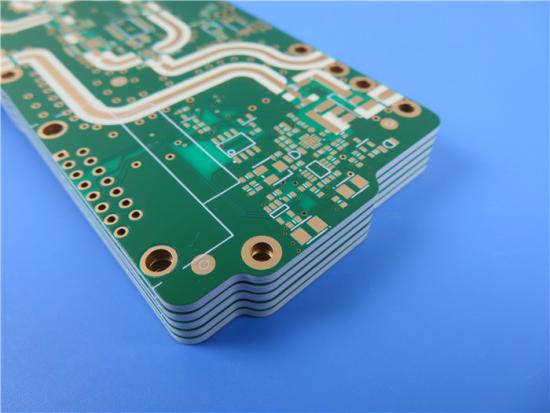

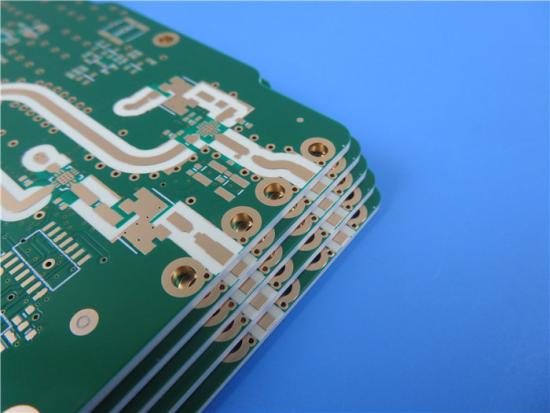

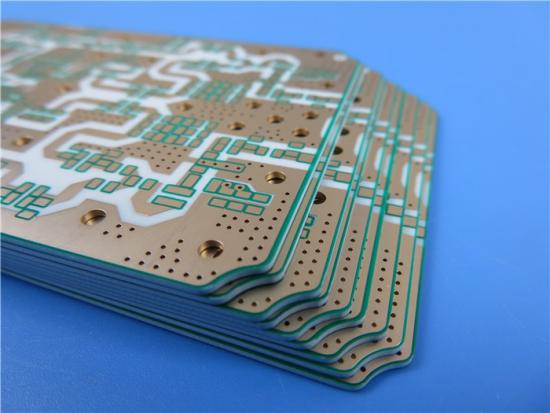

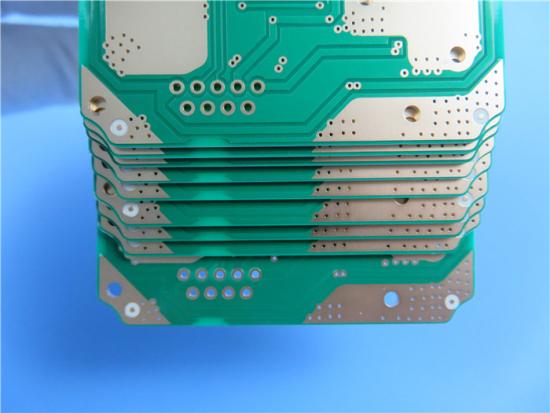

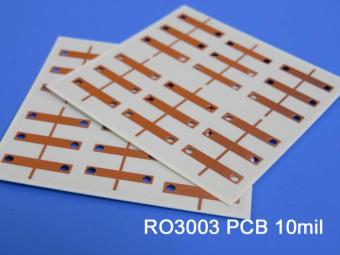

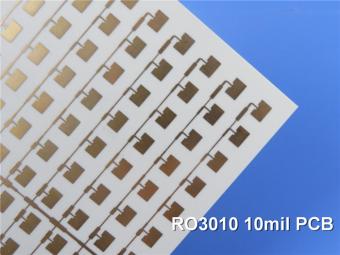

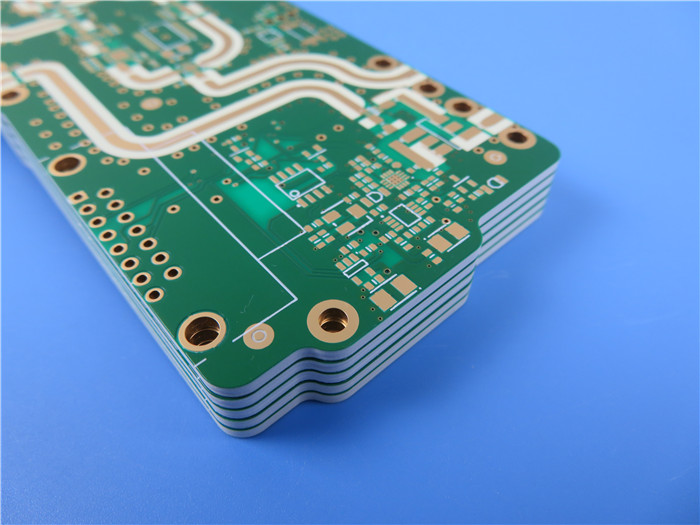

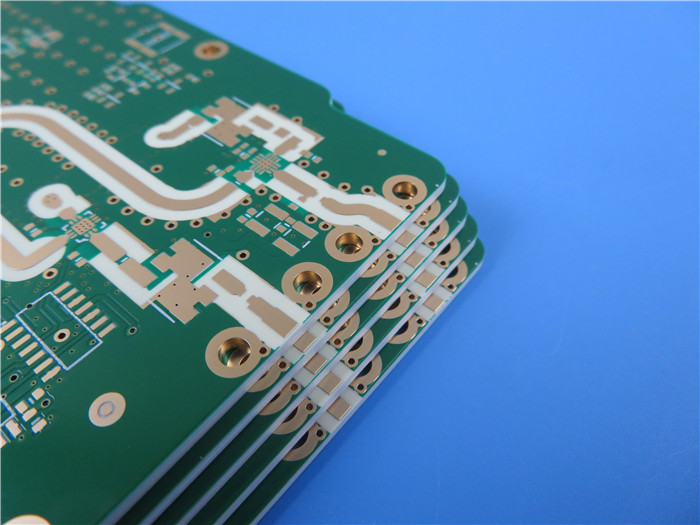

Rogers

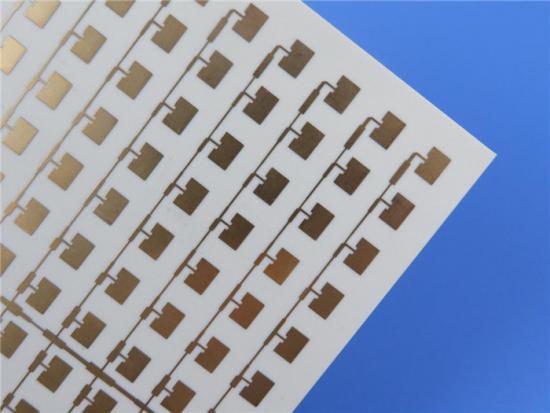

3203 PCB RO3203 High Frequency PCB Double Sided RF Circuit Board For Base

Station Infrastructure

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

This material is engineered to

offer exceptional electrical performance and mechanical stability at

competitive prices. The dielectric constant of RO3203 High Frequency Circuit

Materials is 3.02. This, along with a dissipation factor of 0.0016, extends the

useful frequency range beyond 40 GHz.

Ceramic-filled

laminates like the Rogers RO3203 offer enhanced and superior mechanical

qualities. One of the laminates of the ro3003 family, it is intended for

high-frequency uses. RO3203 is a woven glass cloth-reinforced circuit material.

This

ceramic-filled circuit material has ISO 9002 certification, making it a

dependable product that satisfies the requirements and standards of designers.

This laminate was created primarily to provide a broad frequency range. There

are various features and advantages of using this Rogers PCB material.

The PTFE substrates used to create these laminates are strengthened with woven

glass. To provide greater mechanical qualities, RO3203 laminates are an

