What Are the Advantages of Using RT/duroid 6035HTC OverTraditional PCB Materials for High-powerApplications?

In the realm of high-power RF and microwave applications, the introduction of Rogers RT/duroid 6035HTC high frequency circuit materials marks a pivotal moment. These ceramic-filled PTFE composites are engineered to excel in scenarios demanding exceptional performance and reliability. Let's delve deep into the world of RT/duroid 6035HTC and uncover how this innovative PCB is set to redefine the standards of high-power circuit design.

RT/duroid 6035HTC: A Paradigm Shift in High-Frequency Circuit Design

Rogers 6035HTC stands out in the landscape of high-frequency circuit materials. Engineered as a superior choice for high-power RF and microwave applications, these laminates boast a remarkable thermal conductivity that surpasses standard RT/duroid 6000 products by nearly 2.4 times. The incorporation of copper foil with exceptional long-term thermal stability further cements its position as a top-tier choice for demanding applications.

Key Features at a Glance

1)DK:

With a dielectric constant of 3.5 +/- 0.05 at 10 GHz/23°C, RT/duroid 6035HTC ensures stable and reliable signal propagation.

2)Dissipation Factor:

At 10 GHz/23°C, the dissipation factor of 0.0013 guarantees efficient energy transfer within the circuit.

3)Thermal Coefficient:

A thermal coefficient of dielectric constant of -66 ppm/°C ensures consistent performance across varying temperatures.

4)Moisture Absorption:

With a mere 0.06% moisture absorption rate, the PCB maintains its integrity even in challenging environmental conditions.

5)Thermal Conductivity:

A thermal conductivity of 1.44 W/m/K at 80°C facilitates effective heat dissipation, crucial for high-power operations.

6)CTE:

The Coefficient of Thermal Expansion in the X, Y, and Z axes ensures dimensional stability under thermal stress.

Benefits of Choosing RT/duroid 6035HTC

1)High Thermal Conductivity:

RT duroid 6035HTC's enhanced thermal conductivity translates to improved heat dissipation, enabling lower operating temperatures for high-power applications.

2)Optimized Dielectric Heat Dissipation:

The PCB's design promotes efficient heat dissipation, leading to enhanced performance and reliability in high-power scenarios.

3)Superior High-Frequency Performance:

Expect lower insertion loss and exceptional thermal stability of traces, ensuring consistent signal integrity.

What are the advantages of using RT/duroid 6035HTC over traditional PCB materials for high-power applications?

Using RT/duroid 6035HTC Laminate PCB over traditional PCB materials for high-power applications offers a range of advantages that cater specifically to the demands of such scenarios. Here are some key advantages of opting for RT/duroid 6035HTC in high-power applications:

1. Enhanced Thermal Conductivity:

Advantage: RT/duroid 6035HTC boasts a high thermal conductivity of 1.44 W/m/K at 80°C, facilitating efficient heat dissipation.

2. Improved Heat Management:

Advantage: The superior thermal conductivity of RT/duroid 6035HTC helps in managing heat effectively, allowing for lower operating temperatures in high-power applications.

3. Superior Signal Integrity:

Advantage: The precise dielectric properties of RT/duroid 6035HTC ensure stable signal propagation, leading to enhanced performance and reliability.

4. Low Losses:

Advantage: RT/duroid 6035HTC exhibits low insertion loss, making it ideal for high-power RF and microwave applications where signal integrity is crucial.

5. Consistent Performance Across Temperatures:

Advantage: The exceptional thermal stability of RT/duroid 6035HTC ensures consistent performance across a wide range of operating temperatures.

6. Moisture Resistance:

Advantage: With a low moisture absorption rate of 0.06%, RT/duroid 6035HTC Roger PCB maintains its integrity even in humid environments, ensuring long-term reliability.

7. Cost-Effective Drilling:

Advantage: The advanced filler system of RT/duroid 6035HTC enables cost-effective drilling compared to traditional high thermally conductive laminates using alumina fillers.

