Introduction

Established in 2003, Bicheng PCB is a well-known supplier and exporter of high frequency PCBs in Shenzhen, China. We have been serving various industries such as cellular base station antenna, high frequency passive components, microstrip line and band line circuit, millimeter wave equipment, radar systems, and digital radio frequency antenna for over 19 years.

Our high frequency PCBs are primarily manufactured using three main material brands: Rogers Corporation, Taconic, and China Wangling. The dielectric constant of these materials ranges from 2.2 to 10.2.

RF PCB Brands

Here are some of the materials we use, although this list is not exhaustive. Each brand offers different series of products.

Rogers offers the RO3000 series, RO4000 series, RT/duroid 5000 series, and RT/duroid 6000 series. They also have the AD series, DiClad, CuClad, and TMM series.

Taconic has the TLX series, RF series, and TLY series. They offer materials for base station antennas, satellite communication terminal antennas, high power amplifiers, and millimeter wave RF backplanes.

Wangling, a 38-year-old brand, is an alternative and competitive RF material manufacturer in various industries such as aerospace and aviation, satellite communication, navigation and radar, electronic countermeasure, and 4G and 5G communication. Their main product lines include F4B (PTFE) and composite dielectric substrates.

|

Brands

|

Series

|

Designation

|

|

Rogers

|

RO3000

|

RO3003, RO3006, RO3010, RO3035, RO3203, RO3210

|

|

RO4000

|

RO4350B, RO4003C, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO4835

|

|

RO5000

|

RT/Duriod 5880; RT/Duriod 5870, RT/duroid 5880LZ

|

|

RO6000

|

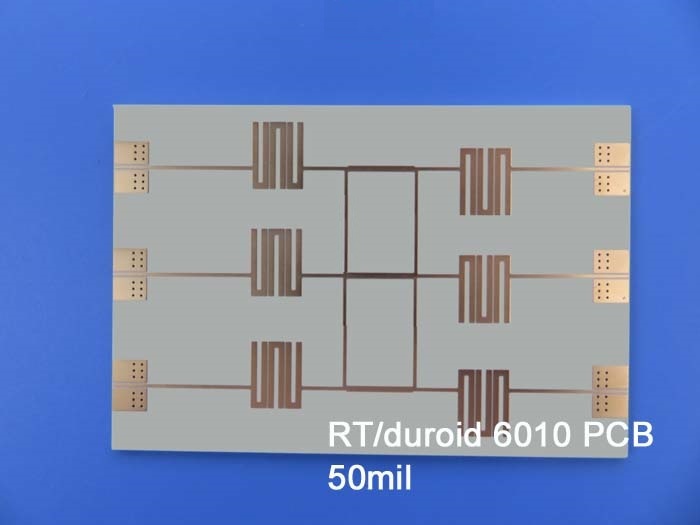

RT/Duriod 6002, RT/Duroid 6010, RT/duroid 6035HTC

|

|

AD Series

|

AD250C, AD255C, AD300D, AD350A, AD450, AD600, AD1000

|

|

DiClad

|

DiClad 880, DiClad 870, DiClad 527; CuClad250; CLTE-XT etc.

|

|

TC Series

|

TC350; TC600; Kappa 438

|

|

TMM

|

TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i

|

|

Taconic

|

TLY

|

TLY-3, TLY-5, TLY-5A, TLY-5Z etc.

