As technology continues to advance, the demand for high-performance electronics continues to grow. Hybrid PCBs have emerged as a solution to this demand, offering a unique combination of different PCB technologies that allow for higher performance and functionality. In this essay, we will explore the benefits and applications of hybrid PCBs, and how they can revolutionize the electronics industry.

What are Hybrid PCBs?

Hybrid PCBs are a combination of different PCB technologies, such as rigid and flexible PCBs or multilayer and single layer PCBs. This allows for the integration of multiple functions and components into a single PCB, increasing functionality and reducing the need for multiple PCBs.

Benefits of Hybrid PCBs

Hybrid PCBs offer many benefits over traditional PCBs, including:

1. Increased functionality: By combining different PCB technologies, hybrid PCBs can offer a wider range of functions and components in a single board. This reduces the need for multiple PCBs and simplifies the assembly process.

2. Improved reliability: Hybrid PCBs can be designed to meet specific performance requirements, ensuring reliability and durability in harsh environments.

3. Reduced size and weight: By integrating multiple functions into a single board, hybrid PCBs can reduce the size and weight of electronic devices, making them more portable and convenient.

4. Enhanced performance: Hybrid PCBs can offer improved performance over traditional PCBs, particularly in high-frequency and high-speed applications.

Applications of Hybrid PCBs

Hybrid PCBs have numerous applications across various industries, including:

1. Medical devices: Hybrid PCBs can be used in medical devices, such as pacemakers and implantable devices, to improve functionality and reduce size and weight.

2. Aerospace and defense: Hybrid PCBs can be designed to meet specific performance requirements in aerospace and defense applications, such as communication and guidance systems.

3. Automotive: Hybrid PCBs can be used in automotive applications, such as advanced driver assistance systems, to improve functionality and performance.

4. Consumer electronics: Hybrid PCBs can be used in consumer electronics, such as smartphones and tablets, to reduce size and weight and improve performance.