enhanced version of RO3003 laminates. As a result, it shares RO3003's

electrical and mechanical characteristics.

Feature

of RO3203:

The

distinctive features of the Rogers RO3203 set it apart from the RO3000 series.

Among its attributes are:

Low

coefficient of thermal expansion: The RO3203 material has a 13 ppm/°C

coefficient of thermal expansion in both the X and Y axes. It is perfect for

use in the creation of multilayer epoxy fiberglass hybrid boards because of its

feature.

Low

dimensional stability: The ro3203's dimensional stability is 0.8 mm/m. It is

thought that this dimensional stability is very low. No of the environmental

circumstances, this material can keep its size.

Excellent

dielectric constant: This material's dielectric constant is 3.02. For a

substance like Rogers 3203, this value is regarded as optimum. Low dielectric

constant materials assist reduce electrical power loss, making them perfect for

high-frequency applications.

Lower

moisture absorption: Materials made of RO3203 have a moisture absorption of

0.1%. Extremely little moisture will absorb at this level, which is ideal for

designers. The thermal and electrical characteristics of the material will be

hardly affected by low moisture absorption.

Typical

Applications:

1.

Automotive Collision Avoidance Systems

2.

Automotive Global Positioning Satellite Antennas

3.

Base Station Infrastructure

4.

Datalink on Cable Systems

5.

Direct Broadcast Satellites

6.

LMDS and Wireless Broadband

7.

Microstrip Patch Antennas

8.

Power Backplanes

9.