|

|

TLX

|

TLX-6, TLX-7, TLX-8; TLX-9, TLX-0

|

|

TLF

|

TLF-35

|

|

RF

|

RF-35TC, RF-60A, RF-60TC, RF-35A2, RF-45, RF-10

|

|

TRF

|

TRF-45

|

|

Wangling

|

F4B-1/2

|

F4B255, F4B265

|

|

F4BM(E )-1/2

|

F4BME217, F4BME220, F4BM245, F4BME255, F4BME265, F4BME275, F4BME285, F4BME295, F4BME300

|

|

F4BMX-1/2

|

F4BMX217, F4BMX220, F4BMX245, F4BMX255, F4BMX265, F4BMX275, F4BMX285. F4BMX294, F4BMX300

|

|

F4BM(E )-2-A

|

F4BME-2-A255, F4BME-2-A265, F4BME-2-A275, F4BME-2-A285, F4BME-2-A294, F4BME-2-A300

|

|

F4BTM(E )-1/2

|

F4BTME255, F4BTME265, F4BTME285, F4BTME294, F4BTME300, F4BTME320, F4BTME338, F4BTME350, F4BTME400, F4BTME440, F4BTME615

|

|

WL Series

|

WL-CT300,WL-CT330, WL-CT330Z, WL-CT338, WL-CT350, WL-CT440, WL-CT615

|

|

TP /TF

|

TP1020, TF1020, TFA1020

|

Rogers RF PCB

Now, let's discuss the specific properties of each material.

The RO3000 series from Rogers are ceramic-filled PTFE composites that provide consistent mechanical properties and electrical stability. This series allows designers to develop multi-layer board designs using different dielectric constant materials for individual layers, without encountering warpage or reliability issues. Additionally, the RO3000 series has a stable dielectric constant over a wide temperature range, making it suitable for commercial microwave and RF applications.

Rogers RO4000 series materials are woven glass reinforced hydrocarbon ceramic laminates. They offer well-controlled dielectric constants in a wide range (2.55-6.15). These materials have above-average thermal conductivity, low Z-axis CTE for reliable plated through-hole connections, and optimized cost and RF/microwave performance.

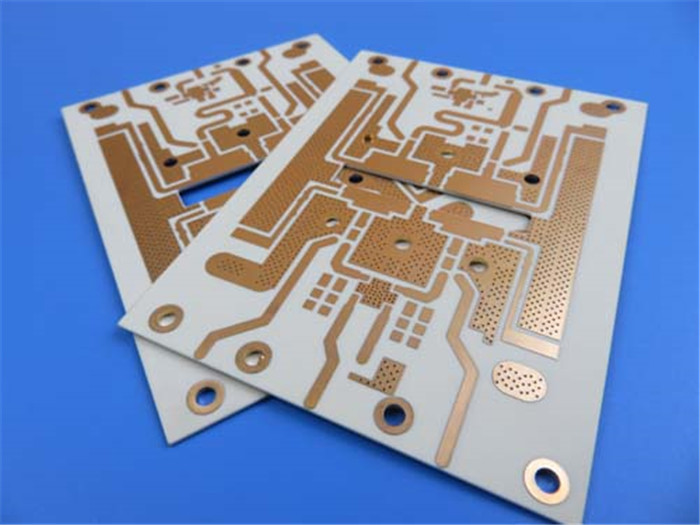

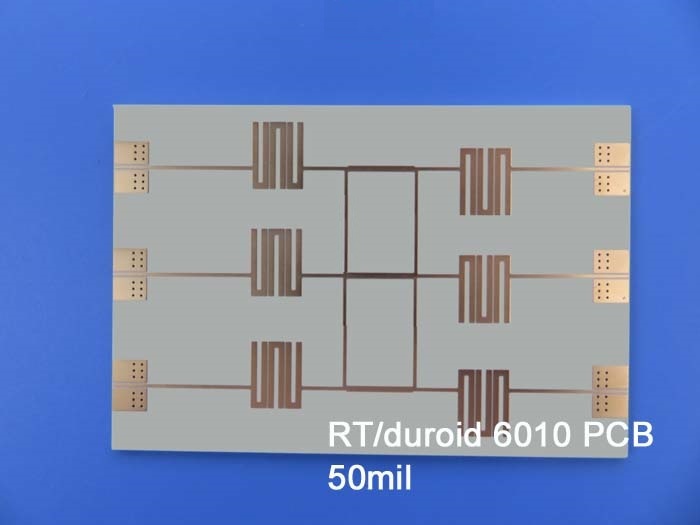

Rogers RT/duroid high frequency circuit materials come in the 5000 series and 6000 series. These materials are random glass or ceramic filled PTFE composite laminates used in high reliability aerospace and defense applications. They have low electrical loss, low moisture absorption, low outgassing for space applications, and stable dielectric constant over a wide frequency range.

The AD series and CLTE series from Rogers have low dielectric constant values ranging from 2.5 to 3, except for AD1000 material which has a value of 10.2.

