Rogers RO3203 laminates with ceramic filling offer enhanced and excellent mechanical qualities. One of the high-frequency applications-focused laminates in the RO3003 series is this one. The RO3203 circuit material has woven glass cloth reinforcements.

As a trustworthy material that satisfies the requirements and standards of designers, this ceramic-filled circuit material has ISO 9002 certification. This laminate was made with a broad frequency range in mind. Many features and advantages are offered by this Rogers PCB material.

These laminates are created with PTFE substrates and woven glass reinforcement. The RO3203 laminates are an enhanced variant of the RO3003 laminates with better mechanical properties. As a result, it is mechanically and electrically similar to RO3003.

Many applications, including as direct broadcast satellites, base station infrastructure, power backplanes, and collision avoidance systems, are ideal for these laminates. The Rogers 3203 PCB was strengthened mechanically by the addition of woven fiberglass. It is utilized in situations where mechanical strength is crucial, which is a key justification.

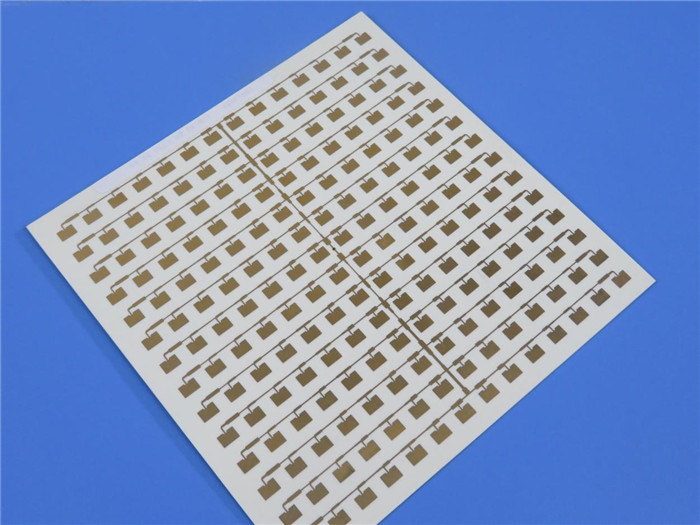

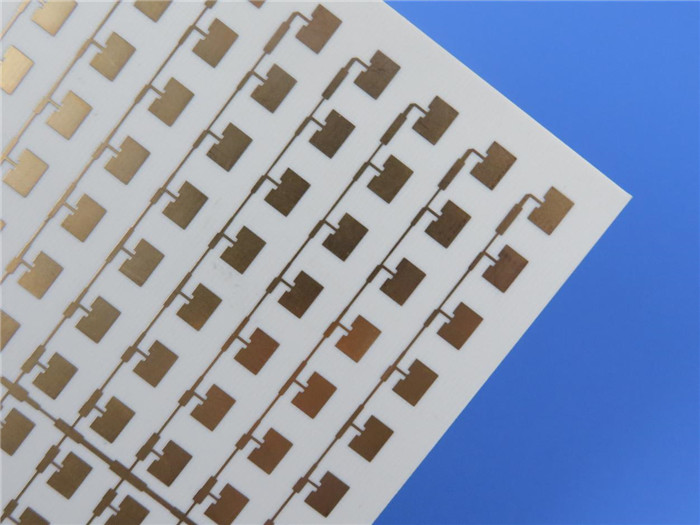

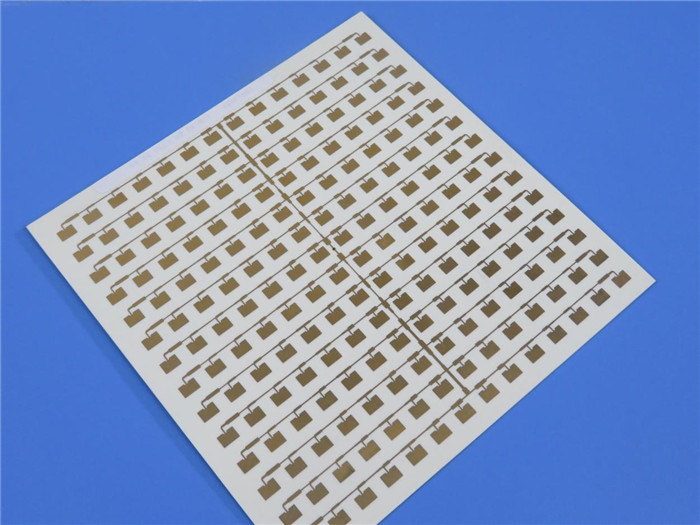

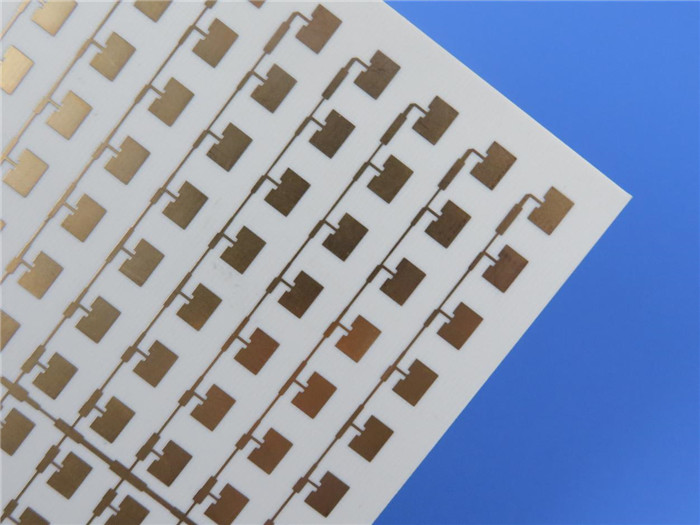

Following is an 20mil Rogers 3203 PCB for reference.

Properties of RO3203

The distinctive features of the Rogers RO3203 set it apart from the RO3000 series. Among its attributes are:

Low coefficient of thermal expansion: The RO3203 material has a 13 ppm/°C coefficient of thermal expansion in both the X and Y axes. It is perfect for use in the creation of multilayer epoxy fiberglass hybrid boards because of its feature.

Poor dimensional stability: The RO3203's dimensional stability is 0.8 mm/m. It is thought that this dimensional stability is very low. No of the environmental circumstances, this material can keep its size.

This material has a dielectric constant of 3.02, which is excellent. With a material like Rogers 3203, this number is thought to be optimum. High-frequency applications are best suited for materials with low dielectric constants because they reduce the loss of electric power.

Reduced moisture absorption: RO3203 materials only absorb 0.1% of moisture. Designers prefer materials with extremely low levels of moisture absorption. The material's thermal and electrical properties will be largely unaffected by low moisture absorption.

Advantages of RO3203

The several advantages that Rogers RO3203 provides set them apart from the RO3000 series. These laminates have advantages such;

-

Copper surface that is smooth and allows for tighter line tolerances

-

It has excellent stiffness and is quite manageable.

-

low copper-compatible in-plane expansion

-

Various dielectric constants

-

Standardized mechanical and electrical characteristics

-