8. Design Flexibility:

Advantage: RT/duroid 6035HTC rogers circuit board material offers design flexibility, allowing for the creation of intricate high-power circuit layouts with precise trace geometries.

9. Compatibility with High-Frequency Applications:

Advantage: RT/duroid 6035HTC is specifically engineered for high-power RF and microwave applications, ensuring compatibility with high-frequency circuits.

10. Reliability in High-Power Environments:

Advantage: The combination of thermal performance, signal integrity, and durability makes RT/duroid 6035HTC a reliable choice for high-power applications.

11. Ease of Sourcing:

Advantage: RT/duroid 6035HTC Rogers high frequency laminates PCBs are readily available worldwide, ensuring easy access for projects requiring high-quality high-power circuit materials.

In summary, the advantages of using RT/duroid 6035HTC Rogers substrate over traditional PCB materials for high-power applications lie in its superior thermal conductivity, heat management capabilities, signal integrity, reliability, and cost-effectiveness. These characteristics make RT/duroid 6035HTC high frequency circuit board a top choice for engineers and designers seeking optimal performance and efficiency in high-power RF and microwave circuit designs.

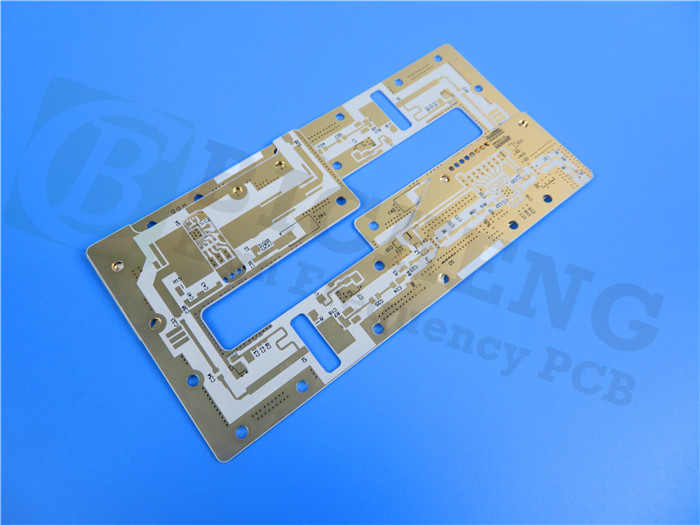

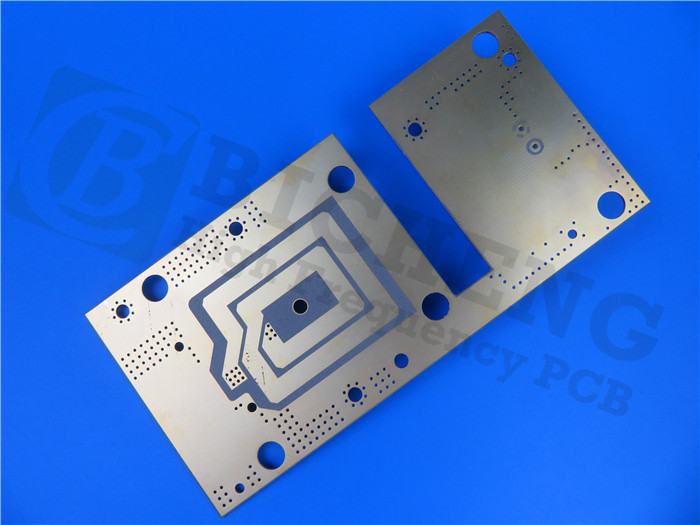

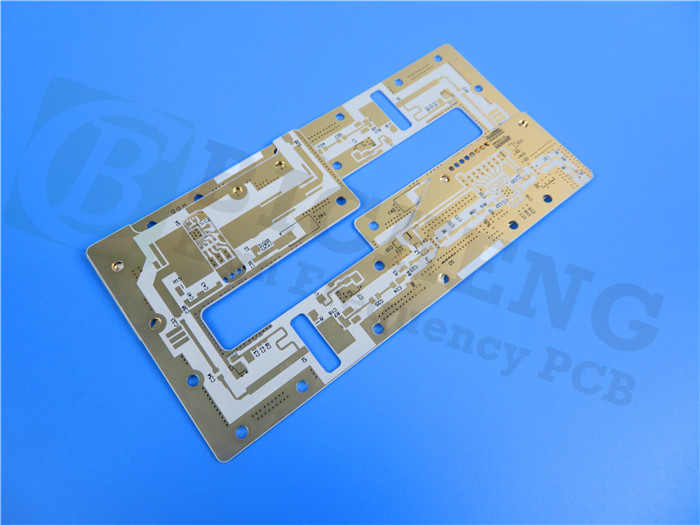

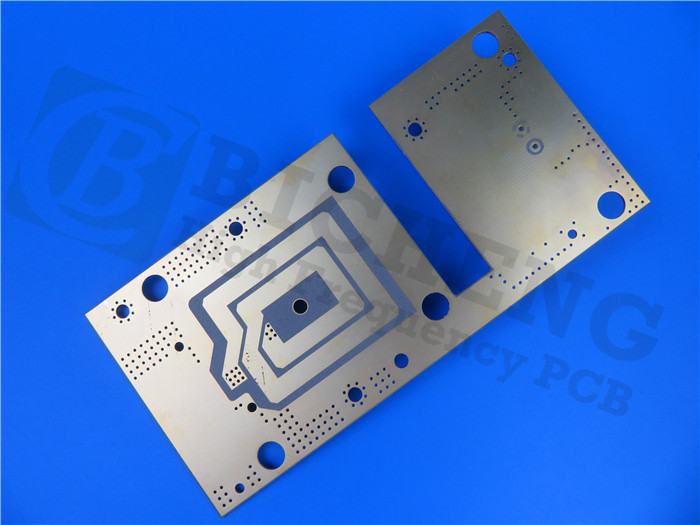

Exploring theRT/duroid 6035HTC PCB Construction and Stackup

PCB Stackup

Layers: 2-layer rigid PCB