The CuClad, DiClad, and IsoClad laminates from Rogers have much lower dielectric constants (Dk) ranging from 2.17 to 2.40. They also have lower electrical loss and moisture absorption.

The TC series from Rogers are woven glass reinforced PTFE ceramic composites with higher thermal conductivity. These materials provide higher power handling, reduce hot-spots, and improve device reliability in high power applications. They have a stable dielectric constant across a wide temperature range, low loss tangent at 10 GHz, and low coefficient of thermal expansion.

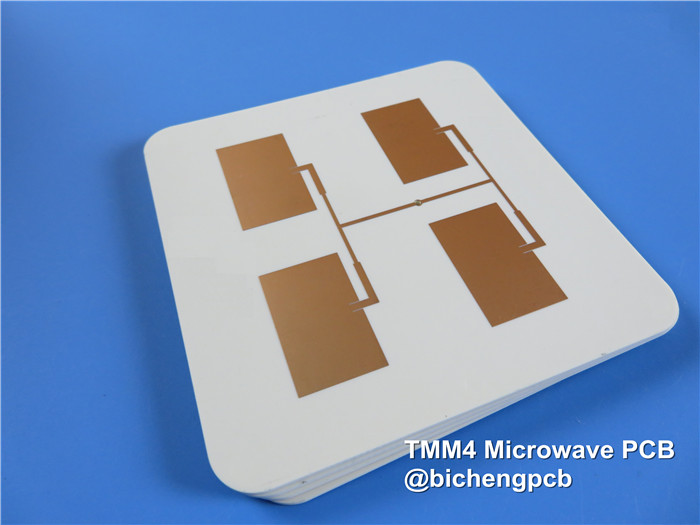

The TMM series from Rogers are hydrocarbon ceramic thermoset microwave laminates. These materials have exceptionally low thermal coefficient of dielectric constant (TCDk), a wide range of dielectric constants, copper-matched CTE, and dielectric constant uniformity. The TMM series exhibits excellent electrical and mechanical stability, resistance to creep and cold flow, making them ideal for strip-line and micro-strip applications.

Taconic RF PCB

Now, let's move on to Taconic materials.

Taconic offers high frequency materials based on ceramic-filled PTFE, woven-glass reinforced PTFE, and thermoset resin.

