuit boards. This article explains how each factor independently and synergistically optimizes RF PCB performance.

The Foundation: Stable Dk 3.3 for Predictable Electrical Behavior

The Dielectric Constant (Dk orεᵣ) is a measure of how much a material concentrates electric flux. In RF design, the value is important, but its stability over frequency, temperature, and lot-to-lot manufacturing is paramount.

1. Precision Impedance Control and Signal Integrity

Transmission lines (microstrip, stripline) require precise characteristic impedance (typically 50Ωor 75Ω). The impedance calculation depends directly on the Dk of the substrate. RO4533's consistent Dk of 3.3 at 10 GHz allows engineers to:

Design with Confidence: Simulation models using this Dk value accurately predict real-world performance, reducing design iterations.

Achieve Manufacturing Consistency: PCBs from different production runs maintain identical electrical characteristics, ensuring every unit performs as specified.

Maintain Signal Integrity: A stable Dk prevents impedance mismatches that cause signal reflections, minimizing insertion loss and maximizing power transfer.

2. Optimized Antenna Resonance and Size

For patch antennas—a key application for RO4533—the resonant length of the radiating element is inversely proportional to the square root of the Dk. A Dk of 3.3 offers a strategic balance:

It allows for a physically smaller antenna compared to using a lower-Dk material (e.g., Dk 2.2), saving valuable board space.

It avoids the excessive electrical "shrinkage" and manufacturing sensitivity associated with very high-Dk materials, preserving bandwidth and radiation efficiency.

3. Stable Phase Response for Complex Systems

In phased-array antennas and sensitive filters, the electrical length and phase response are critical. Rogers 4533's low loss (Df 0.0025) and stable Dk ensure that the phase velocity of signals is predictable and consistent, enabling accurate beamforming and stable filter cutoffs across the operating band.

The Structural Lever: 30mil Thickness for Performance Tuning

Substrate thickness is a powerful degree of freedom for the RF designer, directly influencing bandwidth, efficiency, isolation, and thermal performance.

1. Enhanced Bandwidth for Antenna Applications

For patch antennas, bandwidth is directly proportional to substrate thickness. A 30mil (0.76mm) substrate provides significantly wider operational bandwidth than a thinner alternative (e.g., 20mil). This is crucial for modern wireless standards (4G/LTE, 5G) that require antennas to cover broad frequency ranges. The 30mil thickness offers an optimal trade-off, delivering substantial bandwidth without the mechanical bulk and potential higher-order mode excitation of excessively thick substrates.

2. Practical Impedance Realization

For a standard 50-ohm microstrip line on a Dk 3.3 material, a 30mil thickness results in a trace width that is ideal for manufacturing and performance.

The calculated width (~65-70 mils for 1oz copper) is neither excessively narrow (which increases loss and etching difficulty) nor overly wide (which consumes space).

This practical geometry supports fine-feature capabilities (down to 4/5 mil trace/space) for complex RF circuitry while maintaining robust, low-loss transmission lines.

3. Improved Circuit Isolation and Reduced Parasitics

A thicker dielectric increases separation between the signal layer and ground plane, which:

Reduces parasitic capacitance between traces and the ground plane.

Improves isolation between adjacent circuit elements, minimizing unwanted coupling and crosstalk.

For two-layer designs, it establishes a more well-defined ground reference, improving antenna pattern predictability and front-end circuit stability.

4. Mechanical and Thermal Robustness

The 0.762mm core provides a sturdy mechanical base, improving board rigidity and handling reliability. Combined with RO4533's relatively good thermal conductivity (0.6 W/m/K), this thickness aids in spreading heat from active components like power amplifiers, contributing to better thermal management and long-term reliability.

The Powerful Synergy: 30mil and Dk 3.3 Working in Concert

The true optimization emerges from the interaction of these two properties.

Predictable Effective Dk: In a microstrip line, the signal experiences an "effective Dk" between 1 (air) and the Dk 3.3 Rogers substrate. The 30mil thickness, relative to the practical trace width, results in an effective Dk that ensures strong field confinement within the substrate. This maximizes efficiency, minimizes radiative losses, and makes performance highly predictable through simulation.

Inherent Design for Manufacturing (DfM): This combination naturally leads to geometries compatible with high-yield PCB fabrication. It avoids the extreme aspect ratio drilling challenges of very thick boards and the delicate trace structures of very thin boards, supporting reliable plating (like 20μm via plating) and robust assembly.

Stable Performance Under Stress: RO4533’s high Tg (>280°C) and matched CTE to copper ensure that the critical 30mil thickness and the Dk value remain stable across temperature fluctuations during soldering and operation. This preserves the carefully designed electrical relationships in the field.

Conclusion: An Engineered Solution for High-Frequency Success

The specification of 30mil RO4533 PCB with a Dk of 3.3 represents a deeply optimized solution for a wide range of RF applications. It is not a default but a conscious choice that delivers:

Electrical Predictability through material stability.

Enhanced Performance through optimized bandwidth and low-loss characteristics.

Manufacturing Resilience through practical geometries and robust material properties.

For designers of cellular infrastructure, point-to-point radios, and aerospace communication systems, this material configuration provides a reliable, high-performance canvas. It simplifies the design process by reducing performance uncertainty and enables the creation of circuits and antennas that perform reliably from prototype through high-volume production. When your design priorities include signal integrity, bandwidth, and real-world reliability, the 30mil RO4533 laminate stands as a proven, performance-optimized foundation.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com