Multilayer Stackup Design: Minimizing Crosstalk in High-Speed PCBs

Introduction

In high-speed PCB design, signal integrity is paramount. As data rates increase, crosstalk—unwanted electromagnetic coupling between traces—becomes a critical challenge. A well-optimized multilayer stackup is essential to minimize crosstalk while ensuring signal integrity, power delivery, and manufacturability.

This article explores how to design a 6-layer PCB stackup for high-speed applications, using our RO4350B + S1000-2M construction as a case study. We’ll examine material selection, layer arrangement, impedance control, and design techniques to reduce crosstalk.

Understanding Crosstalk in High-Speed PCBs

Crosstalk occurs when signals on adjacent traces interfere due to capacitive (electric field) and inductive (magnetic field) coupling. Key factors influencing crosstalk include:

-

Trace spacing & parallelism–Closer traces increase coupling.

-

Reference plane proximity–A solid ground plane reduces interference.

-

Signal layer arrangement–Poor stackup design exacerbates crosstalk.

-

Dielectric material properties–Lower Dk and Df materials help reduce coupling.

A well-designed 6-layer hybrid PCB stackup can mitigate these issues by providing:

✔Shielded signal layers

✔Controlled impedance routing

✔Optimized dielectric spacing

Case Study: 6-Layer High-Speed PCB Stackup

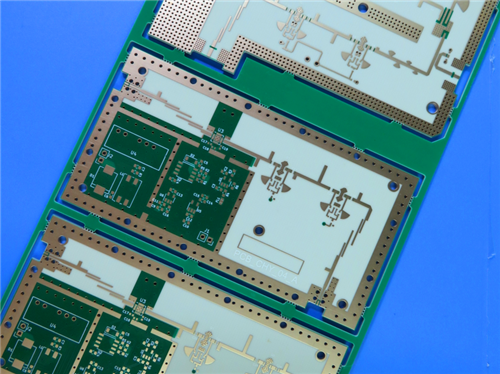

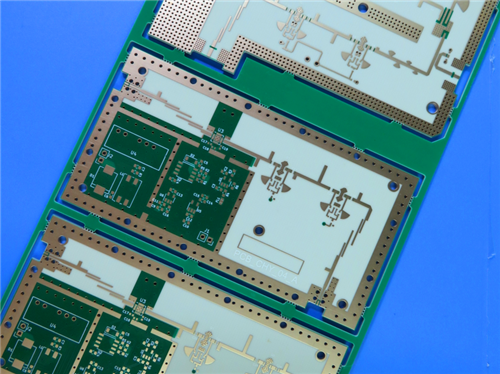

Our 6-layer PCB (76.5mm x 83mm) is designed for high-speed applications with RO4350B microwave laminate and S1000-2M high-Tg FR4.

PCB Stackup Breakdown

|

Layer

|

Material

|

Thickness

|

Function

|

|

L1

|

Copper (35μm)

|

-

|

Signal (Top Layer, 50Ω impedance)

|

|

PP1

|

RO4350B

|

0.254mm

|

Low-loss dielectric

|

|

L2

|

Copper (35μm)

|

-

|

Ground Plane

|

|

PP2

|

Prepreg (1080)

|

0.127mm

|

Bonding layer

|

|

L3

|

Copper (35μm)

|

-

|

Signal (Internal High-Speed)

|

|

Core

|

S1000-2M

|

0.254mm

|

High-Tg FR4 for stability

|

|

L4

|

Copper (35μm)

|

-

|

Power Plane

|

|

PP3

|

Prepreg (1080)

|

0.127mm

|

Bonding layer

|

|

L5

|

Copper (35μm)

|

-

|

Signal (Internal High-Speed)

|

|

PP4

|

RO4350B

|

0.254mm

|

Low-loss dielectric

|

|

L6

|

Copper (35μm)

|

-

|

Signal (Bottom Layer, 50Ω impedance)

|

Key Features for Crosstalk Reduction

1. Rogers RO4350B for Critical Signal Layers

-

Low Dk (3.48) & Df (0.0037) minimizes signal loss and coupling.

-

CTE-matched to copper prevents via reliability issues.

2. ShengyiS1000-2M Core for Mechanical Stability

-

High Tg (180°C) & low Z-CTE ensures thermal reliability.

-

Anti-CAF performance prevents conductive anodic filamentation.

3.Impedance Control (50Ωon Top Layer)

-

4mil trace width with ENIG finish ensures consistent impedance.

4.Shielding with Ground & Power Planes

-

L2 (Ground) & L4 (Power) isolate high-speed signals (L1, L3, L5, L6).

5.Blind Vias (L1-L2) for Signal Integrity

-

Reduces stub effects in high-speed signal transitions.

Design Techniques to Minimize Crosstalk

1. 3W Rule for Trace Spacing

Keep spacing≥3x trace width (e.g., 12mil spacing for 4mil traces).

2. Differential Pair Routing

Maintain consistent spacing & length matching to reduce EMI.

3. Avoid Parallel Routing on Adjacent Layers

Orthogonal routing (90°angles) reduces capacitive coupling.

4. Use Ground-Filled Areas Between Signals

Additional copper pours act as shields.

5. Controlled Dielectric Thickness

Thinner prepreg (0.127mm) reduces crosstalk between layers.

Why This Stackup Works for High-Speed Designs?

✅Low-Loss Materials (RO4350B)→Better signal integrity at GHz frequencies.

✅Solid Ground/Power Planes→Shields high-speed signals.

✅Blind Vias & Impedance Control→Minimizes reflections & EMI.

✅Thermally Stable Core (S1000-2M)→Ensures reliability in harsh conditions.

Applications of This PCB Design

-

5G & Millimeter-Wave Circuits

-

Radar & Satellite Communication Systems

-

High-Speed Digital Boards (FPGA, DDR4/5)

-

RF Antennas & Microwave Circuits

Conclusion

A well-optimized multilayer stackup is critical for minimizing crosstalk inhigh-speed PCBs. By using low-loss materials (RO4350B), proper shielding, and controlled impedance routing, this 6-layer hybrid circuit board design ensures signal integrity while meeting IPC-Class-2 standards.

For high-frequency, high-speed, or RF applications, our RO4350B + S1000-2M stackup provides an ideal balance of performance, reliability, and cost-effectiveness.

Need a custom high-speed PCB solution? Contact us today for expert design and manufacturing support!

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com