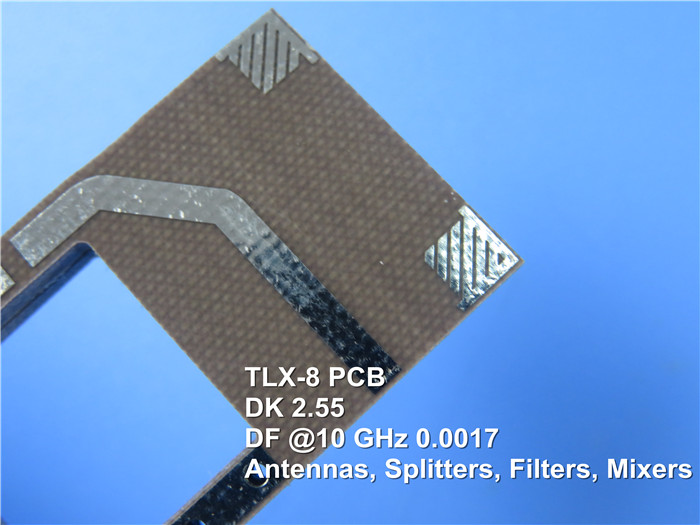

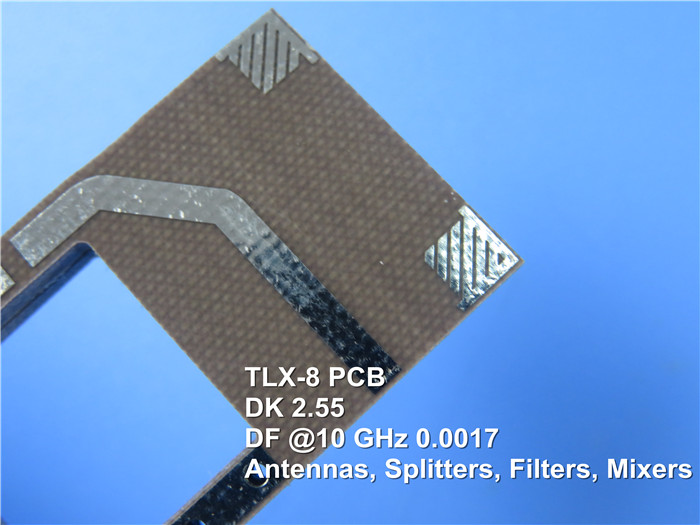

The TLX series from Taconic is versatile with a DK range of 2.45-2.65. It has a low dissipation factor and low water absorption. The CTE on the X and Y axis is similar to copper, offering reliability in a wide range of RF applications.

Materials like RF-10, RF-60TC, and CER-10 from Taconic are high DK materials that are useful in circuit size design. The "TC" materials have good thermal management properties, with RF-35TC having a thermal conductivity of 0.95 W/mK and RF-60TC having a thermal conductivity of 1.05 W/mK.

The TLY series from Taconic are manufactured with lightweight woven fiberglass and are dimensionally stable. These materials have very low Dk and low dissipation factor, making them suitable for automotive radar applications and other millimeter wave antennas.

Wangling RF PCB

Finally, let's discuss the details of Wangling materials.

Wangling offers a variety of high frequency materials that can be custom made. They continuously enhance the structure of their materials to meet market demands. Here are some of the most commonly used materials in the industry.

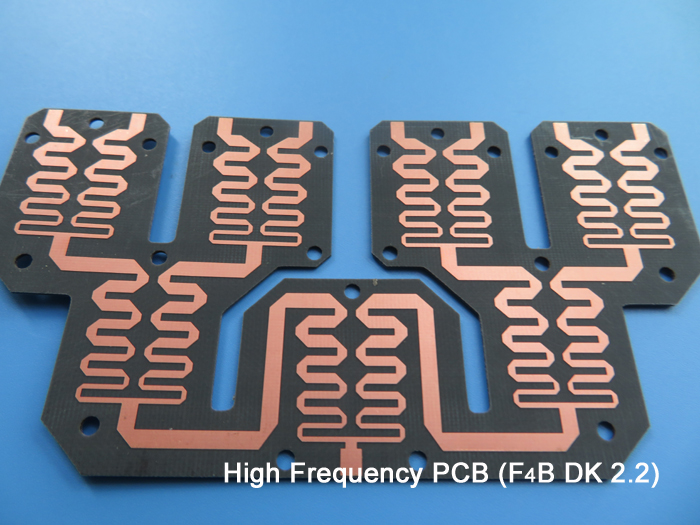

The F4B series includes materials such as F4B-1/2, F4BME-1/2, F4BMX-1/2, F4BME-2-A, and F4BTME-1/2. These materials offer excellent electrical performance, higher mechanical strength, low dissipation factor, and enhanced resistance values.

The TP and TF series are high DK materials with dielectric constants as high as 22. TP is a composite of ceramics, while TF is a composite of PTFE materials. These materials have CTE values similar to copper, low water absorption, and excellent dimensional stability.

The WL-CT series is made of organic polymer, ceramic filler, and glass fiber. These thermoset materials have a wide range of DK values and low dissipation factors. They exhibit excellent dimensional stability and plated through-hole reliability, even in severe thermal environments.

