The Introduction of Rogers RO4000 Series Material

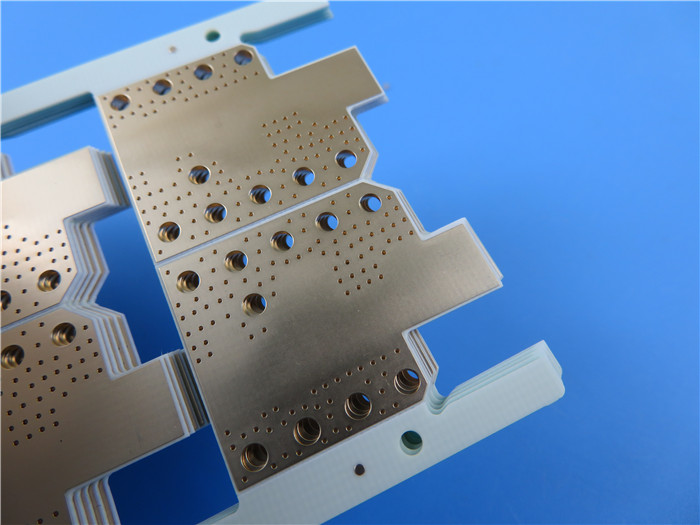

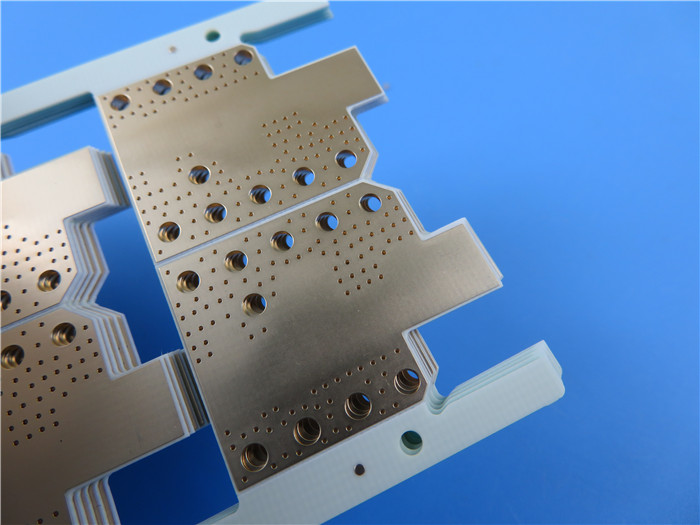

Rogers' RO4000 series of hydrocarbon and ceramic packed laminates and semi-cured sheets offer industry-leading high frequency performance and low circuit processing costs, a material that is compatible with FR-4 processing processes, including PCB multilayer structures, without the need for special hole pretreatments similar to sodium etching. The RO4000 material has the characteristics required for microwave RF circuits, matching networks, and specific impedance transmission line design. RO4000? Series products provide dielectric constant of 2.55~6.15 and low z-axis thermal expansion coefficient, with better heat treatment ability than traditional PTFE material, compatible with lead-free welding process, and in accordance with UL 94 V-0 fire rating version. RO4000 series products are ideal for P2P, RFID, LNB and other applications. The introduction of model selection of RO4000 series is as follows:

RO4000 LoPro laminate

=RO4000 LoPro laminate uses Rogers' patented technology so that the treated reversed copper foil can be compared to the standard RO4000? Together, the substrate has lower conductor losses while improving heat treatment capabilities, resulting in lower insertion losses and better signal consistency, while retaining other advantages of the RO4000 series materials. The low dielectric loss makes the RO4000 series suitable for many high frequency applications where traditional circuit boards cannot meet the requirements. The dielectric constant of the material is stable over a wide frequency range, so it is an ideal substrate for broadband applications.

Product features:

Lower insertion loss for higher operating frequency design (support frequency up to 40GHz)

Passive intermodulation (PIM) values are lower for base station antennas

RO4003C laminate

RO4003C is a patent glass woven reinforced hydrocarbon resin system/ceramic filler material, its electrical properties are very close to PTFE/ woven glass cloth material, and the workability is similar to epoxy resin/glass cloth material. The RO4003C provides a tightly controlled dielectric constant and loss at a fraction of the price of traditional microwave materials and requires no special through hole treatment or operation procedures. RO4003C is available in two different types of glass cloth 1080 and 1674, but both meet the same laminate electrical specifications. Suitable for high reliability aerospace, microwave/RF applications.

Product features:

Dielectric constant: 3.55@8GHz~40GHz

Tangent of dielectric loss Angle: 0.0027@10GHz/23℃

Standard epoxy/glass cloth processing can be used

RO4350B laminate

The basic performance of RO4350B is similar to that of RO4003C. It is worth mentioning that the fire rating of RO4350B reaches UL 94 V-0. RO4350B? Suitable for P2P, RFID, LNB, automotive radar and other applications.

Product features:

Dielectric constant: 3.66@8GHz~40GHz

Tangent of dielectric loss Angle: 0.0037@10GHz

RO4360G2 laminate

RO4360G2 laminate is a glass fiber reinforced ceramic filled hydrocarbon thermosetting material, is the perfect combination of high performance and easy to work. RO4360G2 is compatible with automatic mount, meet lead-free process capacity, improve machinability in multilayer board structure by increasing hardness, while reducing the cost of materials and processing, and help reduce circuit size. In the design of multi-layer board can be matched with RO4400 series of adhesive sheet and RO4000 series of material mixing. Suitable for power amplifier, patch antenna and other general rf components.

