Are you in search of a high-performance PCB that delivers exceptional signal integrity, superior dimensional stability, and efficient heat dissipation? Look no further than the AD1000 PCB, a revolutionary product designed to meet the demands of modern electronic applications. In this article, we delve deep into the features, benefits and properties of the

AD1000 25mil material PCB, providing you with all the information you need to make an informed decision.

AD1000 PCB Material: Unleashing Exceptional Performance

The AD1000 PCB is crafted using a woven glass reinforced PTFE/ceramic filled laminate, setting it apart from conventional options. With ahigh Dielectric Constant (Dk) of 10.2 at 10 GHz/23°C, a dissipation factor of 0.0023 at 10 GHz/23°C, and a thermal coefficient of Dk of -380 ppm/°C, this PCB material ensures outstanding electrical performance and stability. Additionally, it operates flawlessly in temperatures ranging from -40℃ to +85℃, making it suitable for a wide range of applications.

Benefits:

l Mechanically Robust: With enhanced mechanical strength, the AD1000 PCB resists warping or damage during handling and assembly.

l Greater Dimensional Stability: This PCB offers exceptional dimensional stability compared to other 10 Dk products, ensuring reliable performance over time.

l Circuit Miniaturization and Weight Savings: The AD1000 PCB enables compact designs and reduces weight, making it ideal for applications with space constraints.

l Heat Dissipation and Management: Efficient heat dissipation properties contribute to the longevity and reliability of electronic components.

l Greater Signal Integrity: Low loss and high dielectric constant minimize signal degradation, ensuring reliable transmission in high-frequency applications.

l Cost-Effective Board Layout and Processing: The AD1000 PCB allows for cost-effective design, layout, and manufacturing processes.

l Resilience in Humid Environments: Its low loss characteristics make it suitable for applications in humid environments.