Copper Thickness: 35 μm on each layer

RT/duroid 6035HTC Thickness: 0.254 mm (10mil)

10mil RT/duroid 6035HTC PCB Construction Details

Board Dimensions: 42.91mm x 108.31mm

Trace/Space: Minimum of 4/5 mils

Hole Size: Minimum 0.3mm

Finished Board Thickness: 0.3mm

Finished Cu Weight: 1oz (1.4 mils) on outer layers

Via Plating Thickness: 20 μm

Surface Finish: Immersion Gold

Silkscreen: Top - Black; Bottom - None

Solder Mask: None on both sides

Electrical Test: 100% conducted prior to shipment

PCB Statistics

Components: 35

Total Pads: 112

Thru Hole Pads: 74

Top SMT Pads: 38

Bottom SMT Pads: 0

Vias: 64

Nets: 2

Quality Assurance and Standards

Artwork Format: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Global Availability and Applications

Availability: RT/duroid 6035HTC Rogers PCB material are readily available worldwide, ensuring accessibility for diverse projects and applications.

Typical Applications Include

High-power RF and microwave amplifiers

Power amplifiers, couplers, filters, combiners, power dividers

Conclusion

In conclusion, the RT/duroid 6035HTC high frequency PCB emerges as a cornerstone in high-power RF and microwave circuit design. Its exceptional thermal conductivity, high-frequency performance, and robust construction make it a go-to choice for applications demanding reliability, efficiency, and superior performance. Embrace the future of high-power circuitry with RT/duroid 6035HTC PCBs, where innovation meets excellence.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com