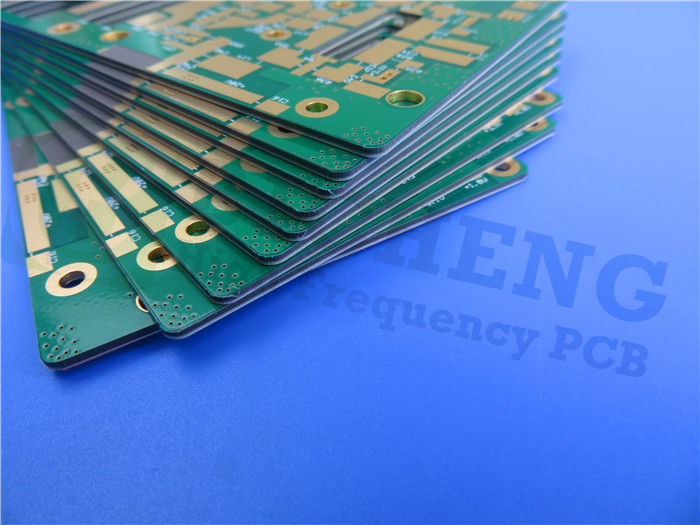

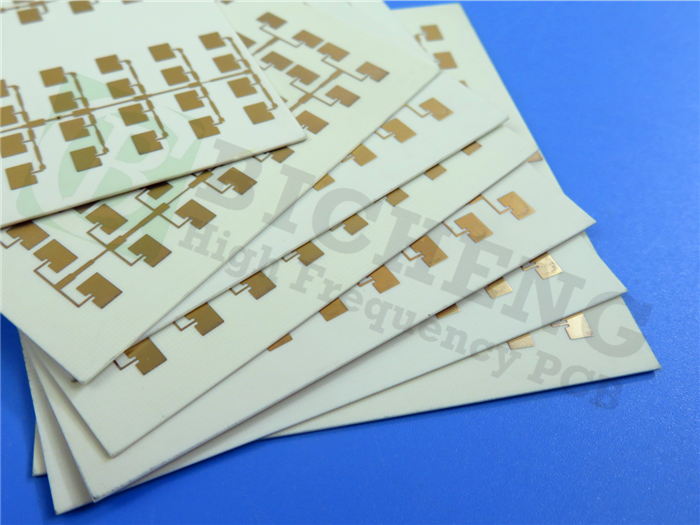

RF PCB Show

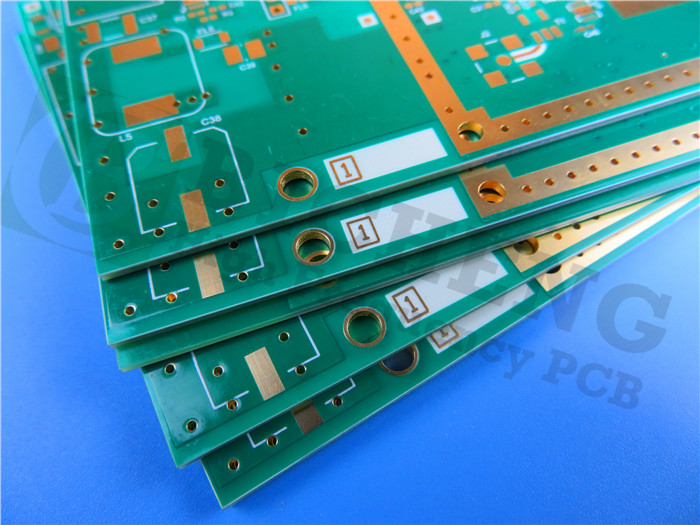

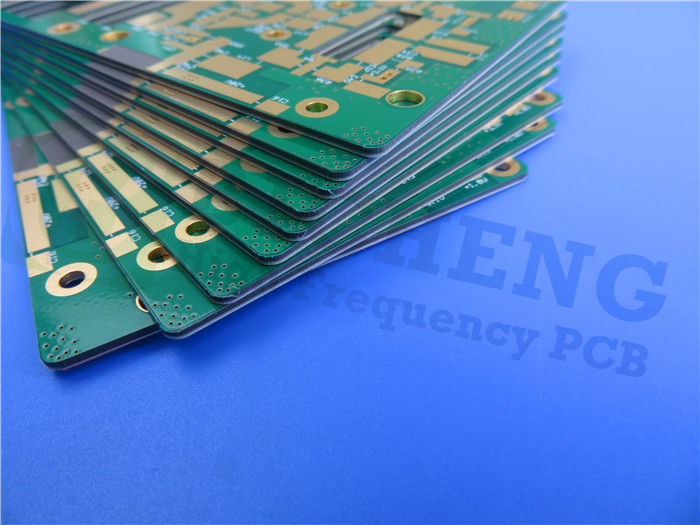

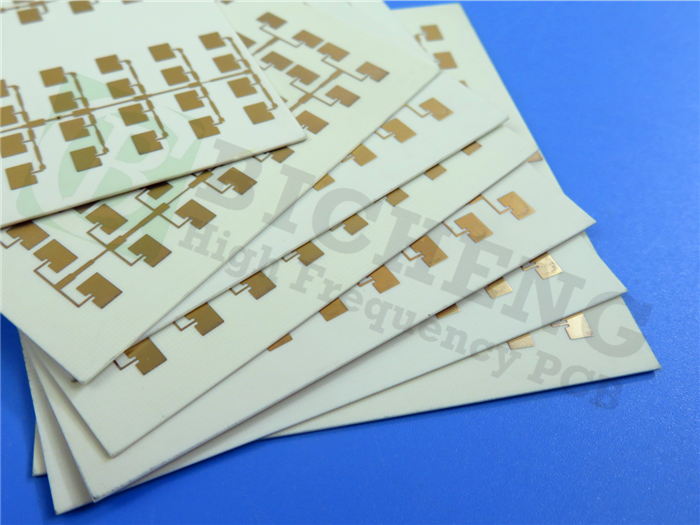

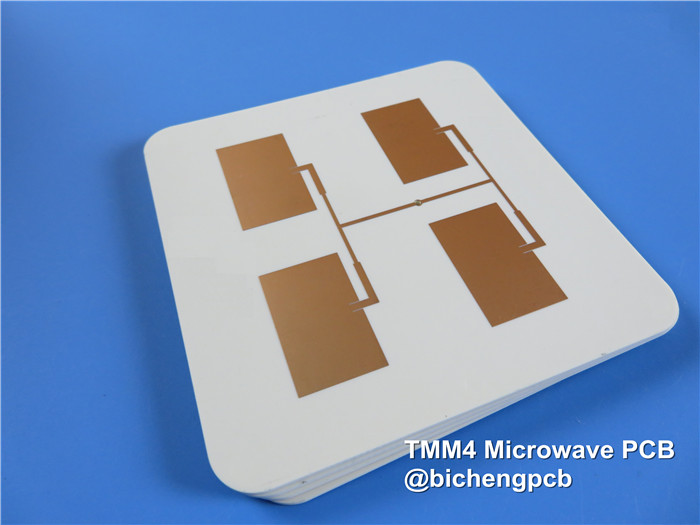

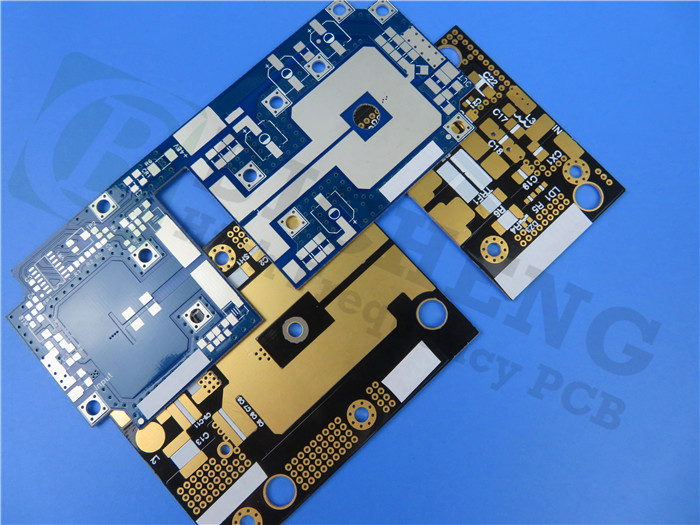

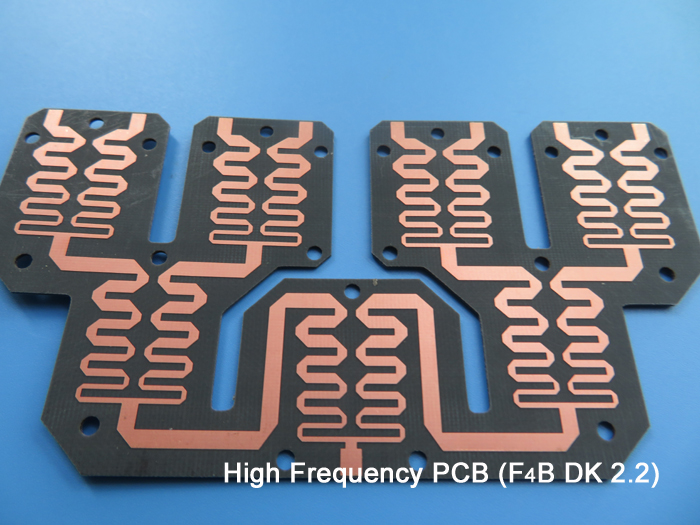

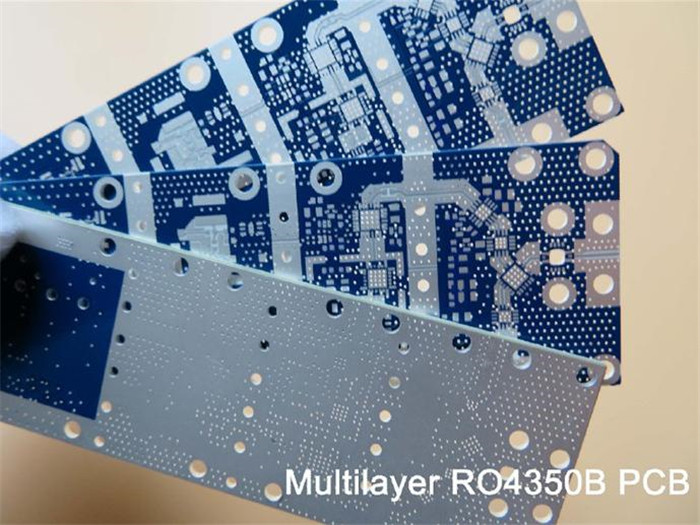

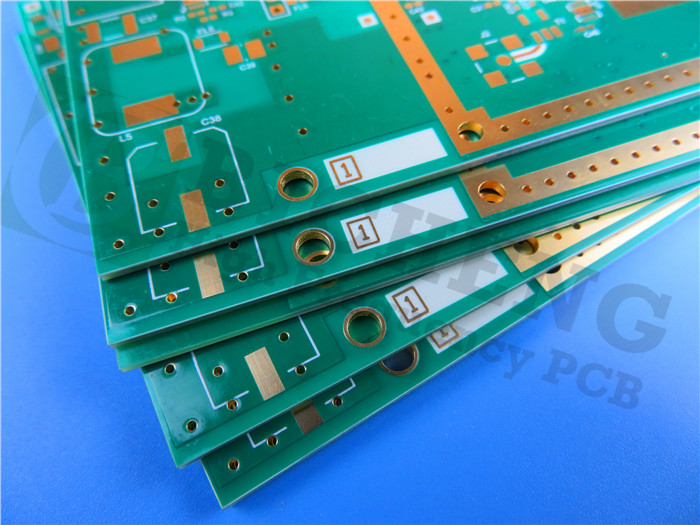

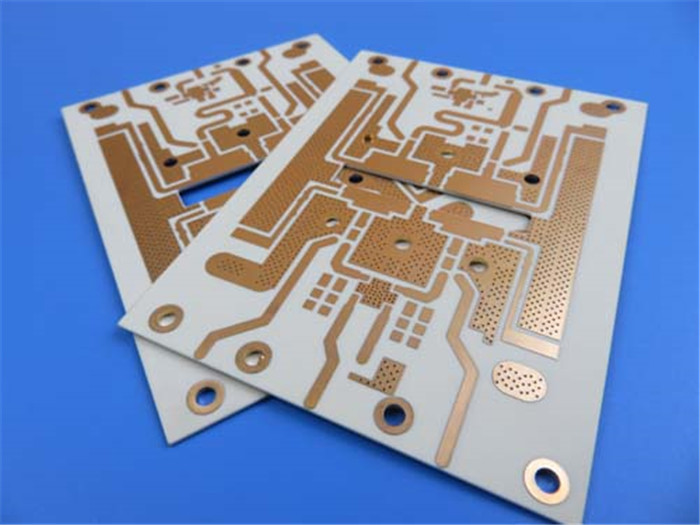

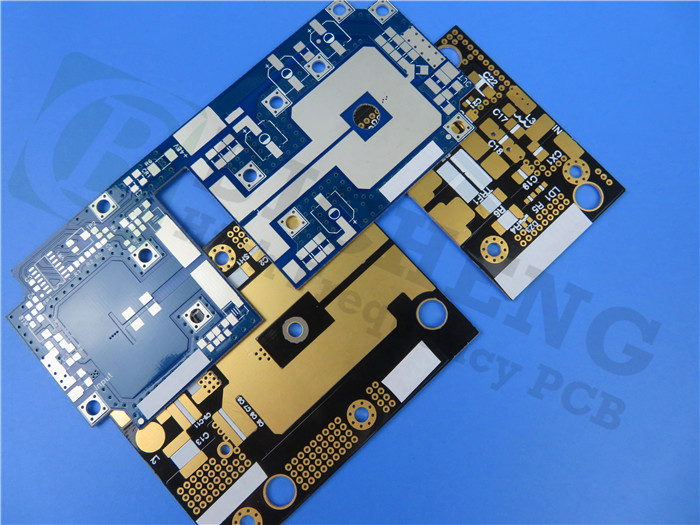

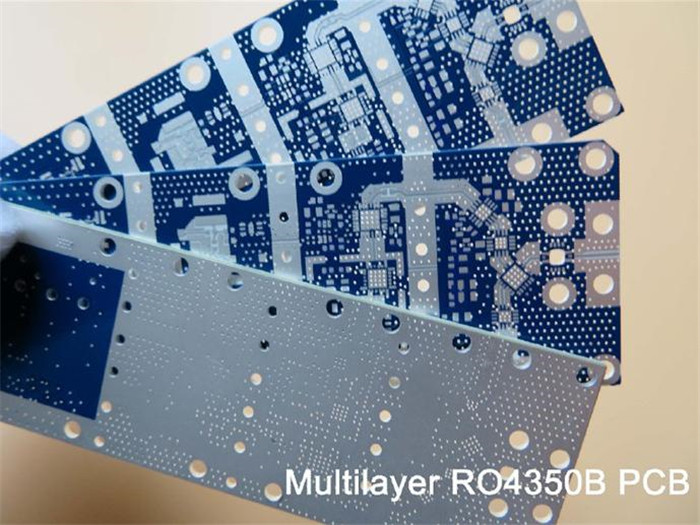

Here are some images of the printed circuit boards we manufacture:

1. RO3003 High Frequency PCB

