TMM4 PCB 5.08mm substrate : A High-Frequency Solution with Exceptional Performance

Introduction:

Today, we will be discussing TMM 4, a high frequency PCB that is constructed using thermoset microwave material.

Rogers TMM 4 PCB is a composite made of ceramic, hydrocarbon, and thermoset polymer. This combination of materials provides it with strong mechanical and chemical properties, incorporating the advantages of both ceramic and traditional PTFE materials. The use of thermoset resins ensures reliable wire-bonding without any pad lifting or substrate deformation.

TMM4 possesses a range of impressive properties that make it an excellent choice for demanding applications. Let's take a closer look at some of its key features.

TMM4 Typical Properties

Firstly, let's talk about the Dielectric Constant of TMM4. At 10 GHz, it has a process value of 4.5±0.045, ensuring reliable signal transmission. During the design phase, the Dielectric Constant is 4.7, covering a broad frequency range from 8 GHz to 40 GHz.

Moving on to the Dissipation Factor, TMM4 excels with a process value of 0.002 at 10 GHz, indicating low signal loss and improved performance.

TMM4 also exhibits exceptional thermal stability. The Thermal Coefficient of the dielectric constant is +15 ppm/°K over a wide temperature range from -55°C to 125°C.

In terms of electrical properties, TMM4 impresses with an Insulation Resistance exceeding 2000 Gohm, ensuring reliable insulation performance. The Volume Resistivity measures an impressive 6 x 10^8 Mohm.cm, while the Surface Resistivity stands at 1 x 10^9 Mohm.

Now let's discuss the thermal properties of TMM4. It has a Decomposition Temperature (Td) of 425°C, ensuring stability and reliability even at high temperatures.

The Coefficient of Thermal Expansion of TMM4 is also worth noting. Along the X axis, it measures 16 ppm/K, along the Y axis, it measures 16 ppm/K, and along the Z axis, it measures 21 ppm/K. This means that TMM4 can withstand temperature variations from 0°C to 140°C without significant dimensional changes.

Additionally, TMM4 has a Thermal Conductivity of 0.7 W/m/K at 80°C, enabling efficient heat dissipation in electronic systems.

Moving on to its mechanical characteristics,RogersTMM4 material PCB showcases remarkable strength. The Copper Peel Strength after Thermal Stress reaches an impressive 5.7 lb/inch (1.0 N/mm) for both X and Y directions, even after solder float with 1 oz. EDC.

TMM4's Flexural Strength stands at 15.91 kpsi in both the MD (Machine Direction) and CMD (Cross-Machine Direction), ensuring structural integrity in demanding conditions. The Flexural Modulus for MD and CMD is 1.76 Mpsi, indicating excellent stiffness.

TMM4 also exhibits desirable physical properties. Its Moisture Absorption is minimal, with only 0.07% for a 2X2 area at 1.27mm (0.050") thickness and 0.18% at 3.18mm (0.125") thickness.

The Specific Gravity of TMM4 is 2.07, providing a lightweight solution without compromising performance. Additionally, its Specific Heat Capacity is 0.83 J/g/K, contributing to efficient thermal management.

Lastly, TMM4 is Lead-Free Process Compatible, ensuring compliance with industry standards and environmental regulations.

TMM4 PCB Capability:

Now let's move on to the capabilities of TMM4 PCBs. We offer single layer boards, double layer boards, multi-layer boards, and hybrid types.

TMM4 PCBs come in a wide range of thicknesses, including standard thicknesses such as 20 mils, 30 mils, 50 mils, and 60 mils, as well as non-standard thicknesses such as 15 mils, 25 mils, 75 mils, and 125 mils. Our designers can create boards as thin as 15 mils and as thick as 500 mils.

The finished copper on the PCB can be 1oz, 2oz, or 3oz. The maximum PCB size on high frequency materials is 400mm by 500mm, allowing for single boards or different designs within a panel.

We offer solder mask options in green, black, blue, yellow, and more. Pads plating options include immersion gold, HASL, immersion silver, immersion tin, pure gold, and bare copper.