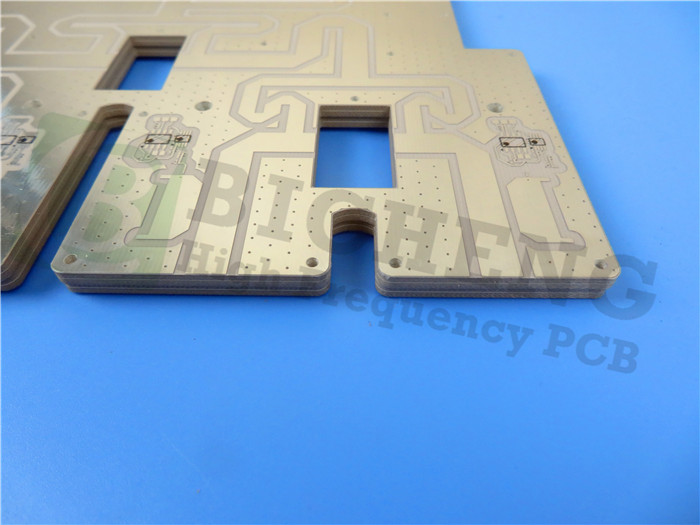

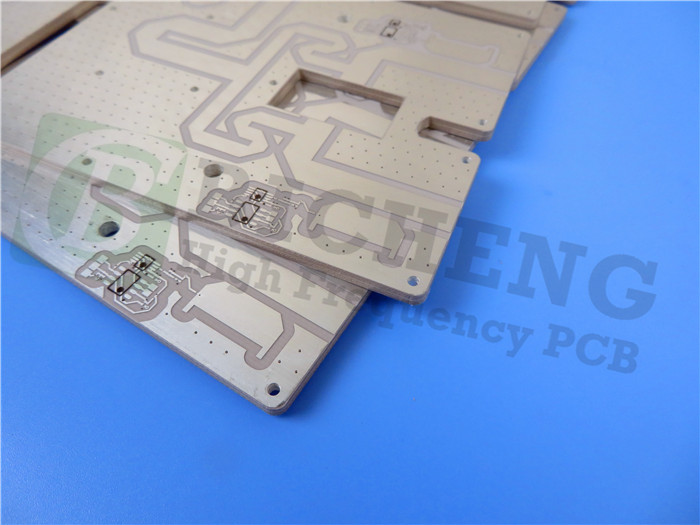

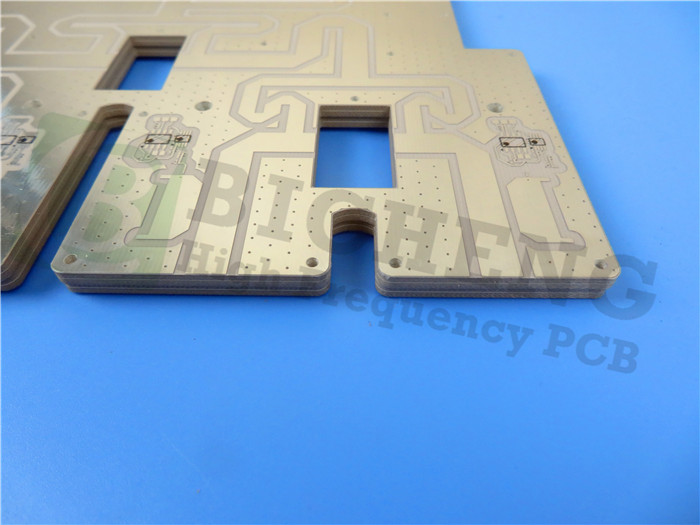

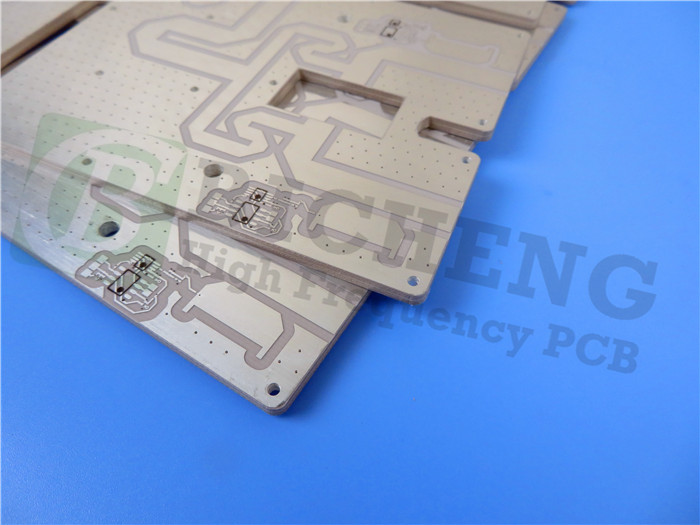

Construction Details:

l 2-layer rigid PCB with copper layer thickness of 35 μm on each side.

l Rogers Core AD1000 with a thickness of 0.635 mmsubstrate (25mil).

l Finished board dimensions of 114.6mm x 56.9mm with a tolerance of +/- 0.15mm.

l Minimum trace/space of 6/5 mils and a minimum hole size of 0.38mm.

l Finished board thickness of 0.8mm with 1 oz (1.4 mils) outer layer copper weight.

l Via plating thickness of 20 μm and immersion gold surface finish.

l No silkscreen or solder mask layers are applied.

l Rigorously tested with a 100% electrical test prior to shipment.

The AD1000 PCB is a high-performance circuit board that offers excellent electrical, thermal, mechanical, and physical properties. Let's go through the data sheet and understand its key characteristics:

Electrical Properties:

Volume Resistivity: It measures the resistance of the material to the flow of electric current. The values are 1.40x10^9 MΩ-cm (C96/35/90) and 5.36x10^7 MΩ-cm (E24/125).

Surface Resistivity: It measures the resistance of the material's surface to the flow of electric current. The values are 1.80x10^9 MΩ (C96/35/90) and 3.16x10^8 MΩ (E24/125).

Electrical Strength: It indicates the maximum electric field the material can withstand without breaking down. The value is 622 volts/mil (24.5 kV/mm).

Dielectric Breakdown: This property represents the voltage at which the material experiences a catastrophic failure. The value is greater than 45 kV.

Arc Resistance: It measures the ability of the material to resist the formation and growth of an electric arc. The value is greater than 180 seconds.

Thermal Properties:

Decomposition Temperature: It indicates the temperature at which the material begins to decompose. The initial and 5% decomposition temperatures are both greater than 500°C.

