Rogers RO4003C is an advanced PCB material that has gained popularity in recent years due to its exceptional properties and advantages over other materials. This article will explore the benefits and versatility of Rogers RO4003C PCB for different applications, and provide tips for optimizing your PCB design with this material.

Introducing our latest PCB, built with high-quality materials and advanced construction techniques, the perfect solution for your circuit board needs. With its superior specifications and reliable performance, this PCB is an excellent choice for a wide range of applications.

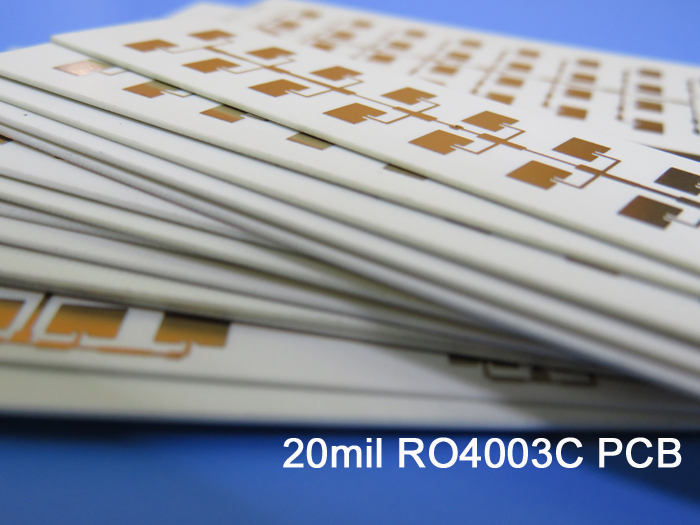

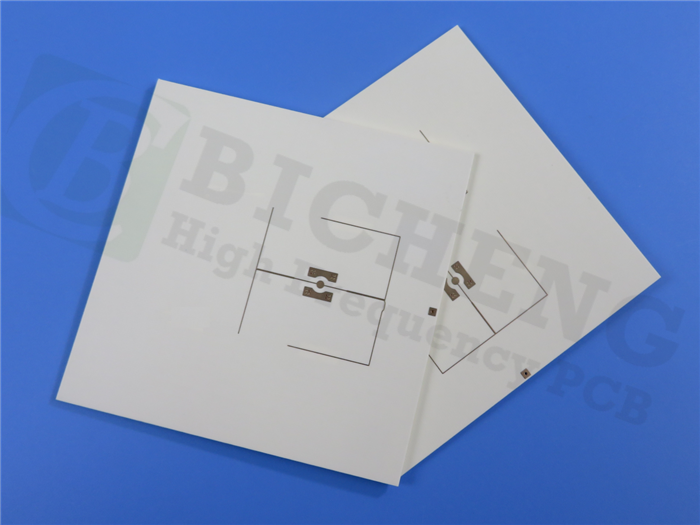

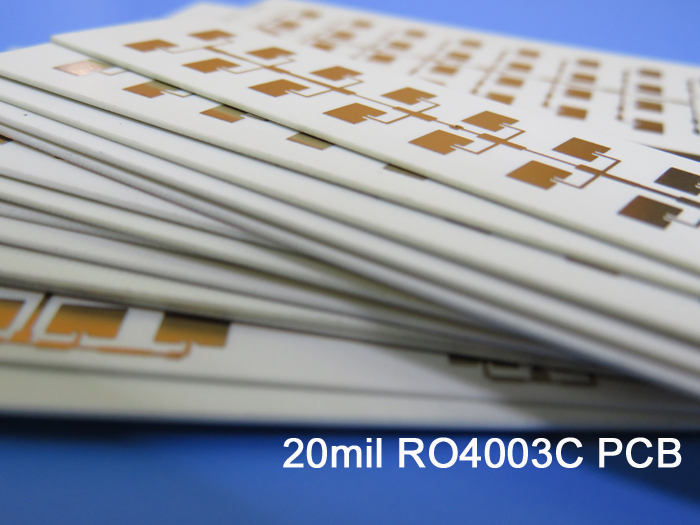

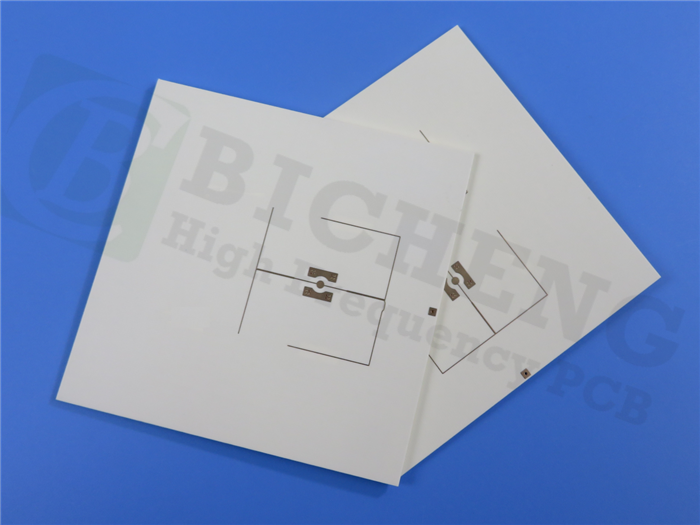

Constructed with 20mil Rogers RO4003C material and processed using a lead-free method, this PCB is capable of operating between temperatures of -40℃ to +85℃, making it a durable and reliable choice for a variety of applications. The double-sided stackup features a base copper weight of 35um and 0.508mm RO4003C substrate dielectric of 20mil , ensuring excellent signal integrity and low loss characteristics.

