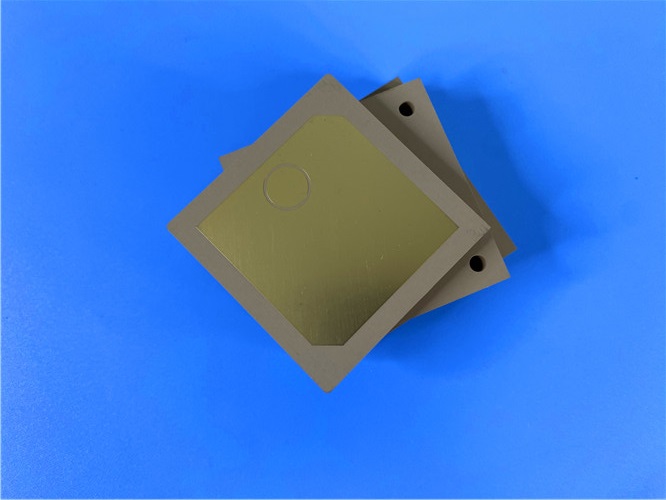

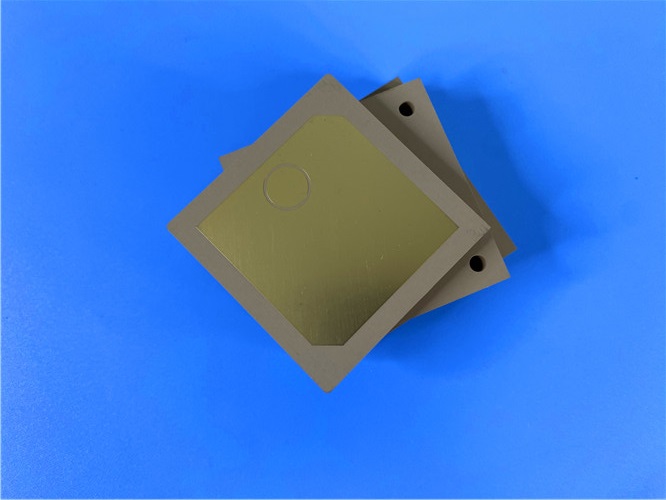

How Does the TP600 Material Ensure Stable Performance in Aerospace and Defense Applications?

In the unforgiving environments of aerospace and defense—from the vacuum of space to the intense heat and vibration inside a missile—electronic failure is not an option. Performance stability is paramount. TheTP600 high-frequency circuit board material is engineered specifically to deliver this critical reliability. Here’s a detailed breakdown of how its inherent properties guarantee stable performance in these demanding applications.

1. Unmatched Electrical Stability Across Extreme Temperature Ranges

Aerospace and defense systems operate across vast temperature swings (e.g., -55°C to +125°C+). Standard materials can experience significant shifts in their Dielectric Constant (Dk), causing impedance drift and signal distortion.

TP600's Solution: It boasts an exceptionally low Thermal Coefficient of Dk (TCDk) of -50 ppm/°C. This means its electrical properties remain remarkably stable with temperature changes. A circuit designed at 25°C will behave almost identically at -55°C or +150°C, ensuring consistent signal speed, impedance, and filter characteristics for radar, guidance, and communication systems.

2. Ultra-Low Signal Loss for Maximum Efficiency and Range

Signal integrity is crucial. High signal loss (dissipation) weakens transmissions, reduces sensor sensitivity, and generates excess heat.

TP600's Solution: It has an ultra-low Dissipation Factor (Df) of 0.0010 at 10 GHz. This minimal loss tangent ensures that RF/microwave signals experience very little attenuation as they travel across the PCB. This translates to:

-

Longer range for communication and radar.

-

Higher efficiency for power amplifiers.

-

Greater sensitivity for receiving systems.

-

Reduced thermal management challenges.

3. Exceptional Mechanical and Dimensional Stability

Thermal cycling, vibration, and shock can cause standard PCB materials to expand/contract at different rates than mounted components, leading to solder joint fatigue, delamination, and failure.

TP600 high frequency PCB's Solution: It features a matched and low Coefficient of Thermal Expansion (CTE): 50 ppm/°C in X and Y axes, and 60 ppm/°C in the Z-axis. This CTE is much closer to that of copper and typical ceramic components than standard FR-4. This close matching minimizes stress during temperature cycles, dramatically enhancing the long-term mechanical reliability of solder joints and plated through-holes under vibration and shock.

4. Superior Resistance to Harsh Environmental Conditions

These systems face moisture, chemicals, and require outstanding flame retardancy.

TP600's Solution:

Near-Zero Moisture Absorption (0.01%): Water is a major enemy of electrical stability, as it alters the Dk and increases loss. TP600's ceramic-PPO composite is virtually non-hygroscopic, ensuring its electrical performance remains unchanged in humid environments or after exposure.

UL 94-V0 Flammability Rating: It meets the highest standard for flame retardancy, a critical safety requirement in enclosed aerospace and vehicle systems.

Robust Base for ENEPIG Finish: The ENEPIG surface finish provides a hermetic, corrosion-resistant barrier, protecting the copper from oxidation and ensuring reliable solderability and wire bonding over years of storage or operation.

5. Material Homogeneity and Process Compatibility

The TP600 PCB material is reinforcement-free (no fiberglass weave). This eliminates the localized variations in Dk and the potential for "fiber weave effect" that can cause signal integrity issues at high frequencies. Its homogeneous structure ensures predictable, uniform performance across the entire board. Furthermore, it is compatible with standard PCB fabrication and assembly processes (like the ENEPIG finish used on this board), allowing for reliable manufacturing.

Conclusion: A System-Level Foundation for Reliability

In aerospace and defense applications, the PCB substrate is not just a carrier for components; it is a foundational element of the system's performance and survivability. The TP600 PCB substrate ensures stable performance by acting as a passive, predictable, and robust platform:

-

Electrically Stable with temperature and frequency.

-

Mechanically Robust against thermal and physical stress.

-

Environmentally Inert against moisture and heat.

-

Manufacturably Reliable with high-quality finishes.

For mission-critical systems like missile guidance, fuze electronics, satellite navigation modules, and miniaturized airborne antennas, specifying a TP600-based PCB, such as the 19.6mil 2-layer ENEPIG board, mitigates risk at the material level and provides engineers with a trustworthy foundation upon which to build systems that must perform perfectly, every time, under extreme conditions.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com