T260, T288, T300: These values represent the minimum time in minutes that the material can withstand exposure to temperatures of 260°C, 288°C, and 300°C, respectively.

Thermal Expansion (CTE): It measures the expansion or contraction of the material with temperature. The CTE values are 8 ppm/℃ (x, y direction) and 20 ppm/℃ (z direction).

% z-axis Expansion: This property represents the percentage of expansion along the z-axis in the temperature range of 50-260°C.

Mechanical Properties:

Peel Strength to Copper: It measures the strength of the bond between the material and a copper surface. The values are provided for different conditions: after thermal stress, at elevated temperatures (150º), and after process solutions.

Young's Modulus: It indicates the stiffness of the material. The value is 200 kpsi (1.38 GPa).

Flexural Strength: It measures the material's ability to withstand bending. The values are provided for machine and cross directions: 9.9/7.5 kpsi (68/52 MPa).

Tensile Strength: It represents the material's resistance to breaking under tension. The values are provided for machine and cross directions: 5.1/4.3 kpsi (35/30 MPa).

Compressive Modulus: It measures the material's ability to withstand compressive forces. The value is greater than 425 kpsi (>2.93 GPa).

Poisson's Ratio: It indicates the ratio of lateral strain to axial strain under an applied load. The value is 0.16.

Physical Properties:

Water Absorption: It represents the material's ability to absorb water. The value is 0.03%.

Density: It indicates the mass per unit volume of the material at ambient temperature (23ºC). The value is 3.20 g/cm3.

Thermal Conductivity: It measures the material's ability to conduct heat. The value is 0.81 W/mK.

Flammability: The material meets the V0 flammability class according to UL-94 standards.

NASA Outgassing: It measures the release of volatile substances under specific conditions. The values for total mass loss, collected volatiles, and water vapor recovered are 0.01%, 0.00%, and 0.00%, respectively, at 125ºC and ≤10-6 torr.

These properties make the AD1000 PCB a reliable and high-quality choice for various electronic applications where excellent electrical performance, thermal stability, mechanical strength, and low outgassing are required.

Worldwide Availability and Support

The AD1000 25mil PCB is available worldwide, allowing customers from any corner of the globe to benefit from its exceptional features. For any technical inquiries or questions, our dedicated sales representative, Jane, can be reached at sales20@bichengpcb.com. Feel free to contact her for personalized assistance and guidance.

Applications That Excel with the AD1000 PCB

The AD1000 PCB finds its ideal applications in various industries and projects, including:

-

X-Band and Below: The PCB's high-performance characteristics make it perfect for X-Band and sub-X-Band applications, ensuring reliable and accurate signal transmission.

-

Radar Modules and Manifolds: The AD1000 PCB is well-suited for radar modules and manifolds, delivering exceptional performance and stability.

-

Aircraft Collision Avoidance Systems (TCAS): With its mechanical robustness and low loss in humid environments, the AD1000 PCB is an excellent choice for TCAS systems, enhancing aviation safety.

-

Ground-Based Radar Surveillance Systems: The AD1000 PCB's superior signal integrity and dimensional stability make it an ideal solution for ground-based radar surveillance systems, ensuring accurate and consistent results.

-

Miniaturized Circuitry and Patch Antennas: The AD1000 PCB enables miniaturization of circuitry and the development of patch antennas, allowing for compact and efficient designs.

-

Power Amplifiers (PAs): The Rogers AD1000 PCB's excellent heat dissipation and management capabilities make it suitable for power amplifier applications, preventing overheating and ensuring optimal performance.

-

Low Noise Amplifiers (LNAs): With its low loss and superior signal integrity, the AD1000 PCB is ideal for low noise amplifier applications, providing clean and reliable signal amplification.

In conclusion, the AD1000 high dielectric constant laminate PCB sets a new standard for high-performance circuit boards. With its woven glass reinforced PTFE/ceramic filled laminate material, exceptional electrical properties, and robust construction, it delivers unmatched reliability, signal integrity, and heat dissipation. Whether you're working on radar systems, aviation projects, or miniaturized circuitry, the AD1000 PCB is your go-to solution.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com