2. RO4003C PCB

3. RT/duroid 5880 RF PCB

4. RT/duroid 6010 PCB

5. Kappa 438 High Frequency PCB

6. TMM4 High Frequency PCB

7. TLX-8 PCB

8. RF-35TC High Frequency PCB

9. F4B PCB

10. Multilayer RF PCB

PCB Capability (RF PCB)

For high frequency PCBs, we offer single layer, double layer, multi-layer, and hybrid types. The PCB outline can be mechanically routed or laser cut, especially for thin laminates of 5mil or 10mil. Vias can be tented by solder mask or plugged by resin and capped on the surface. They can also be blinded or buried in multilayer build-up. Finished copper thickness options include 1oz and 2oz.

Our maximum PCB size for high frequency materials is 400mm by 500mm. We can manufacture a single board or different designs within the same panel. We offer solder mask colors such as green, black, blue, red, and yellow.

For the final metal surface, we offer options such as immersion gold, HASL, immersion silver, and immersion tin, which have all been successfully applied to the surface SMD pads.

|

PCB material:

|

High Frequency substrates from Rogers, Tanoic and Wangling brands.

|

|

Dielectric constant:

|

2.2~10.2 @10 GHz

|

|

Dissipation factor:

|

0.005 ~ 0.0009 @10 GHz

|

|

Layer count:

|

1-layer, 2-layer, multi-layer, hybrid designs

|

|

Contour:

|

Mechanical routing, Laser cutting.

|

|

PCB Thickness:

|

0.2mm ~ 12.0mm

|

|

Via disposal:

|

via tenting / via filled and capped, blind via, buried via

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Red, Yellow, matt color etc.

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, Pure gold, ENEPIG, OSP etc..

|

Conclusion

When ordering a high frequency PCB, it is crucial to specify the basic specifications mentioned above, including the material designation, dielectric thickness, copper weight, surface finishes, and stack-up information if it is a multilayer PCB.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com