PTFE Materials Are Difficult to Process—How to Solve Lamination and Drilling Challenges?

Introduction

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon (TFE), is a high-performance material widely used in printed circuit boards (PCBs) for high-frequency applications. Its low dielectric constant (Dk) and dissipation factor (Df) make it ideal for RF, microwave, and millimeter-wave circuits. However, TFE materials like Rogers RT/duroid 5880 present significant challenges in lamination and drilling due to their unique properties.

In this article, we’ll explore the key difficulties in TFE material PCB fabrication and provide practical solutions to overcome them. We’ll also highlight how our 3-layer rigid PCB with RTduroid 5880 and RO4450F bonding ply successfully addresses these challenges while maintaining high-frequency performance.

Why TFE Materials Are Difficult to Process

PTFE-based laminates like RT/duroid 5880 offer outstanding electrical properties, including:

-

-Low dielectric constant (Dk = 2.2±0.02)

-

-Ultra-low dissipation factor (Df = 0.0009 at 10 GHz)

-

-Excellent thermal stability

However, these benefits come with manufacturing challenges:

1. Lamination Difficulties

-

-Poor Adhesion: PTFE is inherently non-sticky, making it difficult to bond with copper layers.

-

-Thermal Expansion Mismatch: PTFE has a higher coefficient of thermal expansion (CTE) than copper, leading to potential delamination.

-

-Resin Flow Control: Excessive heat and pressure can cause resin squeeze-out, affecting dielectric thickness.

2. Drilling Challenges

-

-Material Softness: PTFE is soft and prone to smearing during drilling, leading to poor via quality.

-

-Thermal Sensitivity:Excessive heat from drilling can degrade PTFE’s electrical properties.

-

-Hole Wall Roughness: Improper drilling can result in rough via walls, affecting signal integrity.

Solutions for Successful TFE PCB Fabrication

1. Optimizing Lamination for TFE Materials

a) Use Special Bonding Materials

To improve adhesion, we use RO4450F bonding ply—a thermoset material compatible withPTFE laminates. In our 3-layer PCB stackup, RO4450F ensures strong interlayer bonding while maintaining electrical performance.

Our PCB Stackup Example:

Layer 1: Copper (35μm)

Core: RT/duroid 5880 (1.575 mm)

Layer 2: Copper (35μm)

Bonding Ply: RO4450F (0.102 mm)

Core: RT/duroid 5880 (1.575 mm)

Layer 3: Copper (35μm)

b) Controlled Lamination Parameters

-

Temperature & Pressure: Precise control prevents resin flow issues and maintains consistent dielectric thickness.

-

Slow Ramp-Up Rates: Gradual heating minimizes thermal stress, reducing delamination risks.

2. Overcoming Drilling Challenges

a) Specialized Drill Bits & Parameters

-

Carbide Drill Bits: Harder than standard drills, reducing PTFE smearing.

-

Optimized RPM & Feed Rate: Prevents excessive heat buildup.

b) Laser Drilling for Micro-Vias

-

For smaller holes (0.4mm in our PCB), laser drilling provides cleaner, more precise vias with minimal wall roughness.

c) Post-Drilling Treatments

-

Plasma Etching: Removes PTFE residue from via walls.

-

Via Plating (20μm in our PCB): Ensures reliable electrical connections.

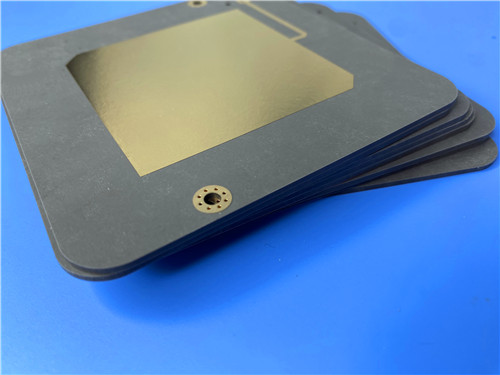

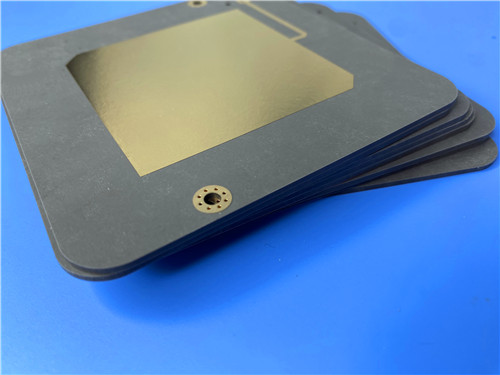

Case Study: Our 3-Layer RT/duroid 5880 PCB

To demonstrate successful TFE material processing, here’s a breakdown of our high-frequency PCB solution:

Key Specifications:

Material: RT/duroid 5880 (core) + RO4450F (bonding ply)

Layers: 3

Board Thickness: 3.3 mm

Min Trace/Space: 5/7 mils

Min Hole Size: 0.4 mm

Via Plating Thickness: 20μm

Surface Finish: Immersion Gold (enhances signal integrity)

Why This Design Works for High-Frequency Applications?

✔Low Signal Loss: RT/duroid 5880’s ultra-low Df ensures minimal RF attenuation.

✔Stable Dk: Uniform dielectric constant across frequencies.

✔Robust Construction: RO4450F bonding ply prevents delamination.

✔Precision Drilling: 0.4mm vias with 20μm plating ensure reliable interconnects.

Conclusion: Partner with a PCB Supplier Experienced in TFE Materials

Fabricating High Frequency PTFE PCB with RT/duroid 5880 and other PTFE-based materials requires specialized expertise in lamination, drilling, and thermal management. By optimizing bonding materials, drilling techniques, and lamination processes, we deliver high-performance PCBs for RF, aerospace, and millimeter-wave applications.

Looking for a reliable TFE PCB supplier? Our 3 Layer High Frequency PCB RT/duroid 5880 is IPC-Class-2 compliant, electrically tested, and available worldwide. Contact us today for high-frequency PCB solutions tailored to your needs!

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com