The FR4 and the Mixing of Rogers Substrate Parameters and Normal Thickness

1. FR-4 substrate parameter classification: dielectric constant parameter, dielectric loss parameter, IG value parameter

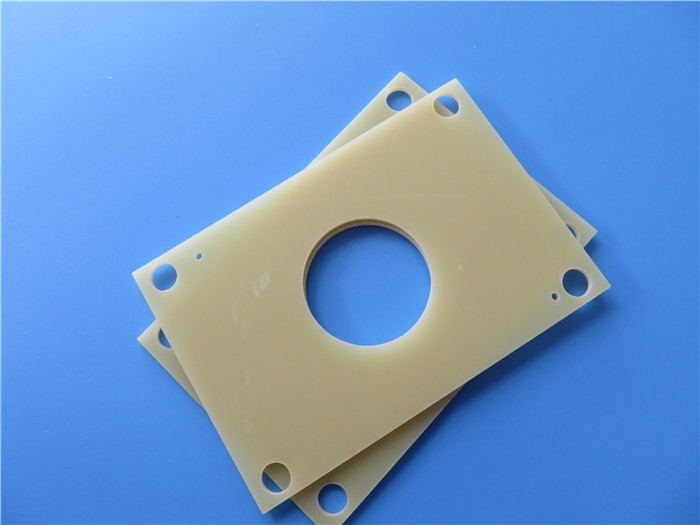

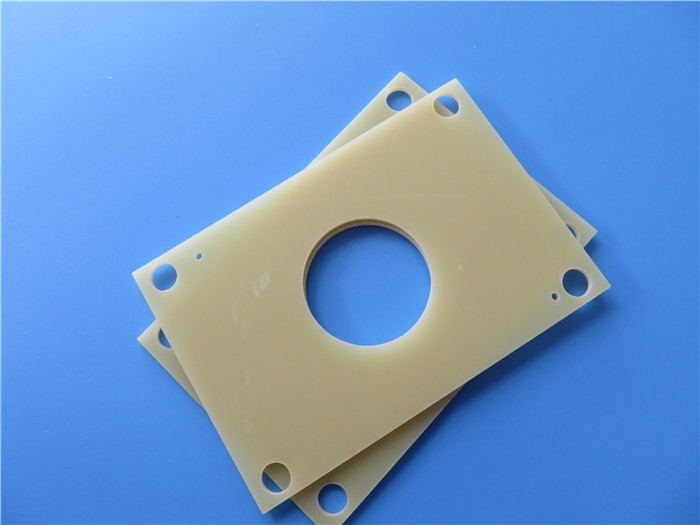

FR-4 susbstrate is made of epoxy resin + glass cloth pressed into a

double-sided FR4 PCB board, - commonly used FR4 copper-coated plate, relative to the air dielectric constant is 4.2-4.7. This permittivity varies with temperature, up to 20% in the temperature range of 0-70 degrees. A change in the dielectric constant causes a 10% change in line delay, and the higher the temperature, the greater the delay. The permittivity also varies with the signal frequency. The higher the frequency is, the smaller the permittivity is. The classical value of permittivity in general design is 4.4.

The permittivity (Dk, ε, Er) determines the speed at which electrical signals propagate in the medium. The speed at which an electrical signal travels is inversely proportional to the square root of the dielectric constant. The lower the permittivity is, the faster the signal is transmitted. As an analogy, if you are running on the beach, the water is up to your ankles, and the viscosity of water is the permittivity. The more viscous the water, the higher the permittivity, the slower you run.

Permittivity is not very easy to measure or define. It is not only related to the characteristics of the medium itself, but also related to the test method, test frequency, and material state before and during the test. Permittivity also varies with temperature, and some special materials are developed with temperature in mind. Humidity is also an important factor in the permittivity of water, because the permittivity of water is 70, and very little water can cause significant changes.

Dielectric loss of FR4 substrate: the energy loss caused by dielectric conductivity and dielectric polarization in insulating materials under the action of electric field. Also called dielectric loss, referred to as dielectric loss. Under the action of alternating electric field, the residual Angle δ of the Angle (in power factor Angle) between the current and voltage phasor flowing in the dielectric is called the dielectric loss Angle. FR4 sustrate dielectric loss - generally at 0.02, the dielectric loss will increase with the increase of frequency.

TC value of FR4 substrate: also known as glass state transformation temperature, generally 130℃, 140℃, 150℃, 170℃.

2. Normal thickness of FR4 sheet

Normal thickness: 0.3m, 0.4m, 0.5mm, 0.6mm, 0.8mm, 1.0m, 1.2mm, 1.5mm, 1.6m, 1.8mm, 2.0mm, the thickness error of the plate is determined according to the production capacity of the plate factory.

FR4 copper clad plate commonly used copper thickness: 0.5 oz, 1 oz, 2 oz, other copper thickness, pls kindly to consult us.

Bicheng devote to supplying PCBs over 18 years with stable and strict quality gurantee, which service cellular base station antenna, satellite, high frequency passive components, microstrip line and band line circuit, millimeter wave equipment, radar system, digital radio frequency antenna and other fields wordwide. We are mainly providing high frequency PCBs which built on 3 high frequency material brands: Rogers Corporation, Taconic and Wangling. Dielectric constant ranges from 2.2 to 10.2 etc.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com