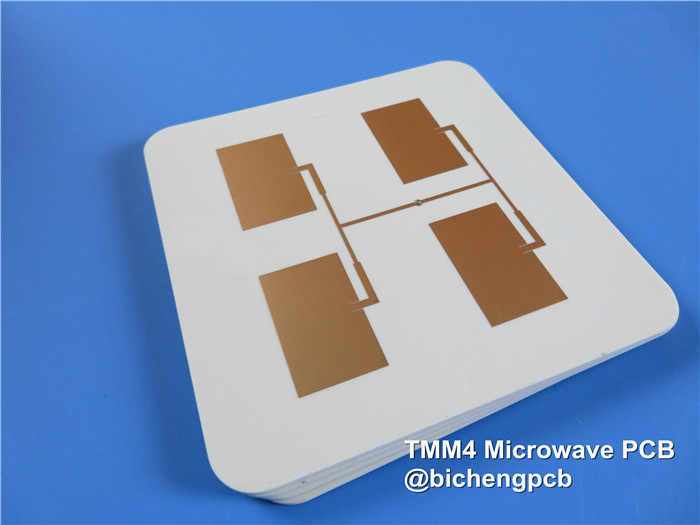

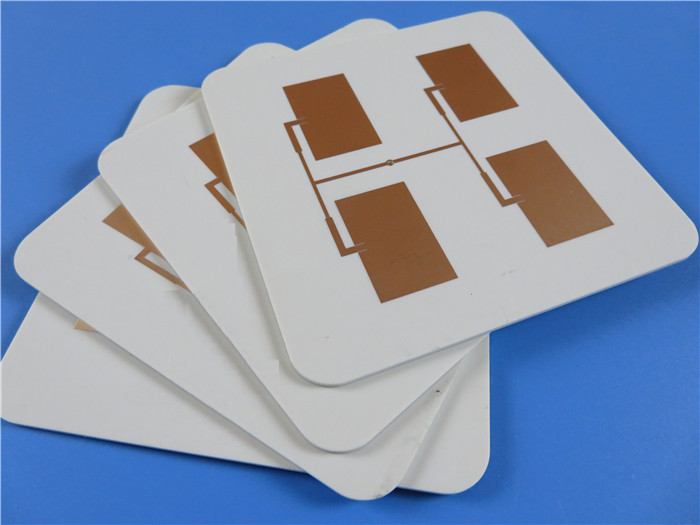

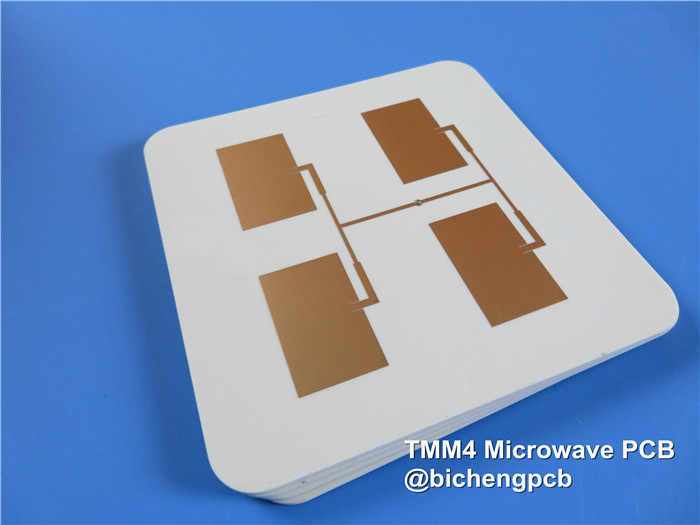

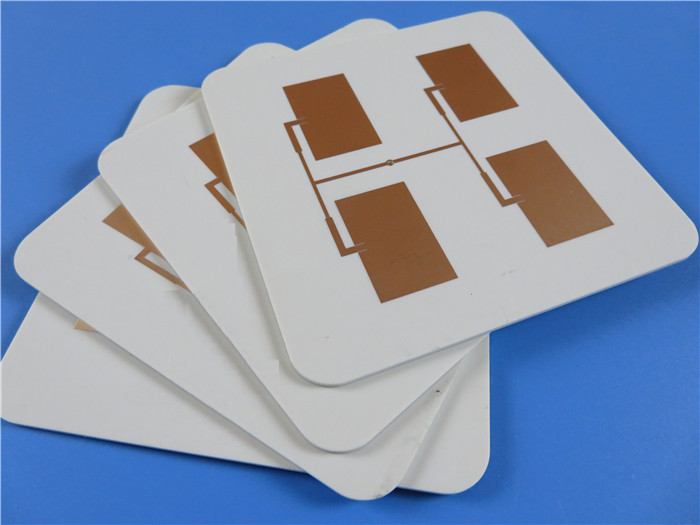

There is a double layer TMM4 PCBs on 5.08mm Rogers substrate without solder mask. TMM 4 PCBs are typically used in power amplifiers and combiners, filters and couplers, satellite communication systems, GPS antennas, dielectric polarizers and lenses etc.

Applications:

TMM4 PCBs are commonly used in power amplifiers and combiners, filters and couplers, satellite communication systems, GPS antennas, dielectric polarizers, and lenses.

Conclusion:

In conclusion,TMM4 high frequency PCBs exhibit excellent mechanical and chemical properties, making them resistant to creep and cold flow. They are also resistant to process chemicals, reducing damage during fabrication. TMM4 materials are compatible with common PCB manufacturing processes, allowing for volume mass production.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com