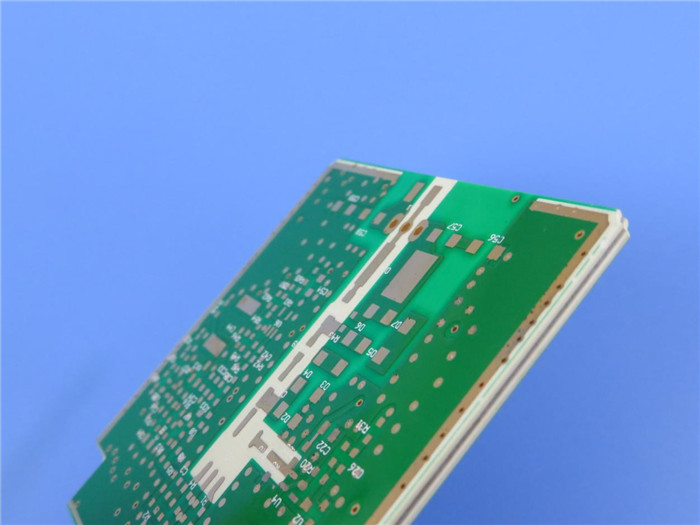

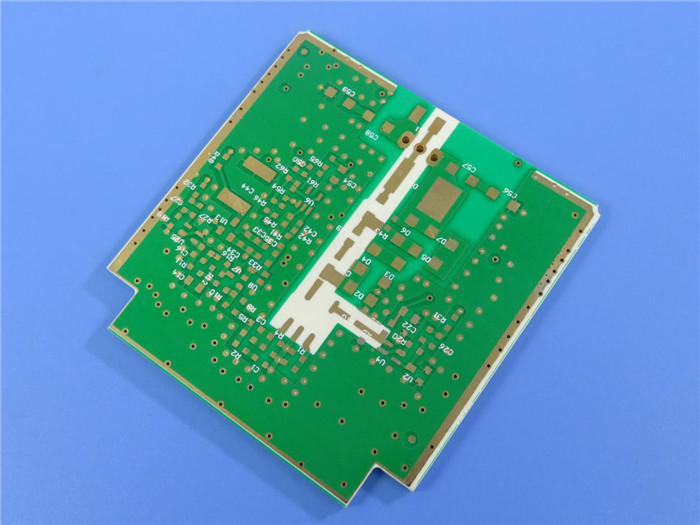

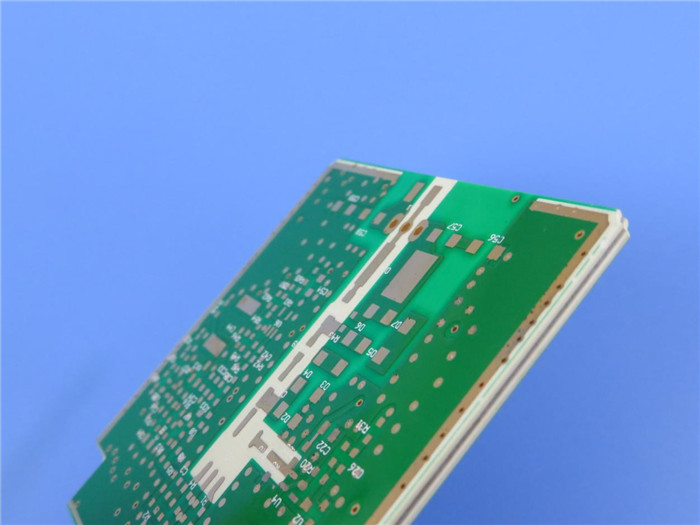

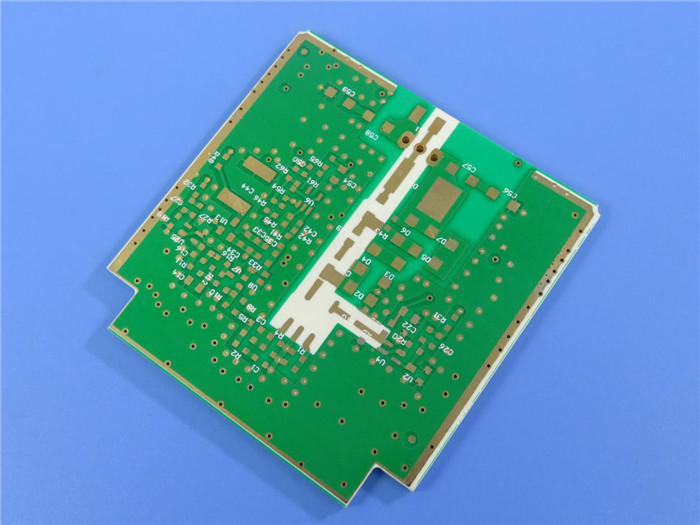

There is our typical hybrid PCBs for your reference.

Hybrid PCB Mixed Circuit Board Hybrid Design RO4350B+FR4 With Immersion Gold RO4350B+RT/duroid 5880 with Blind via

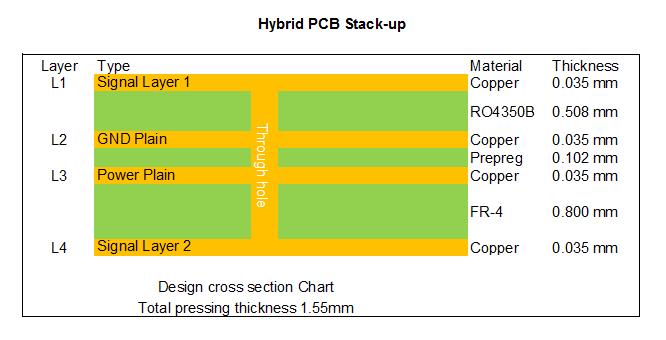

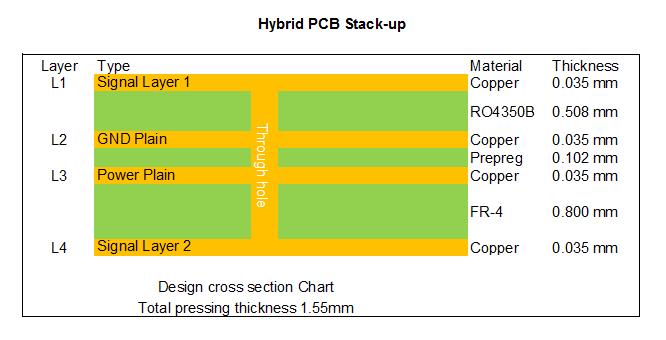

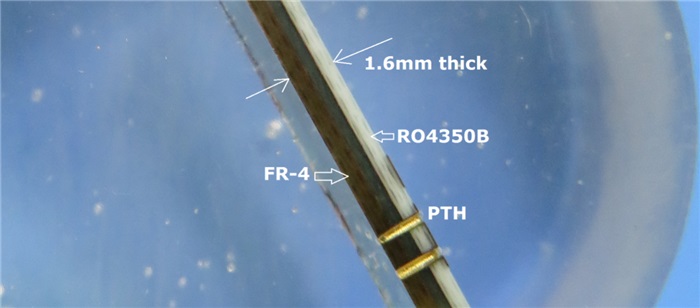

Let’s see the stack-up to get idea about hybrid structure.

Layer 1 to layer 2 is the core of RO4350B high frequency material and layer 3 to layer 4 is the core of FR-4 epoxy glass. The 2 cores are bonded by a sheet of adhesive (prepreg).