The board dimensions of 144mm x 155mm (with a tolerance of +/- 0.15mm) and minimum trace/space of 11/12 mils make it a highly versatile option for a broad range of projects. The minimum hole size of 0.5mm and 61 vias make it a highly adaptable PCB, while the finished board thickness of 0.68mm and finished copper weight of 1.5 oz (2.1 mils) all layers provide a robust and sturdy construction.

The PCB features a surface finish of Electroless Nickel and Immersion Gold (ENIG) for excellent protection against oxidation and corrosion. The top solder mask is green, while the bottom solder mask is uncoated. Additionally, all Vias are filled by resin and capped, ensuring exceptional durability and long-term performance.

Our PCB also includes a 100% electrical test, ensuring that you receive a PCB that meets the highest standards of quality and performance. With 21 components, 32 total pads, 23 thru-hole pads, 9 top SMT pads, 0 bottom SMT pads, and 9 nets, this PCB is highly versatile and adaptable to a variety of applications.

For any technical questions or inquiries, please do not hesitate to contact our sales representative, Jane, at sales20@bichengpcb.com. We are confident that our latest PCB will meet your expectations and exceed your needs.

Introduction to Rogers RO4003C PCB Material

Rogers RO4003C PCB is a high-performance PCB material that offers superior electrical, thermal, and mechanical properties. It is a ceramic-filled hydrocarbon laminate with a dielectric constant of 3.38, making it ideal for high-frequency and high-speed applications. It also has a low dissipation factor of 0.0027, which reduces signal losses and improves signal integrity.

Advantages of Using Rogers RO4003C for High-Frequency and High-Speed Applications

Rogers RO4003C is an excellent choice for high-frequency and high-speed applications due to its low signal loss, high thermal stability, and excellent electrical properties. It offers a low insertion loss and excellent phase stability up to 40 GHz, making it ideal for high-frequency circuits. It also has a high glass transition temperature (Tg) of >280°C, which ensures excellent thermal stability and reliable performance even under harsh conditions.

Benefits of Lead-Free Process with Rogers RO4003C PCB Material

Rogers RO4003C is processed using lead-free technology, which makes it environmentally friendly and compliant with RoHS regulations. It also provides a safer working environment for operators and reduces the risk of contamination. The lead-free process does not compromise the material's electrical or mechanical properties, making it an ideal choice for high-reliability applications.

Understanding the Dielectric Constant and Dissipation Factor of Rogers RO4003C

The dielectric constant and dissipation factor are essential parameters for high-frequency and high-speed applications. Rogers RO4003C has a low dielectric constant of 3.38, which reduces the propagationdelay and crosstalk in high-frequency circuits. Its low dissipation factor of 0.0027 ensures minimal signal losses and excellent signal integrity, making it an ideal choice for RF and microwave applications.

Thermal Properties of Rogers RO4003C: Coefficient of Thermal Expansion and Thermal Conductivity

Rogers RO4003C has a low coefficient of thermal expansion (CTE) of 11 ppm/°C in the X direction and 14 ppm/°C in the Y direction, which ensures excellent dimensional stability even under extreme thermal conditions. It also has a high thermal conductivity of 0.71 W/m/°C, which facilitates heat dissipation and improves the overall thermal management of the PCB.

Mechanical Properties of Rogers RO4003C: Tensile and Flexural Strength, Copper Peel Strength

Rogers RO4003C has excellent mechanical properties, including high tensile and flexural strength, and copper peel strength. Its tensile strength is 139 MPa in the X direction and 100 MPa in the Y direction, while its flexural strength is 276 MPa. It also has a copper peel strength of 1.05 N/mm after solder float with 1 oz EDC foil.

Electrical Properties of Rogers RO4003C: Electrical Strength, Volume and Surface Resistivity

Rogers RO4003C has excellent electrical properties, including high electrical strength, and volume and surface resistivity. Its electrical strength is 31.2 kV/mm (780 V/mil), and its volume resistivity is 1.7 x 10^10 MΩ.cm. Its surface resistivity is 4.2 x 10^9 MΩ, making it an ideal choice for high-voltage applications.

Applications of Rogers RO4003C PCB Material in Different Industries

Rogers RO4003C is a versatile PCB material that finds applications in various industries, including aerospace, automotive, telecommunications, and medical devices. Its superior properties make it an ideal choice for high-reliability applications, such as radar systems, satellite communication, and medical imaging.

Comparing Rogers RO4003C with Other PCB Materials: Why Choose RO4003C?

Compared to other PCB materials, Rogers RO4003C material offers superior electrical, thermal, and mechanical properties, making it an excellent choice for high-performance applications. Its low dielectric constant, low dissipation factor, and high thermal stability make it ideal for high-frequency and high-speed circuits. Its lead-free process makes it environmentally friendly and compliant with RoHS regulations.

Tips for Optimizing Your PCB Design with Rogers RO4003C

To get the most out of Rogers RO4003C in your PCB design, consider the material's properties and characteristics, such as its dielectric constant, dissipation factor, thermal conductivity, and CTE. Also, optimize your design for signal integrity and thermal management, and follow best practices for PCB layout and manufacturing.

Conclusion

Rogers RO4003C is an advanced PCB material that offers exceptional properties and advantages over other materials. Its low signal loss, high thermal stability, and excellent electrical properties make it an ideal choice for high-frequency and high-speed applications. Its lead-free process makes it environmentally friendly and compliant with RoHS regulations. By optimizing your PCB design with Rogers RO4003C, you can improve signal integrity and performance and ensure reliable operation in high-reliability applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com