Remote Meter Readers

10. Wireless

Telecommunications Systems

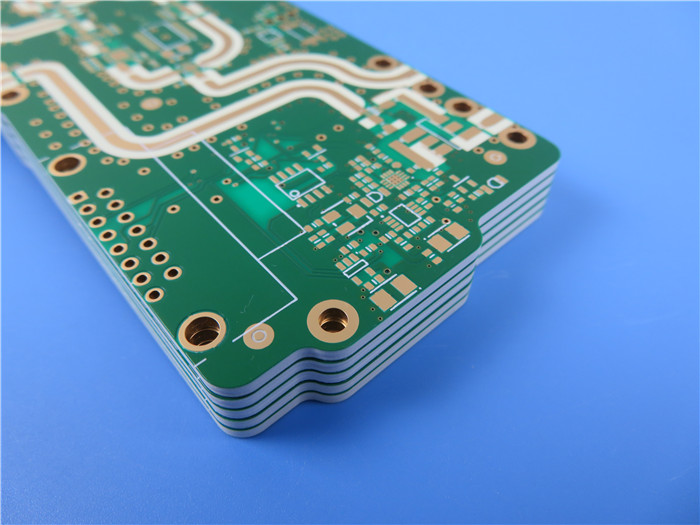

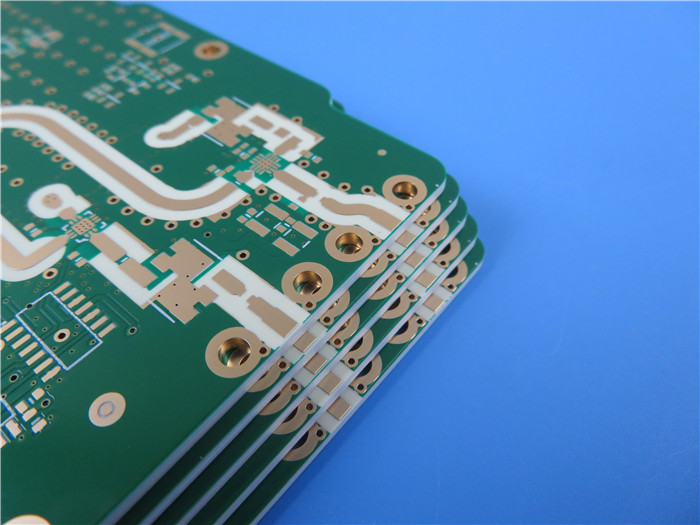

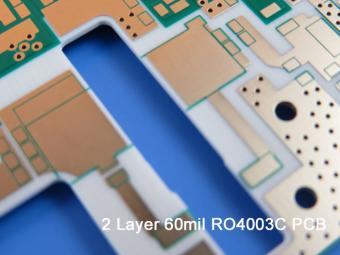

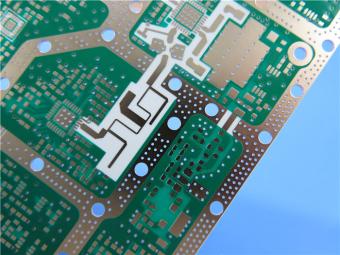

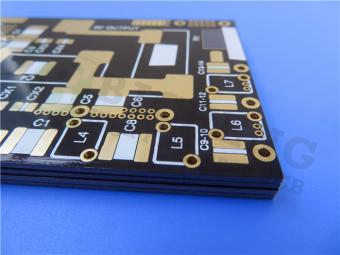

PCB

Capability (RO3203)

|

PCB Capability (RO3203)

|

|

PCB Material:

|

Ceramic-filled Laminates Reinforced

with Woven Fiberglass

|

|

Designation:

|

RO3203

|

|

Dielectric constant:

|

3.02±0.04

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

10mil

(0.254mm), 20mil(0.508mm), 30mil (0.762mm), 60mil(1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG, OSP etc..

|

Data

Sheet of RO3203:

|

RO3203

Typical Value

|

|

Property

|

RO3203

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

3.02±0.04

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5

|

|

Dissipation Factor,tanδ

|

0.0016

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal

Conductivity

|

0.47 (3.2)

|

|

W/mK

|

Float

100℃

|

ASTM C518

|

|

Volume Resistivity

|

107

|

|

MΩ.cm

|

A

|

ASTM D257

|

|

Surface Resistivity

|

107

|

|

MΩ

|

A

|

ASTM D257

|

|

Dimensional Stability

|

0.08

|

X, Y

|

mm/m

+E2/150

|

after etch

|

IPC-TM-650 2.4.3.9

|

|

Tensile Modulus

|

|

X Y

|

kpsi

|

RT

|

ASTM D638

|

|

Flexural Modulus

|

400 300

|

X Y

|

kpsi

|

A

|

ASTM D790

|

|

Tensile Strength

|

12.5 13

|

X Y

|

kpsi

|

RT

|

ASTM D638

|

|

Flexural Strength

|

9 8

|

X Y

|

kpsi

|

A

|

ASTM D790

|

|

Moisure Absorption

|

<0.1

|

|

%

|

D24/23

|

IPC-TM-650 2.6.2.1

|

Coefficient of Thermal Expansion

|

58 13

|

Z X,Y

|

ppm/℃

|

-50℃to

288℃

|

ASTM D3386

|

|

Td

|

500

|

|

℃

|

TGA

|

ASTM D3850

|

|

Density

|

2.1

|

|

gm/cm3

|

23℃

|

ASTM D792

|

|

Copper Peel Stength

|

10 (1.74)

|

|

lbs/in (N/mm)

|

After solder

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-Free Process Compatible

|

Yes

|

|

|

|

|

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com