Product features:

Dielectric constant: 6.15@ 8GHz~40GHz

Z-axis thermal expansion coefficient: 28ppm/℃

Glass state transition temperature Tg: > 280 ℃

RoHS certified environmental protection products

RO4500 laminate

The RO4500 high frequency laminate layer family includes RO4533, RO4534 and RO4535. Its resin system provides the necessary performance for ideal antennas with dimensional stability of less than 0.05%. It is an affordable alternative to traditional antenna materials, providing a cost and performance balance solution for antenna products. The thermal expansion coefficient of RO4500 in X and Y directions is similar to that of copper, which can reduce the stress in PCB antenna. Based on the above characteristics, RO4500 series is very suitable for antenna products based on PRINTED circuit board design, such as WiMAX antenna network.

Product features:

Z-axis thermal expansion coefficient: 35,37,46 PPM /℃

Excellent Passive Intermodulation (PIM) from LoPro Copper Foil

Higher mechanical hardness than PTFE material

RO4700 laminate:

The thermal expansion coefficient of RO4700 antenna laminate is similar to that of copper in both X and Y directions, which can reduce the stress in PCB antenna. The thermal expansion coefficient of Z-axis is low, which reduces the risk of plated through hole fracture. The resin system of the laminate can provide the necessary properties for ideal antennas, making it a cost-effective alternative to PTFE antenna materials.

Product features:

Dielectric constant: 2.55, 3.0@2.5GHz

Glass state transition temperature: > 280 ° C (536 ° F)

Reducing the effect of passive intermodulation (PIM) : Eigenvalues < -164 dBc

Low insertion loss

RO4835 laminate

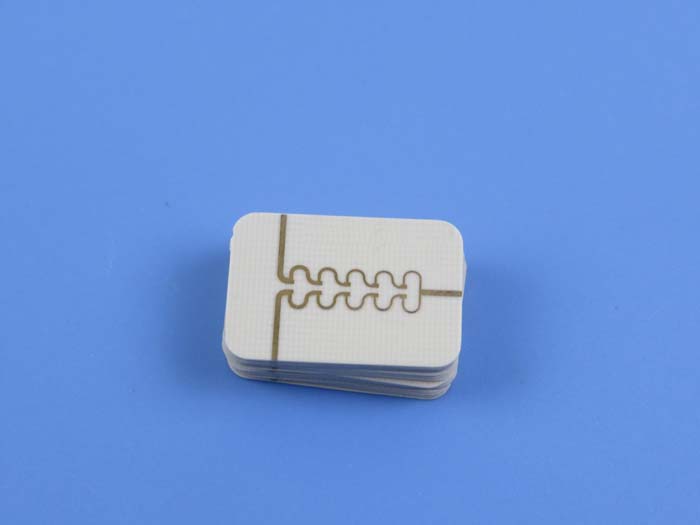

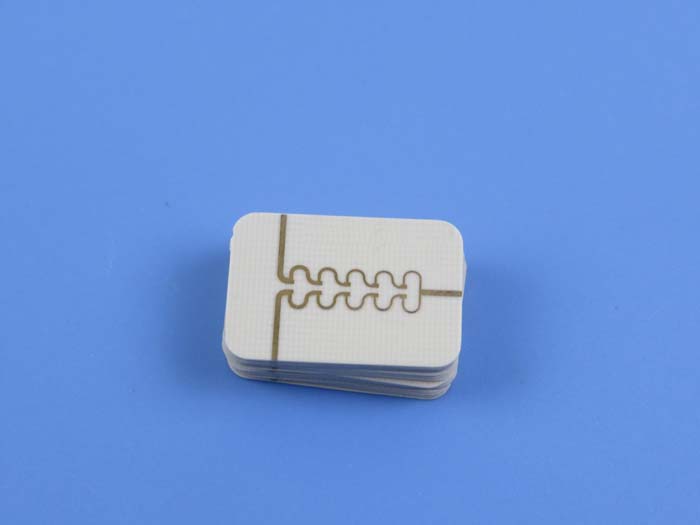

RO4835 laminate has excellent electrical performance, as a low loss material, but is fully compatible with FR-4 processing technology, providing excellent high-frequency performance and low line processing costs. RO4835 laminates offer 10 times more oxidation resistance than traditional thermosetting materials without bubbles or delamination. RO4835 laminates use RoHS compliant flame retardant technology for UL 94 V-0 applications. These materials meet the requirements of IPC-4103 and remain stable over the entire circuit processing temperature range. RO4835 laminates are suitable for applications requiring higher stability at high temperatures and greater oxidation resistance than standard RF thermosetting materials, such as phased array radars, automotive sensors, point-to-point transmission, etc.

Product features:

Dielectric constant: 3.66@8GHz~40GHz

Coefficient of thermal expansion:

-- X-axis: 10 PPM /℃

-- Y-axis: 12 PPM /℃

-- Z-axis: 31 PPM /℃

Ro4835 + IT180 DHI high frequency mixer plate. JPG

RO4450F Adhesive sheet (semi-cured sheet)

RO4450F is based on RO4000 series laminate material high frequency bonding sheet, and RO4003C, RO4350B can be laminated multilayer, can be compatible with most of the standard FR4 processing process. RO4450F bonding sheet can be lead-free welded and has a fire rating of UL-94 V-0.

Bicheng devote to supplying PCBs over 18 years with stable and strict quality gurantee, which service cellular base station antenna, satellite, high frequency passive components, microstrip line and band line circuit, millimeter wave equipment, radar system, digital radio frequency antenna and other fields wordwide. We are mainly providing high frequency PCBs which built on 3 high frequency material brands: Rogers Corporation, Taconic and Wangling. Dielectric constant ranges from 2.2 to 10.2 etc.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com