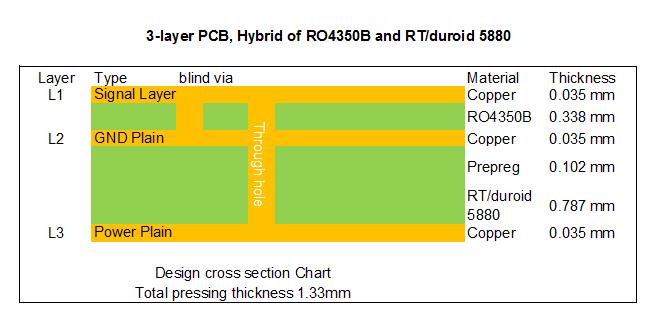

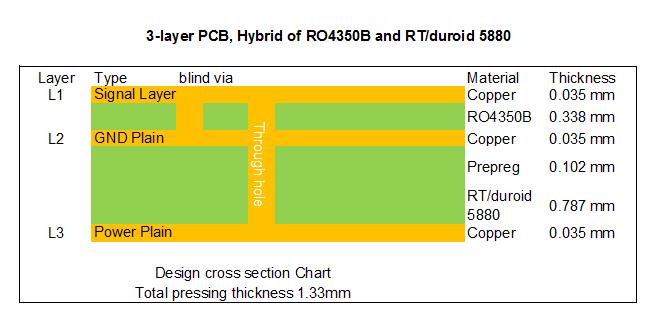

Types of hybrid PCB

The hybrid PCB can be a mixture of FR-4 and high frequency material as abovementioned, another type is a mixture of high frequency material with different dielectric constant (DK), for example hybrid RT/duroid 5880 and RO4350B PCB etc.

Why do we use hybrid PCB?

There're 3 main reasons that convince us to use this type of high frequency multilayer PCB, i.e. cost, reliability improved and electrical properties enhanced.

The cost of high frequency material is much higher than FR-4, sometimes, when using hybrid of FR-4 and high frequency material can solve the cost problem.

It causes reliability problems when the CTE value of the PCB material used is relatively high, while some high frequency materials have high CTE characteristics. When a low CTE FR-4 material is combined with a high CTE material to make a multilayer board, the composite CTE is acceptable, thus enhancing reliability.

Most of the time, some lines of the mixed PCB board require very high electrical performance, some do not require high, in this case, the parts with low electrical performance requirements will be used FR4, while the parts with high electrical performance requirements will use more expensive high frequency materials. Some using different DK of material to make mixed PCB, it is also to improve electrical properties, such as in some applications of combiners and filters, using different values of DK material.

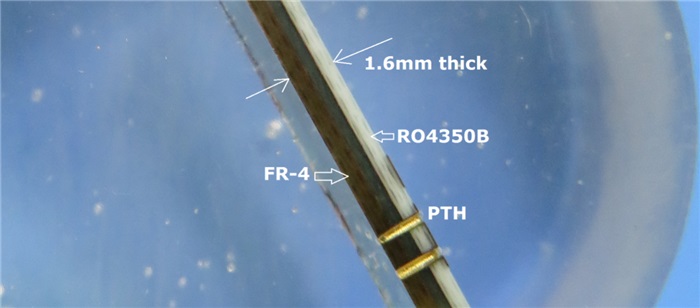

Micro-section of a hybrid PCB

Why choose FR-4?

Mixture of FR-4 and high frequency materials is becoming more and more common because FR-4 and the vast majority of high frequency materials have little compatibility problems.

Lamination

To get a reliable lamination, we first choose PP sheet of high frequency material and use the correct pressing cycle. The adhesive layer of the same material is more favorable for the simpler pressing cycle.

Our PCB Capability(Hybrid PCB)

|

PCB Type:

|

Hybrid PCB, Mixed PCB

|

|

Mixed type:

|

RO4350B + FR4;

|

|

RO4003C + FR4;

|

|

F4B + FR4;

|

|

RT/duroid5880 + FR4;

|

|

RT/duroid5880 + RO4350B

|

|

Solder mask:

|

Green, Red, Blue, Black, Yellow

|

|

Layer count:

|

4 Layer, 6 Layer, Multilayer

|

|

Copper weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

1.0-5.0mm

|

|

PCB size:

|

≤400mm X 500mm

|

|

Surface finish:

|

Bare copper, HASL, ENIG, Immersion tin, OSP

|

In conclusion, hybrid PCBs offer numerous benefits over traditional PCBs, including increased functionality, improved reliability, reduced size and weight, and enhanced performance. Their applications across various industries, including medical devices, aerospace and defense, automotive, and consumer electronics, make them a critical component of the electronics industry. As technology continues to advance, the future of hybrid PCBs looks bright, and they are sure to play a key role in the development of high-performance electronics.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com