Remarkably high dimensional stability

-

Cost-effective

Applications of Rogers RO3203

RO3203 circuit materials are used for high frequencies that are up to 20 GHZ. These materials are used for a wide range of applications which include:

-

Base stations infrastructure

-

Direct broadcasts satellites

-

Systems for datalinks on cables

-

Power backplanes

-

Remote meter reader

-

Automotive global positioning system antennas

-

Patch antennas for wireless communication

-

Wireless and LMDS broadband

Considerations for selecting Rogers RO3203

When choosing RO3203, there are a number of aspects to take into account, such factors being:

Application requirements: It's critical that this material's electrical and mechanical qualities satisfy your application's needs.

Availability is an important issue that should be taken into account. Make sure to check with your supplier to see whether they have enough RO3203 laminates on hand.

Tolerance for thickness: RO3203 features a tight Dk control range and thickness tolerance. These materials come in a variety of thicknesses to meet the needs of different consumers.

When choosing materials for high-frequency applications, thickness is crucial. The height and weight of the PCB will vary depending on the laminate's thickness.

Copper cladding type: RO3203 is available in a variety of copper cladding variants. However, there are only three main sizes for electrodeposited copper, namely 2 oz (70 m), 1 oz (35 m), and 1/2 ounce (17 m). You can pick the cladding style that best fits your needs.

The purpose of using Rogers RO3203 in RF and microwave applications

A PTFE composite called RO3203 has cutting-edge mechanical and electrical characteristics. Throughout a wide range of temperatures and frequencies, this material maintains a low and steady Dk.

Due to its low Dk of 3.02 and low dissipation factor of 0.0016, this material is a good choice for high-frequency applications. Due to its low moisture absorption, strict Dk control, and thickness tolerance, this material is utilized in RF and microwave applications.

Because of its increased stiffness, it is also perfect for applications that need mechanical stability. The low in-plane and Z-direction expansion of ro3203 makes it a key component in RF and microwave applications.

Conclusion

Rogers 3203 laminates provide outstanding dimensional stability and an optimum coefficient of thermal expansion. Because of the advantages they provide, these laminates have been a prominent material in the market.

RO3203's woven glass reinforcing makes them simple to manufacture. These materials also offer excellent peel strength and a low CTE, making them ideal for thinner laminates. RO3203 also has a low dielectric constant, which aids in maintaining stability across a wide range of frequencies and temperatures.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com